Abstract

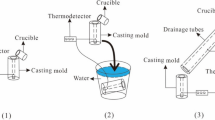

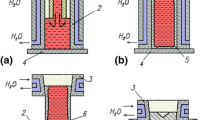

In this study, an experimental device was designed to conduct melt quenching of Al–18Si alloy. The effect of annealing treatment on microstructure and mechanical properties of Al–18Si alloy cast by melt quenching was studied. The results showed that the microstructure of Al–18Si alloy cast by melt quenching was transformed into a pseudo-eutectic microstructure. With the increasing annealing temperature, the dissolution and diffusion rates of the eutectic silicon phase increased, and with the extension of holding time, eutectic silicon tended to spherulite. The best spherulite microstructure was obtained by annealing the alloy at 580°C or 40 min, and the silicon phase surface shape factor (φ) in the microstructure was 0.8. After annealing at 580°C for 40 min, the maximum impact toughness (σb) and elongation (δ) of Al–18Si alloy cast by melt quenching was 99.0 J/cm2 and 13.6%, respectively. Compared with the unannealed Al–18Si alloy cast by melt quenching, the impact toughness and elongation of the annealed alloy increased by 239.0 and 112.5%, respectively.

Similar content being viewed by others

REFERENCES

L. Zhang, S. Chen, Q. Li, and G. Chang, “Formation mechanism and conditions of fine primary silicon being uniformly distributed on single αAl matrix in Al–Si alloys,” Mater. Des. 193, 108853 (2020). https://doi.org/10.1016/j.matdes.2020.108853

Q. Zheng, L. Zhang, H. Jiang, J. Zhao, and J. He, “Effect mechanisms of micro-alloying element La on microstructure and mechanical properties of hypoeutectic Al–Si alloys,” J. Mater. Sci. Technol. 47, 142–151 (2020). https://doi.org/10.1016/j.jmst.2019.12.021

H. S. Wang, Y. Zhang, and D. Q. Yi, “Study on complex heterogeneous nucleation of primary silicon in hypereutectic Al–Si alloy,” China Foundry 67, 344–348 (2018).

R. Haghayeghi and G. Timelli, “An investigation on primary Si refinement by Sr and Sb additions in a hypereutectic Al–Si alloy,” Mater. Lett. 283, 128779 (2021). https://doi.org/10.1016/j.matlet.2020.128779

X. S. Gao, Y. C. Guo, and Z. J. Ma, “Microstructure and properties of multi-Al–Si casting alloy with cooling rate,” Rare Met. 44, 394–400 (2020).

Q. Li, T. Xia, Ye. Lan, W. Zhao, L. Fan, and P. Li, “Effect of rare earth cerium addition on the microstructure and tensile properties of hypereutectic Al–20%Si alloy,” J. Alloys Compd. 562, 25–32 (2013). https://doi.org/10.1016/j.jallcom.2013.02.016

T. Gu, Ye. Pan, T. Lu, C. Li, and J. Pi, “Effects of boron addition on the morphology of silicon phases in Al–Si casting alloys,” Mater. Charact. 141, 115–119 (2018). https://doi.org/10.1016/j.matchar.2018.04.050

G. Mao, S. Liu, Z. Wu, C. Zhu, and W. Gao, “The effects of Y on primary α-Al and precipitation of hypoeutectic Al–Si alloy,” Mater. Lett. 271, 127795 (2020). https://doi.org/10.1016/j.matlet.2020.127795

Q. Zheng, L. Zhang, H. Jiang, J. Zhao, and J. He, “Effect mechanisms of micro-alloying element La on microstructure and mechanical properties of hypoeutectic Al–Si alloys,” J. Mater. Sci. Technol. 47, 142–151 (2020). https://doi.org/10.1016/j.jmst.2019.12.021

M. Zuo, D. Zhao, X. Teng, H. Geng, and Z. Zhang, “Effect of P and Sr complex modification on Si phase in hypereutectic Al–30Si alloys,” Mater. Des. 47, 857–864 (2013). https://doi.org/10.1016/j.matdes.2012.12.054

X. Wu, H. Zhang, H. Jiang, Z. Mi, and H. Zhang, “Multi-refinement effect of rare earth lanthanum on α‑Al and eutectic Si phase in hypoeutectic Al-7Si alloy,” Metals 10, 621 (2020). https://doi.org/10.3390/met10050621

S. Wang, M. Fu, X. Li, J. Wang, and X. Su, “Microstructure and mechanical properties of Al–Si eutectic alloy modified with Al–3P master alloy,” J. Mater. Process. Technol. 255, 105–109 (2018). https://doi.org/10.1016/j.jmatprotec.2017.12.008

L. D. Wang, D. Y. Zhu, and Y. L. Chen, “Effects of melt thermal treatment and modification on solidification microstructure of Al–20%Si alloy,” Chin. J. Nonferrous Met. 21, 2075–2083 (2011). https://doi.org/10.19476/j.ysxb.1004.0609.2011.09.008

Z. Y. Zhu, H. Tu, and C. J. Wu, “Effect of melting and casting process on size and distribution of insoluble phase in aluminium alloy 2618,” Mater. Rep. 35, 4129 (2021).

