Abstract

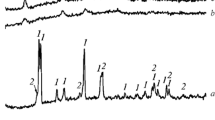

The products of the mechanochemical reduction of iron oxide with aluminum have been studied by means of X-ray diffraction analysis, infrared and Mössbauer spectroscopy. It is shown that the products of the mechanochemical reaction at a stoichiometric ratio of iron oxide and aluminum contain iron, α‑Al2O3, and a large amount of spinel (hercynite), which slightly decreases with an increase in the time of mechanical activation. According to the Mössbauer spectroscopy data, the reduction of iron oxide proceeds faster with a twofold increase in the aluminum content as compared to the stoichiometric one, and the excess aluminum reacts with the reduced iron, forming intermetallic FexAly phases mainly the monoaluminide FeAl strengthened by α-Al2O3 particles. Upon a threefold excess of the aluminum content over the stoichiometric one, the mechanochemical reduction slows down and the amount of FexAly intermetallic compounds with a higher aluminum content increases in the final products of reaction.

Similar content being viewed by others

REFERENCES

A. R. Miedema, P. F. de Chatel, and F. R. de Boer, “Cohesion in alloys–fundamentals, of a semi-empirical model,” Phys. B + C 100, 1–28 (1980).

T. F. Grigor’eva, A. P. Barinova, and N. Z. Lyakhov, “Mechanochemical synthesis of intermetallic compounds,” Russ. Chem. Rev. 70, No. 1, 45–73 (2001).

E. P. Elsukov, G. A. Dorofeev, G. N. Konygin, V. M. Fomin, and A. V. Zagainov, “Comparative analysis of the mechanisms and kinetics of mechanical alloying in the systems Fe(75)X(25); X = C, Si,” Phys. Met. Metallogr. 93, No. 3, 278–288 (2002).

E. P. Elsukov, G. A. Dorofeev, A. L. Ul’yanov, and A. V. Zagainov, “Structural and phase transformations upon mechanical alloying in the Fe(50)Ge(50) system,” Phys. Met. Metgallogr. 95, No. 5, 486–492 (2003).

E. P. Elsukov, A. L. Ul’yanov, V. E. Porsev, D. A. Kolodkin, A. V. Zagainov, and O. M. Nemtsova, “Peculiarities of mechanical alloying of high-concentration Fe–Cr alloys,” Phys. Met. Metallogr. 119, No. 2, 153–160 (2018).

E. Yu. Ivanov, T. F. Grigor’eva, G. V. Golubkova, V. V. Boldyrev, A. B. Fasman, and S. D. Mikhailenko, “Mechanochemical synthesis of nickel aluminides,” Izv. Sib. Otd. Akad. Nauk SSSR, Ser. Khim. 6, 80–83 (1988).

T. F. Grigor’eva, G. V. Golubkova, and E. Yu. Ivanov, “Formation of supersaturated solid solutions during MA of crystalline nickel and aluminum,” Izv. Sib. Otd. Akad. Nauk SSSR, Ser. Khim. 5, 107–110 (1989).

T. F. Grigor’eva, A. P. Barinova, and V. V. Boldyrev, “Influence of the size factor and electron concentration on the degree of supersaturation of copper-based solid solutions obtained by mechanochemical synthesis,” Neorg. Mater. 32, No. 1, 41–43 (1996).

T. A. Sviridova, A. P. Shevchukov, E. V. Shelekhov, and P. A. Borisova, “Use of mechanical alloying and subsequent annealing for obtaining intermetallic compound CuAl2,” Phys. Met. Metallogr. 112, No. 4, 356–370 (2011).

E. G. Volkova, A. Yu. Volkov, and B. D. Antonov, “Structure of Al2Au intermetallic compound obtained by mechanochemical synthesis,” Phys. Met. Metallogr. 119, No. 7, 650–659 (2018).

V. M. Schastlivtsev and V. I. Zel’dovich, “Effect of extreme impacts on the structure and properties of alloys,” Phys. Met. Metallogr. 119, No. 9, 858–861 (2018).

