Abstract

Pressure-tunable reaction media possess unique tunability of the physical and transport properties. This manuscript highlights how such media may be exploited for developing resource-efficient chemical technologies characterized by process intensification, high product selectivity, enhanced safety and facile separation steps. Alternative technology conceptsfor p-xylene oxidation and ozonolysis that employ pressuretunable media to demonstrate such process attributes are highlighted. Techno-economic and life cycle analyses reveal that the alternative processes possess process, economic and environmental benefits relative to incumbent technologies. Process intensification allows modularization of reactors and other unit operations, which is especially well suited for processing stranded or distributed resources such as biomass and shale gas to produce fuels and chemical intermediates.

Similar content being viewed by others

References

Global Chemical Outlook (GCO), United Nations Environment Programme (UNEP), 2012. http://www.unep.org/pdf/GCO_Synthesis%20Report_ CBDTIE_ UNEP_September5_2012.pdf. Accessed May 10, 2017.

IEA, Energy Technology Perspectives 2012. OECD/IEA, Paris, 2012. https://www.iea.org/publications/freepublications/publication/ETP2012_free.pdf. Accessed May 10, 2017.

IEA. http://www.iea.org/publications/freepublications/publication/Chemical_Roadmap_2013_Final_WEB.pdf. Accessed May 10, 2017.

http://www.ecofys.com/files/files/asn-ecofys-2013-world-ghg-emissions-flow-chart-2010.pdf. Accessed May 10, 2017.

Anastas, P. and Warner, J.C., Green Chemistry: Theory and Practice, New York: Oxford Univ. Press, 1998.

Anastas, P. and Eghbali, N., Green chemistry: Principles and practice, Chem. Soc. Rev., 2010, vol. 39, p.301.

Anastas, P. and Zimmerman, J., Design through the 12 principles of green engineering, J. Environ. Sci. Technol., 2003, vol. 37, p.95.

Sheldon, R.A., Consider the environmental quotient, Chemtech, 1994, vol. 24, p.38.

Sheldon, R.A., Arends, I.W.C.E., and Hanefeld, U., Green Chemistry and Catalysis, Weinheim: Wiley-VCH, 2007.

Welton, T., Solvents and sustainable chemistry, Proc. R. Soc. A, 2015, vol. 471, p.502.

Tundo, P., Anastas, P., Black, D.S., Breen, J., Collins, T., Memoli, S., Miyamoto, J., Poliakoff, M., and Tumas, W., Synthetic pathways and processes in green chemistry–Introductory overview, Pure Appl. Chem., 2000, vol. 72, p. 1207.

DeSimone, J.M., Practical approaches to green solvents, Science, 2002, vol. 297, p.799.

Adams, D.J., Dyson, P.J., and Tavener, S.J., Chemistry in Alternative Reaction Media, Chichester: Wiley, 2004.

Eckert, C.A., Liotta, C.L., Bush, B., Brown, J.S., and Hallett, J.P., Sustainable reactions in tunable solvents, J. Phys. Chem. B, 2004, vol. 108, p. 18108.

Morgenstern, D.A., LeLacheur, R.M., Morita, D.K., Borkowsky, S.L., Feng, S., Brown, G.H., Luan, L., Gross, M.F., Burk, M.J., and Tumas, W., Supercritical carbon dioxide as a substitute solvent for chemical synthesis and catalysis, Green Chemistry: Designing Chemistry for the Environment, Anastas, P.T. and Williamson, T.C., Eds., ACS Symposium Series, vol. 626, Washington, DC: American Chemical Society, 1996, p.132.

Jessop, P.G. and Leitner, W., Chemical Synthesis Using Supercritical Fluids, Weinheim: Wiley-VCH, 1999.

Amandi, R., Hyde, J., and Poliakoff, M., Heterogeneous reactions in supercritical carbon dioxide, Carbon Dioxide Recovery and Utilization, Aresta, M., Ed., Dordrecht: Kluwer, 2003, p.169.

DeSimone, J.M. and Tumas, W., Green Chemistry Using Liquid and Supercritical Carbon Dioxide, New York: Oxford Univ. Press, 2003.

Gordon, C.M. and Leitner, W., Supercritical fluids as replacements for conventional organic solvents, Chimica Oggi, 2004, vol. 22, p.39.

Beckman, E.J., Using CO2 to produce chemical products sustainably, Environ. Sci. Technol., 2002, vol. 36, p.347.

Arai, M., Fujita, S.I., and Shirai, M., Multiphase catalytic reaction in/under dense phase CO2, J. Supercrit. Fluids, 2009, vol. 47, p.351.

Li, C.J. and Chan, T.H., Organic Reactions in Aqueous Media, New York: Wiley, 1997.

Cornils, B. and Herrmann, W.A., Aqueous-Phase Organometallic Catalysis, Weinheim: Wiley-VCH, 1998.

Savage, P.E., A perspective on catalysis in sub-and supercritical water, J. Supercrit. Fluids, 2009, vol. 47, p.407.

Jessop, P.G. and Subramaniam, B., Gas-expanded liquids, Chem. Rev., 2007, vol. 107, p. 2666.

Akien, G.R. and Poliakoff, M.A., Critical look at reactions in class I and II gas-expanded liquids using CO2 and other gases, Green Chem., 2009, vol. 11, p. 1083.

Scurto, A.M., Hutchenson, K.W., and Subramaniam, B., Gas-expanded liquids (GXLs): Fundamentals and applications, Gas-Expanded Liquids and Near-Critical Media: Green Chemistry and Engineering, Hutchenson, K.W., Scurto, A.M., and Subramaniam, B., Eds., ACS Symposium Series, vol. 1006, Washington, DC: American Chemical Society, 2009, p.3.