H. K. Feng, S. R. Yu, Y. L. Li, and L. Y. Gong, “Effect of ultrasonic treatment on microstructures of hypereutectic Al–Si alloy,” J. Mater. Process. Technol. 208, 330–335 (2008). https://doi.org/10.1016/j.jmatprotec.2007.12.121

Z. Cai, C. Zhang, R. Wang, C. Peng, K. Qiu, and N. Wang, “Effect of solidification rate on the coarsening behavior of precipitate in rapidly solidified Al–Si alloy,” Prog. Nat. Sci.: Mater. Int. 26, 391–397 (2016). https://doi.org/10.1016/j.pnsc.2016.08.002

Zh.-K. Zheng, Yo.-J. Ji, W.-M. Mao, R. Yue, and Zh.‑Yo. Liu, “Influence of rheo-diecasting processing parameters on microstructure and mechanical properties of hypereutectic Al–30% Si alloy,” Trans. Nonferrous Met. Soc. China 27, 1264–1272 (2017). https://doi.org/10.1016/s1003-6326(17)60147-x

S. Samat, M. Z. Omar, A. H. Baghdadi, I. F. Mohamed, A. Rajabi, and A. M. Aziz, “Microstructural evolution, dislocation density and tensile properties of Al–6.5Si–2.1Cu–0.35Mg alloy produced by different casting processes,” J. Mater. Sci. Technol. 95, 145–157 (2021). https://doi.org/10.1016/j.jmst.2021.02.074

C. Peeratatsuwan, P. Pandee, U. Patakham, and C. Limmaneevichitr, “Microstructure and rheological properties of a semisolid A356 alloy with erbium addition,” J. Rare Earths 40, 1148–1155 (2021). https://doi.org/10.1016/j.jre.2021.06.011

G. Ma, L. Li, S. Xi, Yi. Xiao, Yo. Li, Z. Yuan, Yu. He, R. Zhou, and Ye. Jiang, “Enhanced combination of strength and ductility in the semi-solid rheocast hypereutectic Al–Si alloy with the effect of in-situ TiB2 particles,” Mater. Charact. 176, 111143 (2021). https://doi.org/10.1016/j.matchar.2021.111143

M. Liu, R. Zheng, W. Xiao, J. Li, G. Li, Q. Peng, and C. Ma, “Bulk nanostructured Al–Si alloy with remarkable improvement in strength and ductility,” Scr. Mater. 201, 113970 (2021). https://doi.org/10.1016/j.scriptamat.2021.113970

J. Wang, J. Zhu, Ya. Liu, H. Peng, and X. Su, “Effect of spheroidization of eutectic Si on mechanical properties of eutectic Al–Si alloys,” J. Mater. Res. 33, 1773–1781 (2018). https://doi.org/10.1557/jmr.2018.144

A. Q. Wang, J. P. Xie, and W. Y. Wang, “Aging precipitation behavior of rapidly solidified Al–21Si–0.8Mg–1.5Cu alloy,” Trans. Mater. Heat. Treat. 34, 86–89 (2013). https://doi.org/10.13289/j.issn.1009-6264.2013.01.013

M. A. A. Hanim, S. C. Chung, and O. K. Chuan, “Effect of a two-step solution heat treatment on the microstructure and mechanical properties of 332 aluminum silicon cast alloy,” Mater. Des. 32, 2334–2338 (2011). https://doi.org/10.1016/j.matdes.2010.12.040

H Z, Y, and C. J. Wu, “Study on solidification structure of melt deeply undercooled hypereutectic Al–Si alloy,” Mater. Rev. 37, 184–189 (2022).

J. Q. Zhu, Y. Liu, and H. P. Peng, “Spheroidization of Si in Al–12.6 wt % Si at eutectic temperature and its tensile properties,” Mater. Res. Express 4, 106505 (2017). https://doi.org/10.1088/2053-1591/aa8d4d

Funding

This project was supported by the National Natural Science Foundation of China (no. 52071032) and Postgraduate Research and Practice Innovation Program of Jiangsu Province (KYCX22_3029).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y.F., Zhou, H., Wang, J.H. et al. Effect of Annealing on Microstructure and Mechanical Properties of Al–18Si Alloy Cast by Melt Quenching. Phys. Metals Metallogr. 124, 1856–1865 (2023). https://doi.org/10.1134/S0031918X23600884

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X23600884