Abstract

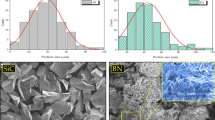

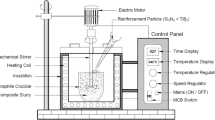

Effect of hybridization on the rate-dependent behaviour of Aluminum metal matrix composites (MMCs) comprising (0, 10, 20, and 30%) monolithic and hybrid SiC–B4C were prepared by powder metallurgy technique and tested under quasi-static and dynamic compression. Split Hopkinson pressure bar results revealed diverse strain rates attained by MMCs. 30% SiC reinforcement of Al matrix resulted in 16.9% higher stress and 13.5% higher toughness compared to 30% B4C reinforced MMC. Hybridizing 20% SiC–10% B4C with Al-matrix resulted in 18.9% higher stress and 29.7% higher toughness compared to 30% B4C reinforced MMC. Damage studies revealed how inverting hybrid particle reinforcement leads to improved mechanical performance.

Similar content being viewed by others

REFERENCES

S. Ghanaraja, K. L. V. Kumar, H. P. Raju, and K. S. Ravikumar, “Processing and mechanical properties of hot extruded Al(Mg)–Al2O3 composites,” Mater. Today: Proc. 2, 1291–1300 (2015). https://doi.org/10.1016/j.matpr.2015.07.045

D. Patidar and R. S. Rana, “Effect of B4C particle reinforcement on the various properties of aluminium matrix composites: A survey paper,” Mater. Today: Proc. 4, 2981–2988 (2017). https://doi.org/10.1016/j.matpr.2017.02.180

B. V. Ramnath, C. Elanchezhian, R. Annamalai, S. Aravind, T. S. A. Atreya, V. Vignesh, and C. Subramanian, “Aluminium metal matrix composites-A review,” Rev. Adv. Mater. Sci. 38, 55–60 (2014).

A. Sharma, V. M. Sharma, S. Mewar, S. K. Pal, and J. Paul, “Friction stir processing of Al6061–SiC-graphite hybrid surface composites,” Mater. Manuf. Processes 33, 795–804 (2018). https://doi.org/10.1080/10426914.2017.1401726

Ş. Karabulut, U. Gökmen, and H. Çinici, “Study on the mechanical and drilling properties of AA7039 composites reinforced with Al2O3/B4C/SiC particles,” Compos. Part B: Eng. 93, 43–55 (2016). https://doi.org/10.1016/j.compositesb.2016.02.054

P. Singh, N. R. Chauhan, and S. Rajesha, “Effect of the addition of ductile phase on mechanical properties of alumina/nano SiC ceramic composite,” Adv. Mater. Process. Technol. (2022). https://doi.org/10.1080/2374068x.2022.2120291

M. R. Allazadeh, M. K. Itani, and S. N. Wosu, “Compression of the material characteristics of steel, aluminum, wood and woven graphite epoxy composites in response to high strain rate load,” Adv. Mater. Sci. Appl. 1, 13–30 (2012). https://doi.org/10.5963/amsa0101003

S. Prasad, H. Chouhan, K. Kartikeya, K. K. Singh, and N. Bhatnagar, “An experimental investigation into mechanical behaviour of Basalt PEI laminates at various strain rates,” Compos. Struct. 267, 113800 (2021). https://doi.org/10.1016/j.compstruct.2021.113800

T. V. Knyazyuk, A. A. Zisman, N. S. Novoskol’tsev, and E. I. Khlusova, “Anomalous refinement of the austenite grain upon high-strain-rate hot deformation of microalloyed medium-carbon steel,” Phys. Met. Metallogr. 121, 543–547 (2020). https://doi.org/10.1134/s0031918x20060095

Yo. Suo, Z. Deng, B. Wang, Ya. Gong, and P. Jia, “Constitutive model of metal matrix composites at high strain rates and its application,” Mater. Today Commun. 27, 102328 (2021). https://doi.org/10.1016/j.mtcomm.2021.102328

C. San Marchi, F. Cao, M. Kouzeli, and A. Mortensen, “Quasistatic and dynamic compression of aluminum-oxide particle reinforced pure aluminum,” Mater. Sci. Eng., A 337, 202–211 (2002). https://doi.org/10.1016/S0921-5093(02)00035-7

H. Zhang, K. T. Ramesh, and E. S. C. Chin, “High strain rate response of aluminum 6092/B4C composites,” Mater. Sci. Eng., A 384, 26–34 (2004). https://doi.org/10.1016/j.msea.2004.05.027

B. Liu, W. Huang, H. Wang, M. Wang, and X. Li, “Compressive behavior of high particle content B4C/Al composite at elevated temperature,” Trans. Nonferrous Met. Soc. China 23, 2826–2832 (2013). https://doi.org/10.1016/s1003-6326(13)62803-4

J. Zhang, H. Shi, M. Cai, L. Liu, and P. Zhai, “The dynamic properties of SiCp/Al composites fabricated by spark plasma sintering with powders prepared by mechanical alloying process,” Mater. Sci. Eng., A 527, 218–224 (2009). https://doi.org/10.1016/j.msea.2009.08.067