E. V. Voronina, A. K. Al’Saedi, A. G. Ivanova, A. K. Arzhnikov, and E. N. Dulov, “Structural and phase transformations occurring during preparation of ordered ternary Fe–Al–M alloys (M = Ga, B, V, Mn) by mechanical alloying,” Phys. Met. Metallogr. 120, No. 12, 1213–1220 (2019).

N. S. Larionova, R. M. Nikonova, A. L. Ul’yanov, M. I. Mokrushina, and V. I. Lad’yanov, “Deformation-induced structural-phase transformations during mechanosynthesis of Fe-fullerite in toluene,” Phys. Met. Metallogr. 120, No. 9, 858–866 (2019).

L. S. Vasil’ev and S. L. Lomaev, “Influence of pressure on the processes of formation and evolution of the nanostructure in plastically deformed metals and alloys,” Phys. Met. Metallogr. 120, No. 6, 600–606 (2019).

G. B. Schaffer and P. G. McCormic, “Combustion synthesis by mechanical alloying,” Scr. Metall. 23, No. 6, 835–838 (1989).

L. Takacs, “Reduction of magnetite by aluminum: a displacement reaction induced by mechanical alloying,” Mater. Lett. 13, 119–124 (1992).

G. Concas, A. Corrias, E. Manca, G. Morongiu, G. Paschina, and G. Spano, “An X-ray diffraction and Mössbauer spectroscopy study of the reaction between hematite and aluminium activated by ball milling,” Z. Naturforsch, A 53, No. 5, 239–244 (1998).

R. Checchetto, C. Tosello, A. Miotello, and G. Principi, “Structural evolution of Fe–Al multilayer thin films for different annealing temperatures,” J. Phys.: Condens. Matter 13, No. 5, 811–821 (2001).

F. Cardellini, V. Contini, R. Gupta, G. Mazzone, A. Montone, A. Perin, and G. Principi, “Microstructural evolution of Al–Fe powder mixtures during high-energy ball milling,” J. Mater. Sci. 33, No. 10, 2519–2527 (1998).

T. Yu. Kiseleva, T. F. Grigor’eva, D. V. Gostev, V. B. Potapkin, A. N. Falkova, and A. A. Novakova, “Structural study of Fe–Al nanomaterial produced by mechanical activation and self-propagating high-temperature synthesis,” Moscow Univ. Phys. Bull. 63, No. 1, 55–60 (2008).

R. M. Cornell and U. Schwertmann, Iron Oxides: Structure, Properties, Reactions, Occurrences and Uses (Wiley, New York, 2006).

DIFFRAC plus : EVA. Bruker AXS GmbH (Karlsruhe, 2008).

Powder Diffraction File PDF4+ ICDD (2015).

J. Laugier and B. Bochu, LMGP-Suite of Programs for the interpretation of X-ray Experiments (Lab. Materiaux genie Phys., Grenoble, 2003).

H. M. Rietveld, “A profile refinement method for nuclear and magnetic structures,“ J. Appl. Crystallogr. 2, 65–71 (1969).

DIFFRAC plus : TOPAS. Bruker AXS GmbH (Karlsruhe, 2006).

V. A. Podergin, Metallothermal Systems (Metallurgiya, Moscow, 1992) [in Russian].

P. Tarte, “Infra-red spectra of inorganic aluminates and characteristic vibrational frequencies of AlO4 tetrahedra and AlO6 octahedra,” Spectrochimi. Acta, Part A 23, No. 7, 2127–2143 (1967).

G. B. Andreozzi, G. Baldi, G. P. Berbardini, F. Di Benedetto, and M. Romanelli, “57Fe Mössbauer and electronic spectroscopy study on a new synthetic hercynite-based pigment,” J. Eur. Ceram. Soc. 24, No. 5, 821–824 (2004).

Funding

This study was supported by the Belarus Republic Foundation for Basic Research (project no. T20P-037) and the Russian Foundation for Basic Research (project no. 20-53-00037).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Kadkin

Rights and permissions

About this article

Cite this article

Grigoreva, T.F., Kiseleva, T.Y., Petrova, S.A. et al. Mechanochemically Stimulated Reactions of the Reduction of Iron Oxide with Aluminum. Phys. Metals Metallogr. 122, 572–578 (2021). https://doi.org/10.1134/S0031918X2106003X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X2106003X