Abstract

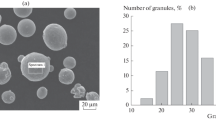

The structure formation in corrosion-resistant steel during laser melting is studied. The results of investigation of the morphology and the granulometric and chemical compositions of a CL20ES steel powder, which was prepared by melt dispersion with a high-pressure inert gas, are reported. It is shown that samples characterized by the highest density and microhardness are prepared using a converging laser beam.

Similar content being viewed by others

REFERENCES

E. C. Hussam, C. Bruno, S. Branchu, H. Xiaowei, J. Y. Hasco, and R. Guille, “Direct laser fabrication process with coaxial powder projection of 316L steel. Geometrical characteristics and microstructure characterization of wall structures”, Optics Lasers Eng. 50, 1779–1784 (2012).

K. Guan, Z. Wang, M. Gao, X. Li, and X. Zeng, “Effects of processing parameters on tensile properties of selective laser melted 304 stainless steel”, Mater. Design 50, 581–586 (2013).

C. Hauser, “Selective laser sintering of a stainless steel powder,” PhD Thesis (University of Leeds, 2003).

K. Kempen, L. Thijs, B. Vrancken, S. Buls, J. Van Humbeeck, and J.‑P. Kruth, “Producing crack-free, high density M2 HSS parts by selective laser melting: pre-heating the baseplate,” in Proceedings of the 24th International Solid Freeform Fabrication Symposium (Laboratory for Freeform Fabrication, Austin, 2013), pp. 131–139.

K. O. Bazaleeva, E. V. Tsvetkova, and E. V. Balakirev, “Recrystallization processes of austenite alloy prepared by selective laser melting,” Vestn. Bauman Mosk. Gos. Tekn. Univ., Ser. Mashinostr., No. 5, 117–127 (2016).

K. O. Bazaleeva, E. V. Tsvetkova, I. Yu. Smurov, I. A. Yadroitsev, E. V. Bazaleev, and Yu. G. Kostyuk, “Cellular structure in austenite alloys prepared by selective laser melting,” Perspektivnye Mater., No. 3, 55–62 (2014).

R. M. Kakhramanov, M. Yu. Kuprikov, L. N. Radinskii, and Yu. O. Solyaev, “Study of mechanical and structural characteristics of steel samples with a complexly shaped gage section, which were prepared by layer-by-layer laser synthesis,” Tekhnol. Met., No. 5, 27–33 (2016).

V. T. Musienko, “Regularities of granule formation upon centrifugal spraying of rotating blank,” in Metallurgy of Granules (Izd. VILS, Moscow, 1983), Vol. 1, pp. 41–48.

http:// www.conceptlaserinc.com/wp-content/uploads/2014/10/111123_CL-20ES.pdf.

Concept Laser GmbH. http://www.concept-laser.de.

Yu. A. Sokolov, L. E. Afanas’eva, I. A. Barabonova, M. V. Novoselova, and R. M. Grechskin, “Microstructure and properties of Ti–6Al–4V alloy prepared by layer-by-layer electron-beam synthesis technology,” Metalloved. Therm. Obrab. Met., No. 6 (720), 45–50 (2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Kolchugina

Rights and permissions

About this article

Cite this article

Ratkevich, G.V., Zhdanov, A.V., Belyaev, L.V. et al. Selective Laser Melting of Corrosion-Resistant Steel. Russ. Metall. 2019, 1433–1437 (2019). https://doi.org/10.1134/S0036029519130305

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029519130305