Wasserscheid, P. and Welton, T., Ionic Liquids in Synthesis, Weinheim: Wiley-VCH, 2002.

Rogers, R.D., Seddon, K.R., and Volkov, S., Green Industrial Applications of Ionic Liquids, Dordrecht: Kluwer, 2003.

Parvulescu, V.I. and Hardacre, C., Catalysis in ionic liquids, Chem. Rev., 2007, vol. 107, p. 2615.

Olivier-Bourbigou, H., Magna, L., and Morvan, D., Ionic liquids and catalysis: Recent progress from knowledge to applications, Appl. Catal., A, 2010, vol. 373, p.1.

Jessop, P.G., Mercer, S.M., and Heldebrant, D.J., CO2-triggered switchable solvents, surfactants, and other materials, Energy Environ. Sci., 2012, vol. 5, p. 7240.

Tomás, R.A.F., Bordado, J.C.M., and Gomes, J.F.P., p-Xylene oxidation to terephthalic acid: A literature review oriented toward process optimization and development, Chem. Rev., 2013, vol. 113, p. 7421.

Sheehan, R.J., Terephthalic acid, dimethyl terephthalate, and isophthalic acid, in Ullmann’s Encyclopedia of Industrial Chemistry, Weinheim: Wiley-VCH, 2003, vol. 35, 6th ed., p.639.

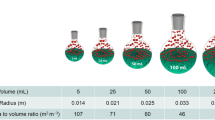

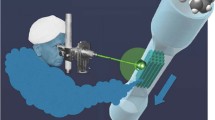

Li, M., Niu, F., Zuo, X., Metelski, P.D., Busch, D.H., and Subramaniam, B., A spray reactor concept for catalytic oxidation of p-xylene to produce high-purity terephthalic acid, Chem. Eng. Sci., 2013, vol. 104, p.93.

Lange, N., Lange’s Handbook of Chemistry, New York: McGraw-Hill, 1999, 15th ed.

Aspen HYSYS®, Version 7.1, Calgary, Alberta: Aspen Technologies, 2009.

Abrams, K.J., Process for preparing aromatic carboxylic acids with efficient energy recovery by the oxidation of aromatic hydrocarbon feedstocks, US Patent 5723656 A, 1998.

Osada, M. and Savage, P.E., Terephthalic acid synthesis at higher concentrations in high-temperature liquid water. 2. Eliminating undesired byproducts, AIChE J., 2009, vol. 55, no. 6, p. 1530.

Tashiro, Y., Iwahama, T., Sakaguch, S., and Ishii, Y., A new strategy for the preparation of terephthalic acid by the aerobic oxidation of p-xylene using N-hydroxyphthalimide as a catalyst, Adv. Synth. Catal., 2001, vol. 343, p.220.

Li, M., Ruddy, T., Fahey, D.R., Busch, D.H., and Subramaniam, B., Terephthalic acid production via greener spray process: Comparative economic and environmental impact assessments with mid-century process, ACS Sustainable Chem. Eng., 2014, vol. 2, p.823.

Bozell, J.J. and Petersen, G.R., Technology development for the production of biobased products from biorefinery carbohydrates–the US Department of Energy’s “Top 10” revisited, Green Chem., 2010, vol. 12, pp.539.

Gruter, G.J., The madness of green PET drop-in (from carbohydrates) versus the opportunities of its bio-PEF replacement, AIChE Netherlands/Belgium Section, Amsterdam, 2014. http://www.aiche.nl/images/presentations /2014-4-15-ldm.pdf. Accessed May 10, 2017.

Eerhart, A.J.J.E., Faaij, A.P.C., and Patel, M.K., Replacing fossil based PET with biobased PEF: Process analysis, energy and GHG balance, Energy Environ. Sci., 2012, vol. 5, p. 6407.

Zuo, X., Venkitasubramanian, P., Busch, D.H., and Subramaniam, B., Optimization of Co/Mn/Br-catalyzed oxidation of 5-hydroxymethylfurfural to enhance 2,5-furandicarboxylic acid yield and minimize substrate burning, ACS Sustainable Chem. Eng., 2016, vol. 4, no. 7, p. 3659.

Zuo, X., Chaudhari, A.S., Snavely, K.W., Niu, F., Zhu, H., Martin, K.J., and Subramaniam, B., Kinetics of 5-Hydroxymethylfurfural Oxidation to 2,5-Furandicarboxylic Acid with Co/Mn/Br Catalyst, AIChE J., 2017, vol. 63, no. 1, pp. 162–171. doi 10.1002/aic.15497

Subramaniam, B., Zuo, X., Busch, D.H., and Venkitasubramanian, P., Process for producing both biobased succinic acid and 2,5-furandicarboxylic acid, Patent WO 2013/033081 A2, 2013.

Criegee, R., Mechanism of ozonolysis, Agnew. Chem. Int. Ed., 1975, vol. 14, no. 11, p.745.

Lundin, M.D., Danby, A.M., Akien, G.A., Binder, T.J., Busch, D.H., and Subramaniam, B., Liquid CO2 as a Safer and Benign Solvent for the Ozonolysis of Fatty Acid Methyl Esters, ACS Sustainable Chem. Eng., 2015, vol. 3, no. 12, p. 3307.

Goebel, C.G., Brown, A.C., Oehlschlaegar, H.F., and Rolfes, R.P., Method of making azelaic acid, US Patent 2813113, 1957.

Patnaik, P., A Comprehensive Guide to the Hazardous Properties of Chemical Substances, Hoboken, N.J.: Wiley, 2007.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Subramaniam, B. Chemical Process Intensification with Pressure-Tunable Media. Theor Found Chem Eng 51, 928–935 (2017). https://doi.org/10.1134/S004057951706015X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S004057951706015X