Abstract

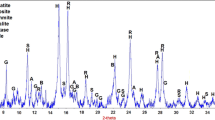

The sintering of basalt waste with sodium carbonate at 1000–1200°C followed by leaching of the sinter with water, a NaOH solution, or hydrochloric acid is reported. The most effective leaching agent is hydrochloric acid, with which all of the valuable components of basalt pass into solution and silicon can be selectively separated as silicic acid.

Similar content being viewed by others

References

Promyshlennost’ stroitel’nykh materialov (Constructional Materials Industry, Ser. 6, issue 1/2: Gabbro-bazal’tovoe syr’e dlya proizvodstva bazal’tovogo volokna (Gabbro-Basal Stocks for Producing Basalt Fiber), Raskina, E.M, and Zemtsov, A.N., Eds., Moscow, 2003.

Jefferi, P.G., Chemical Methods of Rock Analysis, Oxford: Perganob, 1970.

Babko, A.K. and Pyatnitskii, I.V., Kolichestvennyi analiz (Quantitative Analysis), Moscow: Goskhimizdat, 1956.

Chernyak, A.S., Khimicheskoe obogashchenie rud (Chemical Benefication of Ores), Moscow: Nedra, 1976.

Ni, L.P., Fizicheskaya khimiya gidroshchelochnykh protsessov polucheniya oksida alyuminiya (Physical Chemistry of Aqueous Leaching Processes for Alumina Recovery), Almaty: Kazgos INTI, 2001.

Troitskii, I.A. and Zheleznov, V.A., Metallurgiya alyuminiya (Aluminum Metallurgy), Moscow: Metallurgiya, 1984.

Babievskaya, I.Z., Dergacheva, N.P., Drobot, N.F., et al., Physicochemical Simulation of Fusion Processes of Basalt and Diabase with Na2CO3 and Na2CO3 + CaO, Inorg. Mater., 2010, vol. 46, no. 1, p. 65.

Ponomarev, V.D., Sazhin, V.S., and Ni, L.P., Gidrokhimicheskii shchelochnoi sposob pererabotki alyumosilikatov (Hydrochemical Alkaline Technology for Aluminosilicate Processing), Moscow: Metallurgiya, 1964.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © N.F. Drobot, O.A. Noskova, A.V. Steblevskii, S.V. Fomichev, V.A. Krenev, 2010, published in Khimicheskaya Tekhnologiya, 2010, Vol. 11, No. 9, pp. 536–542.

Rights and permissions

About this article

Cite this article

Drobot, N.F., Noskova, O.A., Steblevskii, A.V. et al. Recovery of valuable components from basalt waste by sintering it with sodium carbonate. Theor Found Chem Eng 45, 769–775 (2011). https://doi.org/10.1134/S004057951105006X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S004057951105006X