Abstract

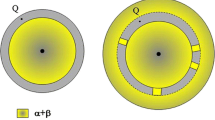

A phenomenological mathematical model of the formation and growth of phases in a binary multiphase system with allowance for factors influencing the process of diffusion in a binary system is presented. It is shown that phases can grow for a certain time at different ratios between diffusion parameters according to a parabolic law that depends on the duration of isothermic annealing. They then slow their growth after successor phases appear at their interface with one component and can completely disappear from a diffusion layer or begin to grow again, but only at a rate slower than during their initial formation. The dependence of the thickness of each phase layer in a multiphase diffusion zone on the duration of isothermic annealing and the ratio between the diffusion parameters in neighboring phases is obtained. It is established that a certain ratio between the phase growth and rates of dissolution with allowance for the coefficients of diffusion in each phase and the periods of incubation can result in the complete disappearance of one phase as early as the onset of the growth of phase nuclei and be interpreted as a process of reaction diffusion.

Similar content being viewed by others

References

C. Wagner and S. Schottky, Z. Phys. Chem. B 11, 163 (1930).

A. Fry, Stahl Eisen, 1039 (1923).

V. Z. Bugakov, Diffusion in Metals and Alloys (Gostekhizdat, Leningrad, 1949) [in Russian].

W. Seith, Diffusion in Metallen (Springer, Berlin, 1955).

S. D. Gertsriken and I. Ya. Dekhtyar, Diffusion in Metals and Alloys in Solid Phase (GIFML, Moscow, 1960) [in Russian].

L. N. Larikov, V. R. Ryabov, and V. M. Fal’chenko, Diffusion Processes in Solid-Phase Welding of Materials (Mashinostroenie, Moscow, 1975; Am. Publ., New York, 1984).

Yu. D. Tret’yakov, Solid-State Reactions (Khimiya, Moscow, 1978) [in Russian].

K. P. Gurov, B. A. Kartashkin, and Yu. E. Ugaste, Mutual Diffusion in Multiphase Metal Systems (Nauka, Moscow, 1981) [in Russian].

A. G. Zakharov, S. A. Bogdanov, Yu. B. Kakurin, and N. A. Kakurina, Inzh. Vestn. Dona 35 (2-1), 6 (2015).

N. F. Lashko and S. V. Lashko, Brazing of Metals (Mashinostroenie, Moscow, 1988) [in Russian].

L. I. Roslyakova and I. N. Roslyakov, Uprochn. Tekhnol. Pokryt., No. 4 (112), 32 (2014).

P. M. Robinson and M. B. Beaver, in Intermetallic Compounds, Ed. by J. H. Westbrook (Wiley, New York, 1967).

I. E. Petrunin, I. Yu. Markova, and A. S. Ekatova, Metallography of Brazing (Metallurgiya, Moscow, 1976) [in Russian].

V. A. Alekseev, A. F. Bykov, N. V. Gel’fond, et al., RF Patent No. 2082821 (1997).

S. G. Ivanov, M. A. Gur’ev, and A. M. Gur’ev, Aktual. Probl. Mashinostroen., No. 2, 416 (2015).

D. A. Prokoshkin, Element Diffusion in Solid Iron: Chemical and Thermal Methods of Steel Processing (Moscow, Leningrad, 1938) [in Russian].

A. P. Chernyshev and V. V. Ovchinnikov, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 2, 48 (1998).

F. van Loo and G. Rieck, Acta Metallurg. 21, 61 (1973).

M. Ganseen and G. Rieck, Trans. Met. Soc. AJME 239, 1372 (1967).

E. J. Clark, Welding J. 38, 251 (1959).

V. I. Borisov and V. T. Borisov, Fiz. Met. Metalloved. 42, 496 (1976).

A. I. Epishin, T. Link, A. O. Rodin, et al., Phys. Met. Metallogr. 116, 175 (2015).

A. R. Chelyadinskii, Vestn. Belorus. Univ., Ser. 1: Fiz. Mat. Inform., No. 2, 45 (2015).

L. A. Molokhina, Fiz. Khim. Obrab. Mater., No. 1, 123 (1986).

L. A. Molokhina, Fiz. Khim. Obrab. Mater., No. 2, 106 (1986).

S. G. Ekhilevskii, O. V. Golubeva, E. P. Potapenko, and S. A. Ol’shannikov, Vestn. Polots. Univ., Ser. C: Fundam. Nauki, No. 4, 94 (2015).

L. A. Molokhina, Svar. Proizvod., No. 6, 20 (1983).

L. A. Molokhina and Yu. S. Dolgov, in Increasing of Efficiency in Brazed Structures Production (MDNTP im. F.E. Dzerzhinskogo, Moscow, 1983), p. 30 [in Russian].

L. A. Molokhina and O. I. Tikhomirova, in Solders for Modern Materials Soldering (IES im. E. O. Patona, Kiev, 1985), p. 57 [in Russian].

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © L.A. Molokhina, V.E. Rogalin, S.A. Filin, I.A. Kaplunov, 2017, published in Zhurnal Fizicheskoi Khimii, 2017, Vol. 91, No. 9, pp. 1468–1475.

Rights and permissions

About this article

Cite this article

Molokhina, L.A., Rogalin, V.E., Filin, S.A. et al. Mathematical model for the growth of phases in binary multiphase systems upon isothermic annealing. Russ. J. Phys. Chem. 91, 1635–1641 (2017). https://doi.org/10.1134/S0036024417090217

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024417090217