Abstract

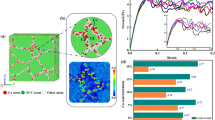

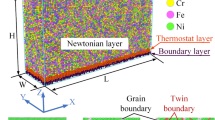

The effects of bismuth inclusion on the mechanical properties and deformation mechanisms of nanopolycrystalline iron under uniaxial tensile loading were investigated using molecular dynamics simulations. The analysis of the stress-strain behavior of polycrystalline pure Fe and alloy containing Bi inclusion shows that the Young’s modulus of the latter is lower, the strain into the yield stage is smaller, and the yield strength is significantly decreased. Microscopic analysis of pure Fe polycrystalline and Fe–Bi polycrystalline systems with small grain size shows that the deformation mechanisms of pure Fe polycrystalline systems are mainly grain boundary migration, grain boundary slip and grain twisting, while a limited amount of twinning can be observed. The deformation of Fe–Bi system is accomplished based on the deformation mechanism of pure Fe system combined with the shear slip of atoms in Bi inclusion and adjacent region. Meanwhile, the nucleation and growth of cavity can be observed inside the inclusion.

Similar content being viewed by others

DATA AVAILABILITY

Data will be made available on request.

REFERENCES

D. Lou, K. Cui, and Y. Jia, “Study on the machinability of resulfurized composite free-cutting steels,” J. Mater. Eng. Perform. 6, 215–218 (1997). https://doi.org/10.1007/s11665-997-0017-0

Z. Li and D. Wu, “Effect of free-cutting additives on machining characteristics of austenitic stainless steels,” J. Mater. Sci. Technol. 26, 839–844 (2010). https://doi.org/10.1016/s1005-0302(10)60134-x

Yu. Li, T. Suzuki, N. Tang, Yu. Koizumi, and A. Chiba, “Microstructure evolution of SUS303 free-cutting steel during hot compression process,” Mater. Sci. Eng., A 583, 161–168 (2013). https://doi.org/10.1016/j.msea.2013.06.069

Yi. Guo, Q. Wang, G. Chen, and S. He, “Castability of aluminum- and sulfur-bearing free-cutting steel,” J. Iron Steel Res. Int. 22 (S1), 87–92 (2015). https://doi.org/10.1016/s1006-706x(15)30144-8

P. Zhang, Z. Zeng, T. Fan, P. Shen, and J. Fu, “Deep analysis of free-cutting phase and its distribution in japanese SF20T pen tip steel,” IOP Conf. Ser.: Mater. Sci. Eng. 611, 012019 (2019). https://doi.org/10.1088/1757-899x/611/1/012019

D. Wu and Z. Li, “A new Pb-free machinable austenitic stainless steel,” J. Iron Steel Res. Int. 17, 59–63 (2010). https://doi.org/10.1016/s1006-706x(10)60046-5

H. T. Liu and W. Q. Chen, “Hot ductility of eco-friendly low carbon resulphurised free cutting steel with bismuth,” Ironmaking Steelmaking 41, 19–25 (2014). https://doi.org/10.1179/1743281212y.0000000095

H. Yaguchi, “Effect of soft additives (Pb/Bi) on machinability of low carbon resulphurised free machining steels,” Mater. Sci. Technol. 5, 255–267 (1989). https://doi.org/10.1179/mst.1989.5.3.255

H. T. Liu and W. Q. Chen, “Research on recovery for adding low melting point metal bismuth to eco-friendly Bi–S based free cutting steel,” Ironmaking Steelmaking 41, 355–359 (2014). https://doi.org/10.1179/1743281213y.0000000160

H. Fu, J. Rydel, A. Gola, F. Yu, K. Geng, C. Lau, H. Luo, and P. Rivera-Díaz-Del-Castillo, “The relationship between 100Cr6 steelmaking, inclusion microstructure and rolling contact fatigue performance,” Int. J. Fatigue 129, 104899 (2018). https://doi.org/10.1016/j.ijfatigue.2018.11.011

M. Wu, W. Fang, R. Chen, B. Jiang, H. Wang, Ya. Liu, and H. Liang, “Mechanical anisotropy and local ductility in transverse tensile deformation in hot rolled steels: The role of MnS inclusions,” Mater. Sci. Eng.: A 744, 324–334 (2018). https://doi.org/10.1016/j.msea.2018.12.026

A. L. V. da Costa e Silva, “The effects of non-metallic inclusions on properties relevant to the performance of steel in structural and mechanical applications,” J. Mater. Res. Technol. 8, 2408–2422 (2019). https://doi.org/10.1016/j.jmrt.2019.01.009

