Abstract

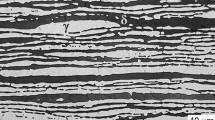

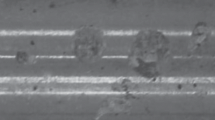

Electron microscopic studies have been performed to investigate carbides, nitrides, and carbonitrides precipitated in chromium-nickel austenitic steels, which have been alloyed with nitrogen, silicon, boron, and rare-earth metals (REM) in different concentrations, and affecting the intergranular corrosion in these steels in highly-oxidizing environments. The intergranular corrosion has been found to result mainly from heating-induced precipitation of chromium carbides or carboborides, such as Cr23(C, B)6, which deplete the border areas of chromium to a greater extent than nitrides. The low corrosion rate corresponds to a lower dislocation number density. Concentrations of boron and REMs that do not have a negative effect on intergranular corrosion have been found.

Similar content being viewed by others

REFERENCES

V. V. Naumenko, Candidate’s Dissertation in Engineering (Moscow, 2012).

R. Robin, F. Miserque, and V. Spagnol, “Correlation between composition of passive layer and corrosion behavior of high Si-containing austenitic stainless steels in nitric acid,” J. Nucl. Mater. 375, No. 1, 65–71 (2008).

B. E. Wilde, “Influence of silicon on the intergranular corrosion behavior of 18Cr–8Ni stainless steels,” Corros. Sci. 44, No. 10, 699–704 (1988).

O. V. Kasparova, “Peculiarities of intergranular corrosion of silicon-containing austenitic stainless steels,” Prot. Met. 40, No. 5, 475–481 (2004).

S. Ningshen, U. K. Mudali, G. Amarendra, and B. Raj, “Corrosion assessment of nitric acid grade austenitic stainless steels,” Corros. Sci. 51, No. 2, 322–329 (2009).

K. Huang and R. E. Logé, “Microstructure and flow stress evolution during hot deformation of 304L austenitic stainless steel in variable thermomechanical conditions,” Mater. Sci. Eng. 711, 600–610 (2018).

M. V. Pridantsev, Influence of Impurities and Rare Earth Elements on the Properties of Alloys (Metallurgizdat, Moscow, 1962) [in Russian].

K. A. Lanskaya, Heat Resistant Steels (Metallurgiya, Moscow, 1969) [in Russian].

Yu. N. Goykhenberg, L. G. Zhuravlev, D. A. Mirzayev, V. V. Zhuravleva, Ye. P. Silina, and V. Yu. Vnukov, “Corrosion cracking, structure and properties of hardened Cr–Mn austenitic steels with nitrogen,” Phys. Met. Metallogr. 65, No. 6, 83–89 (1988).

L. G. Korshunov, Yu. N. Goikhenberg, and N. L. Chernenko, “Influence of silicon on the structure, tribological and mechanical properties of nitrogen-containing Cr–Mn austenitic steels,” Fiz. Met. Metalloved. 96, No. 3, 100–110 (2003).

S. Yu. Mushnikova, S. K. Kostin, V. V. Sagaradze, and N. V. Kataeva, “Structure, properties, and resistance to stress-corrosion cracking of a nitrogen-containing austenitic steel strengthened by thermomechanical treatment,” Phys. Met. Metallogr. 118, No. 11, 1155–1166 (2017).

V. V. Sagaradze, N. V. Kataeva, I. G. Kabanova, S. V. Afanas’ev, and A. V. Pavlenko, “Effect of the temperature of shock-wave loading on structure and phase transformations in nitrogen-containing austenitic Cr–Mn–Ni steel, Phys. Met. Metallogr. 121, No. 7, 683–688 (2020).

Yu. P. Solntsev, B. S. Ermakov, and S. O. Malikov, “Role of Si in the formation of the corrosion resistance of austenitic materials for cryogenic engineering,” Russ. Metall. (Metally). 2, 133–137 (2008).

B. S. Ermakov and Yu. P. Solntsev, “Intergranular corrosion as a major factor in increased destruction of equipment made from austenitic steels,” Baltiiskie Metally, No. 2, 18–21 (2000).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by T. Gapontseva

Rights and permissions

About this article

Cite this article

Maznichevskii, A.N., Goikhenberg, Y.N. & Sprikut, R.V. Electron-Microscopy Investigation of Excess-Phase Precipitates Affecting the Intergranular Corrosion of Chromium–Nickel Austenitic Steels. Phys. Metals Metallogr. 122, 362–369 (2021). https://doi.org/10.1134/S0031918X2103011X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X2103011X