Abstract

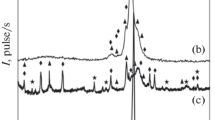

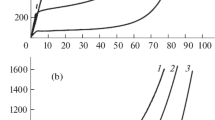

The tensile tests in combination with the electron microscopy and X-ray technique have provided data on the mechanical properties of the ultrafine-grained (UFG) shape-memory Cu–14 wt % Al–3 wt % Ni alloy at different temperatures and its fracture character. The UFG structure in the alloy has formed during severe plastic deformation performed by high pressure torsion. The study has shown two variants of the mechanical behavior of the UFG alloy depending on the temperature and strain rate during mechanical testing. The first case is the deformation of the alloy in the martensitic state at moderate test temperatures (300, 423, 473 K). This stage is characterized by a high hardening coefficient and moderate uniform relative elongation and reduction. The second case is deformation at higher test temperatures (573, 673 K). It is characterized mainly by large uniform localized plastic deformation and moderate hardening due to dynamic recrystallization.

Similar content being viewed by others

REFERENCES

J. Perkins, Shape Memory Effects in Alloys (Plenum, London, 1975).

Kh. Varlimont and L. Dilei, Martensite Transformations in Alloys Based on Copper, Silver, and Gold (Nauka, Moscow, 1980) [in Russian].

K. Ootsuka, K. Simidzu, Yu. Sudzuki, Yu. Sekiguti, Ts. Tadaki, T. Khomma, and S. Miyadzaki, Shape Memory Alloys (Metallurgiya, Moscow, 1990) [in Russian].

Engineering Aspects of Shape Memory Alloy, Ed. by T. W. Duering, K. L. Melton, D. Stockel, and C. M. Wayman, (Butterworth-Heineman, London, 1990).

V. N. Khachin, V. G. Pushin, and V. V. Kondrat’ev, Titanium Nickelide: Structure and Properties (Nauka, Moscow, 1992).

V. G. Pushin, V. V. Kondrat’ev, and V. N. Khachin, Pre-transitional Phenomena and Martensitic Transformations (UrO RAN, Yekaterinburg, 1998) [in Russian].

E. Bonnot, R. Romero, L. Mañosa, E. Vives, and A. Planes, “Elastocaloric effect associated with the martensitic transition in shape-memory alloys,” Phys. Rev. Lett. 100, 125901 (2008).

J. Cui, Y. Wu, J. Muehlbauer, Y. Hwang, R. Radermacher, S. Fackler, M. Wuttig, and I. Takeuchi, “Demonstration of high efficiency elastocaloric cooling with large δT using NiTi wires,” Appl. Phys. Lett. 101, 073904 (2012).

L. Mañosa, S. Jarque-Farnos, E. Vives, and A. Planes, “Large temperature span and giant refrigerant capacity in elastocaloric Cu–Zn–Al shape memory alloys,” Appl. Phys. Lett. 103, 211904 (2013).

P. Sedlak, H. Seiner, M. Landa, V. Novák, P. Šittner, and L. I. Manosa, “Elastic Constants of bcc Austenite and 2H orthorhombic martensite in CuAlNi shape memory alloy,” Acta Mater. 53, 3643–3661 (2005).

R. Dasgupta, “A look into Cu–based shape memory alloys: Present Scenario and future prospects,” J. Mater. Res. 29, No. 16, 1681–1698 (2014).

V. Pushin, N. Kuranova, E. Marchenkova, and A. Pushin, “Design and development of Ti–Ni, Ni–Mn–Ga and Cu–Al–Ni-based alloys with high and low temperature shape memory effects,” Materials 12, 2616–2640 (2019).

A. V. Lukyanov, V. G. Pushin, N. N. Kuranova, A. E. Svirid, A. N. Uksusnikov, Yu. M. Ustyugov, and D. V. Gunderov, “Effect of the thermomechanical treatment on structural and phase transformations in Cu–14Al–3Ni shape memory alloy subjected to high-pressure torsion,” Phys. Met. Metallogr. 119, 374–382 (2018).

A. E. Svirid, A. V. Luk’yanov, V. G. Pushin, E. S. Belo-sludtseva, N. N. Kuranova, and A. V. Pushin, “Effect of the temperature of isothermal upsetting on the structure and the properties of the shape memory Cu–14 wt % Al–4 wt % Ni alloy,” Phys. Met. Metallogr. 120, 1159–1165 (2019).

