Abstract

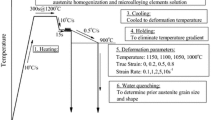

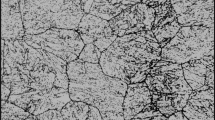

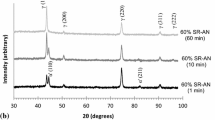

Effect of primary austenite grain size and processing parameters on the critical strain of dynamic recrystallization (DRX) during finishing has been investigated and modeled in the present paper. The stress-strain curves were achieved based on the hot compression experiments in the condition of different temperatures and strain rates with different primary austenite grain size. The deformation temperature and strain rate were normalized as Zener–Hollomon (Z) parameter. The experimental results illustrated that the critical strain for DRX was significantly influenced by the primary austenite grain size but peak strain was not, which has been interpreted based on the nucleation and growth of DRX grains. The modeling parameters have been established based on Sellars’ model, with which the effect of grain size and processing parameters on the critical strain for austenite DRX could be quantitatively calculated, which is helpful to design rolling schedule for promote DRX in order to refine grain size. A seven-passes rolling schedule was designed in the case of only 1.5 reduction ratio. The experimental results confirmed that the grain size was significantly refined by promoting austenite DRX, which are good agreement with modeling calculation.

Similar content being viewed by others

REFERENCES

T. Gladman, B. Holmes, and F. B. Pickering, “Work hardening of lowcarbon steels,” J. Iron Steel Int. 208, 172–183 (1970).

E. El-Shenawy and R. Reda, “Optimization of TMCP strategy for microstructure refinement and flow-productivity characteristics enhancement of low carbon steel,” J. Mater. Res. Technol. 8, 2819–2831 (2019).

P. Gong, E. J. Palmiere, and W. M. Rainforth, “Thermomechanical processing route to achieve ultrafine grains in low carbon microalloyed steels,” Acta Mater. 119, 43–54 (2016).

S. Mandal, N. K. Tewary, S. K. Ghosh, D. Chakrabarti, and S. Chatterjee, “Thermo-mechanically controlled processed ultrahigh strength steel: Microstructure, texture and mechanical properties,” Mater. Sci. Eng., A 663, 126–140 (2016).

C. M. Sellars and J. H. Beynon, “Microstructural development during hot rolling of titanium microalloyed steels,” Proceedings of an international conference on high strength low alloy steels (Australia, 1985), pp. 142–150.

G. H. Zhu and S. V. Subramanian, “Recrystallization behavior design for controlling grain size in strip rolling process,” J. Iron Steel Res. Int. 15, 39–44 (2008).

G. H. Zhu and S. V. Subramanian, “Ultra-fine grain size control and mixed grains elimination in industrial multi-pass rolling processing.,” Mater. Sci. Eng., A 426, 235–239 (2006).

W. Shen, C. Zhang, L. Zhang, Q. Xu, Y. Cui, and Y. Xu, “A modified Avrami equation for kinetics of static recrystallization of Nb–V microalloyed steel: Experiments and numerical simulation,” Vacuum 150, 116–123 (2018).

K. B. Kang, O. Kwon, W. B. Lee, and C. G. Park, “Effect of precipitation on the recrystallization behavior of a Nb containing steel,” Scr. Mater. 36, 1303–1308 (1997).

C. García-Mateo, B. López, and J. M. Rodriguez-Ibabe, “Static recrystallization kinetics in warm worked vanadium microalloyed steels,” Mater. Sci. Eng., A 303, 216–225 (2001).

J. Majta, J. G. Lenard, and M. Pietrzyk, “Modellong the evolution of the microstructure of a Nb steel,” ISIJ Int. 36, 1094–1102 (1996).

J. H. Beynon and C. M. Sellars, “Modelling microstructure and its effects during multipass hot rolling,” ISIJ Int. 32, 359–367 (1992).

C. M. Sellars, “Physical metallurgy of hot working,” in Hot Working and Forming Processes, Ed by C. M. Sellars and G. J. Davies, (Material Society, London, 1980), pp. 3–15.

A. M. Elwazri, P. Wanjara, and S. Yue, “Dynamic recrystallization of austenite in microalloyed high carbon steels,” Mater. Sci. Eng., A 339, 209–215 (2003).

H. J. McQueen and J. J. Jonas, “Recovery and recrystallization in the hot-working of aluminium alloy,” in Plastic Deformation of Materials, Ed. by R. J. Arsenault (Academic Press, New York, 1975), pp. 393–493.

J. Xing, H. Ding, G. Zhu, F. Li, and J. Li, “Physically based modeling of critical strain for dynamic recrystallization,” (Under review).

G. R. Johnson and W. H. Cook, “A constitutive model and data for metals subjected to large strain, high strain rates and high temperatures,” Proceedings of the Seventh International Symposium on Ballistic (Den Haag, 1983).

G. R. Johnson and W. H. Cook, “Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures,” Eng. Fract. Mech. 21, 31–48 (1985).

C. Zener and J. H. Hollomon, “Effect of strain rate upon plastic flow of steel,” J. Appl. Phys. 5, 22–32 (1944).

D. Ponge and G. Gottstein, “Necklace formation during dynamic recrystallization: Mechanisms and impact on flow behavior,” Acta Mater. 46, 69–80 (1998).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Xing, J., Zhu, G.H., Ding, H.L. et al. Effect of Grain Size and Processing Parameters on Critical Strain for Austenite Dynamic Recrystallization. Phys. Metals Metallogr. 123, 1299–1305 (2022). https://doi.org/10.1134/S0031918X21100598

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X21100598