K. Huang, K. Marthinsen, Q. Zhao, and R. Logé, “The double-edge effect of second-phase particles on the recrystallization behaviour and associated mechanical properties of metallic materials,” Prog. Mater. Sci. 92, 284–359 (2018). https://doi.org/10.1016/j.pmatsci.2017.10.004

K. Hajizadeh and K. J. Kurzydlowski, “Microstructure evolution and mechanical properties of AISI 316H austenitic stainless steel processed by warm multi-pass ecap,” Phys. Met. Metallogr. 122, 931–938 (2021). https://doi.org/10.1134/s0031918x21300013

A. E. Svirid, V. G. Pushin, N. N. Kuranova, V. V. Makarov, and A. N. Uksusnikov, “The effect of heat treatment on the structure and mechanical properties of nanocrystalline Cu–14Al–3Ni alloy subjected to high-pressure torsion,” Phys. Met. Metallogr. 122, 883–890 (2021). https://doi.org/10.1134/s0031918x21090131

V. E. Porsev, A. L. Ul’yanov, and G. A. Dorofeev, “Short-range order evolution in nanocrystalline mechanically activated Fe–Cr alloys in the process of annealing,” Phys. Met. Metallogr. 121, 783–790 (2020). https://doi.org/10.1134/s0031918x20080086

A. N. Lubnin, G. A. Dorofeev, and V. I. Lad’yanov, “X-ray diffraction study of deformational evolution of stacking faults in nanocrystalline metals,” Phys. Met. Metallogr. 121, 1087–1096 (2020). https://doi.org/10.1134/s0031918x2011006x

R. Wu, Q. Yin, J. Wang, Q. Mao, X. Zhang, and Z. Wen, “Effect of Re on mechanical properties of single crystal Ni-based superalloys: Insights from first-principle and molecular dynamics,” J. Alloys Compd. 862, 158643 (2021). https://doi.org/10.1016/j.jallcom.2021.158643

Ye. Jiao, W. Dan, and W. Zhang, “Effects of hydrogen on the deformation mechanism of face-centred cubic Fe–C single crystal with nanovoid: A molecular dynamics simulation,” J. Alloys Compd. 870, 159330 (2021). https://doi.org/10.1016/j.jallcom.2021.159330

Yu. Qi, T. He, H. Xu, Ya. Hu, M. Wang, and M. Feng, “Effects of microstructure and temperature on the mechanical properties of nanocrystalline CoCrFeMnNi high entropy alloy under nanoscratching using molecular dynamics simulation,” J. Alloys Compd. 871, 159516 (2021). https://doi.org/10.1016/j.jallcom.2021.159516

J. Cho and C. T. Sun, “A molecular dynamics simulation study of inclusion size effect on polymeric nanocomposites,” Comput. Mater. Sci. 41, 54–62 (2007). https://doi.org/10.1016/j.commatsci.2007.03.001

A. Rajput and S. K. Paul, “Effect of soft and hard inclusions in tensile deformation and damage mechanism of Aluminum: A molecular dynamics study,” J. Alloys Compd. 869, 159213 (2021). https://doi.org/10.1016/j.jallcom.2021.159213

Yi. Wang, F. Wang, W. Yu, Yu. Wang, and Z. Qi, “Effects of MnS inclusions on mechanical behavior and damage mechanism of free-cutting steel: A molecular dynamics study,” J. Mol. Graphics Modell. 118, 108354 (2022). https://doi.org/10.1016/j.jmgm.2022.108354

M. Wang, F. Wang, J. Zhang, H. Wang, Yi. Wang, and H. Wu, “Effects of h-BN additives on tensile mechanical behavior of Fe matrix: A molecular dynamics study,” Comput. Mater. Sci. 223, 112136 (2023). https://doi.org/10.1016/j.commatsci.2023.112136

J. B. Jeon, B.-J. Lee, and Yo. W. Chang, “Molecular dynamics simulation study of the effect of grain size on the deformation behavior of nanocrystalline body-centered cubic iron,” Scr. Mater. 64, 494–497 (2011). https://doi.org/10.1016/j.scriptamat.2010.11.019

R. Junqiang, Ya. Dan, W. Qi, L. Xuefeng, Z. Xudong, X. Hongtao, T. Fuling, and D. Yutian, “Effect of grain size and twin boundary spacing on plastic deformation of nano-polycrystalline Al alloy by molecular dynamics study,” Rare Met. Mater. Eng. 51, 2436–2445 (2022).