A. E. Svirid, V. G. Pushin, N. N. Kuranova, E. S. Belo-sludtseva, A. V. Pushin, and A. V. Lukyanov, “The effect of plastification of Cu–14Al–4Ni alloy with the shape memory effect in high-temperature isothermal precipitation,” Tech. Phys. Lett. 46, 118–121 (2020).

A. E. Svirid, V. G. Pushin, N. N. Kuranova, V. V. Makarov, A. V. Pushin, A. N. Uksusnikov, and A. V. Luk’yanov, “Application of isothermal upset for megaplastic deformation of Cu–Al–Ni β alloys,” Tech. Phys. 90, 1044–1055 (2020).

A. E. Svirid, V. G. Pushin, N. N. Kuranova, V. V. Makarov, and A. N. Uksusnikov, “The effect of heat treatment on the structure and mechanical properties of nanocrystalline Cu–14Al–3Ni alloy subjected to high-pressure torsion,” Phys. Met. Metallogr. 122, No. 9, 883–890 (2021).

A. Pelosin and A. Riviere, “Structural and mechanical spectroscopy study of the \(\beta _{1}^{'}\) martensite decomposition in Cu–12% Al–3% Ni (wt %) alloy,” J. Alloys Compd. 268, 166–172 (1998).

F. Dagdelen, T. Gokhan, A. Aydogdu, Y. Aydogdu, and O. Adiguzel, “Effect of thermal treatments on transformation behavior in shape memory Cu–Al–Ni alloys,” Mater. Lett. 57, 1079–1085 (2003).

Z. Li, Z. Y. Pan, N. Tang, Y. B. Jiang, N. Liu, M. Fang, and F. Zheng, “Cu–Al–Ni–Mn shape memory alloy processed by mechanical alloying and powder metallurgy,” Mater. Sci. Eng., A 417, 225–229 (2006).

N. Suresh and U. Ramamurty, “Aging response and its effect on the functional properties of Cu–Al–Ni shape memory alloys,” J. Alloys Compd. 449, 113–118 (2008).

R. D. Dar, H. Yan, and Y. Chen, “Grain boundary engineering of Co–Ni–Al, Cu–Zn–Al, and Cu–Al–Ni shape memory alloys by intergranular precipitation of a ductile solid solution phase,” Scr. Mater. 115, 113–117 (2016).

P. La Roca, L. Isola, Ph. Vermaut, and J. Malarria, “Relationship between grain size and thermal hysteresis of martensitic transformations in Cu-based shape memory alloys,” Scr. Mater. 135, 5–9 (2017).

X. Zhang, X. Zhao, F. Wang, L. Qingsuo, and Q. Wang, “Microstructure, mechanical properties and shape memory effect of Cu–Hf–Al–Ni alloys,” Mater. Sci. Technol. 34, No. 12, 1497–1501 (2018).

A. E. Svirid, V. G. Pushin, N. N. Kuranova, A. V. Luk’yanov, A. V. Pushin, A. N. Uksusnikov, and Y. M. Ustyugov, “The structure–phase transformations and mechanical properties of the shape memory effect alloys based on the system Cu–Al–Ni,” Mater. Today: Proc. 4, 4758–4762 (2017).

A. E. Svirid, N. N. Kuranova, A. V. Luk’yanov, V. V. Makarov, N. V. Nikolaeva, V. G. Pushin, and A. N. Uksusnikov, “Influence of thermomechanical treatment on structural-phase transformations and mechanical properties of the Cu–Al–Ni shape-memory alloys,” Russ. Phys. J. 61, 1681–1686 (2018).

A. E. Svirid, A. V. Luk’yanov, V. V. Makarov, V. G. Pushin, and A. N. Uksusnikov, “Influence of doping with aluminum on the structure, phase transformations and properties of Cu–Al–Ni alloys with shape memory effect,” Chelyabinskii Fiz.-Mat. Zh. 4, 108–117 (2019).

ACKNOWLEDGMENTS

The study was performed at the Center of the Collaborative Access “Test Center of Nanotechnologies and Advanced Materials,” Institute of Metal Physics, Ural Branch, Russian Academy of Sciences.

Funding

This work was performed within the scope of the State Task (theme “Structure,” no. АААА-А18-118020190106-6).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Gapontseva

Rights and permissions

About this article

Cite this article

Svirid, A.E., Pushin, V.G., Kuranova, N.N. et al. Effect of the Temperature of Mechanical Tests on the Properties of the Nanocrystalline Cu–14Al–3Ni Alloy Subjected to High Pressure Torsion. Phys. Metals Metallogr. 123, 50–56 (2022). https://doi.org/10.1134/S0031918X22010136

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X22010136