Z. H. Tan, B. J. Pang, D. T. Qin, J. Y. Shi, and B. Z. Gai, “The compressive properties of 2024Al matrix composites reinforced with high content SiC particles at various strain rates,” Mater. Sci. Eng., A 489, 302–309 (2008). https://doi.org/10.1016/j.msea.2007.12.021

H. Lee, S. S. Sohn, C. Jeon, I. Jo, S.-K. Lee, and S. Lee, “Dynamic compressive deformation behavior of SiC-particulate-reinforced A356 Al alloy matrix composites fabricated by liquid pressing process,” Mater. Sci. Eng., A 680, 368–377 (2017). https://doi.org/10.1016/j.msea.2016.10.102

A. N. Petrova, I. G. Brodova, S. V. Razorenov, E. V. Shorokhov, and T. K. Akopyan, “Mechanical properties of the Al–Zn–Mg–Fe–Ni alloy of eutectic type at different strain rates,” Phys. Met. Metallogr. 120, 1221–1227 (2019). https://doi.org/10.1134/s0031918x19120135

A. K. Bodukuri, K. Eswaraiah, K. Rajendar, and V. Sampath, “Fabrication of Al–SiC–B4C metal matrix composite by powder metallurgy technique and evaluating mechanical properties,” Perspect. Sci. 8, 428–431 (2016). https://doi.org/10.1016/j.pisc.2016.04.096

S. Krishnakumar and T. Senthilvelan, “Experimental analysis on the flow properties of Al–B4C, Al–TiO2 composites produced by P/M process,” Mater. Today: Proc. 5, 11585–11592 (2018). https://doi.org/10.1016/j.matpr.2018.02.127

D. Bommana, T. R. K. Dora, N. P. Senapati, and A. S. Kumar, “Effect of 6 wt % particle (B4C + SiC) reinforcement on mechanical properties of AA6061 aluminum hybrid MMC,” Silicon 14, 4197–4206 (2022). https://doi.org/10.1007/s12633-021-01210-4

B. A. Gama, S. L. Lopatnikov, and J. W. J. Gillespie, “Hopkinson bar experimental technique: A critical review,” Appl. Mech. Rev. 57, 223–250 (2014). https://doi.org/10.1115/1.1704626

H. Chouhan, N. A. Bhalla, and N. Bhatnagar, “High strain rate performance of UHMWPE composites: Effect of moisture ingress and egress,” Mater. Today Commun. 26, 101709 (2021). https://doi.org/10.1016/j.mtcomm.2020.101709

H. Chouhan, N. A. Bhalla, A. K. Bandaru, S. A. Gebremeskel, and N. Bhatnagar, “Quasi-static and high strain rate response of Kevlar reinforced thermoplastics,” Polym. Test. 93, 106964 (2021). https://doi.org/10.1016/j.polymertesting.2020.106964

A. K. Bandaru, H. Chouhan, S. Prasad, P. M. Weaver, N. Bhatnagar, and R. O’Higgins, “Effect of weave pattern on high strain rate performance of glass polytetrafluoroethylene composites,” Polym. Compos. 43, 1809–1822 (2021). https://doi.org/10.1002/pc.26499

N. K. Naik, P. J. Shankar, V. R. Kavala, G. Ravikumar, J. R. Pothnis, and H. Arya, “High strain rate mechanical behavior of epoxy under compressive loading: Experimental and modeling studies,” Mater. Sci. Eng., A 528, 846–854 (2011). https://doi.org/10.1016/j.msea.2010.10.099

D. Lehmhus, J. Weise, J. Baumeister, L. Peroni, M. Scapin, C. Fichera, M. Avalle, and M. Busse, “Quasi-static and dynamic mechanical performance of glass microsphere- and cenosphere-based 316L syntactic foams,” Procedia Mater. Sci. 4, 383–387 (2014). https://doi.org/10.1016/j.mspro.2014.07.578

D. J. Lloyd, “Particle reinforced aluminium and magnesium matrix composites,” Int. Mater. Rev. 39, 1–23 (1994). https://doi.org/10.1179/imr.1994.39.1.1

A. G. Evans, J. W. Hutchinson, and R. M. Mcmeeking, “Stress-strain behavior of metal matrix composites with discontinuous reinforcements,” Scr. Metall. Mater. 25, 3–8 (1991). https://doi.org/10.1016/0956-716x(91)90344-z

ACKNOWLEDGMENTS

Authors are grateful to Prof. Naresh Bhatnagar, Production Engineering Lab., Mechanical Engineering Department, IIT Delhi for granting permission to conduct the experiments.

Funding

This work was supported by ongoing institutional funding. No additional grants to carry out or direct this particular research were obtained.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tulsi Chouhan, Manoj Soni Rate-Dependent Compressive Behaviour of SiC−B4C−Al Hybrid Composites. Phys. Metals Metallogr. 124, 1567–1578 (2023). https://doi.org/10.1134/S0031918X22601688

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X22601688