X. Tian, D. Li, Yo. Yu, Z. J. You, T. Li, and L. Ge, “Atomistic simulation study of deformation twinning of nanocrystalline body-centered cubic Mo,” Mater. Sci. Eng., A 690, 277–282 (2017). https://doi.org/10.1016/j.msea.2017.02.105

M. I. Mendelev, S. Han, D. J. Srolovitz, G. J. Ackland, D. Y. Sun, and M. Asta, “Development of new interatomic potentials appropriate for crystalline and liquid iron,” Philos. Mag. 83, 3977–3994 (2003). https://doi.org/10.1080/14786430310001613264

H. Zhou, D. E. Dickel, M. I. Baskes, S. Mun, and M. Asle Zaeem, “A modified embedded-atom method interatomic potential for bismuth,” Modell. Simul. Mater. Sci. Eng. 29, 065008 (2021). https://doi.org/10.1088/1361-651x/ac095c

M. I. Baskes, “Modified embedded-atom potentials for cubic materials and impurities,” Phys. Rev. B 46, 2727–2742 (1992). https://doi.org/10.1103/physrevb.46.2727

V. P. Filippova, S. A. Kunavin, and M. S. Pugachev, “Calculation of the parameters of the Lennard-Jones potential for pairs of identical atoms based on the properties of solid substances,” Inorg. Mater.: Appl. Res. 6, 1–4 (2015). https://doi.org/10.1134/s2075113315010062

A. Arkundato, Z. Su’ud, M. Abdullah, and W. Sutrisno, “Molecular dynamic simulation on iron corrosion-reduction in high temperature molten lead-bismuth eutectic,” Turk. J. Phys. 37, 132–144 (2013). https://doi.org/10.3906/fiz-1112-12

B. Xue, D. B. Harwood, J. L. Chen, and J. I. Siepmann, “Monte Carlo simulations of fluid phase equilibria and interfacial properties for water/alkane mixtures: An assessment of nonpolarizable water models and of departures from the Lorentz–Berthelot combining rules,” J. Chem. Eng. Data 63, 4256–4268 (2018). https://doi.org/10.1021/acs.jced.8b00757

Yu. Wang, F. Wang, W. Yu, Yi. Wang, Z. Qi, and Yi. Wang, “Effects of pressure on volatilisation of pure Bi nanoparticles and Bi–Fe core–shell nanoparticles during continuous heating: a molecular dynamics study,” Mol. Phys. 120 (2022). https://doi.org/10.1080/00268976.2022.2121232

H. Van Swygenhoven, A. Caro, and D. Farkas, “Grain boundary structure and its influence on plastic deformation of polycrystalline FCC metals at the nanoscale: A molecular dynamics study,” Scr. Mater. 44, 1513–1516 (2001). https://doi.org/10.1016/s1359-6462(01)00717-5

P. Hirel, “Atomsk: A tool for manipulating and converting atomic data files,” Comput. Phys. Commun. 197, 212–219 (2015). https://doi.org/10.1016/j.cpc.2015.07.012

S. Melchionna, G. Ciccotti, and B. Lee Holian, “Hoover NPT dynamics for systems varying in shape and size,” Mol. Phys. 78, 533–544 (1993). https://doi.org/10.1080/00268979300100371

B. Frantzdale, S. J. Plimpton, and M. S. Shephard, “Software components for parallel multiscale simulation: an example with LAMMPS,” Eng. Comput. 26, 205–211 (2010). https://doi.org/10.1007/s00366-009-0156-z

A. Stukowski, “Visualization and analysis of atomistic simulation data with OVITO–The open visualization tool,” Modell. Simul. Mater. Sci. Eng. 18, 015012 (2010). https://doi.org/10.1088/0965-0393/18/1/015012

F. C. Frank, “LXXXIII. Crystal dislocations.—Elementary concepts and definitions,” London, Edinburgh, Dublin Philos. Mag. J. Sci. 42, 809–819 (1951). https://doi.org/10.1080/14786445108561310

Funding

This work was supported by the Key Research and Development Projects of Shaanxi Province Project of Shaanxi Province, China (grant no. 2022GY-399).

Author information

Authors and Affiliations

Contributions

J.C. Zhang, M.G. Wang, and H.B. Wang, and are involved in the simulation, calculation, verification, and writing the paper work; Z. Chen visualized the post-processing; F.Z. Wang guided the writing; X.Y. Wang supervised the funding support.

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jingcheng Zhang, Wang, F., Wang, M. et al. Effects of Bi Inclusion on Tensile Mechanical Property and Deformation Mechanism of Nanopolycrystalline Fe: A Molecular Dynamics study. Phys. Metals Metallogr. 124, 1632–1643 (2023). https://doi.org/10.1134/S0031918X23601932

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X23601932