Abstract

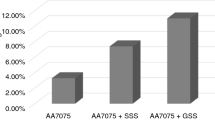

The article deals with the monitoring of the behavior of sodium chloride in interaction with the aluminum alloy melt. Sodium chloride is an excellent substance for the production of expanded aluminum materials. Its melting point is 801°C and an advantageous is that NaCl can be easy applicable from an ecological point of view. The theoretical calculations of melt penetration between sodium chloride grains were performed and the angle of wetting of sodium chloride particles by aluminum melt was determined. Furthermore, it has been confirmed that a vacuum system with an inert gas is essential to produce expanded aluminum materials. Additionally, a method of pressing sodium chloride into an aluminum alloy melt has been developed; the minimum pressure of 150 MPa was important for successful pressing process. Properties of produced materials (particularly relative density, porosity, Young’s modulus of elasticity, thermal conductivity) were studied on the obtained samples of porous aluminum materials.

Similar content being viewed by others

REFERENCES

S. F. Aida, M. N. Hijrah, A. H. Amirah, H. Zuhailawati, and A. S. Anasyida, “Effect of NaCl as a space holder in producing open cell A356 aluminum foam by gravity die casting process,” Procedia Chem. 19, 234 – 240 (2016).

Z. Hussain, and N. S. A. Suffin, “Microstructure and mechanical behaviour of aluminum foam produced by sintering dissolution process using NaCl space holder,” J. Eng. Sci. 7, 37–49 (2011).

S. Báez-Pimiento M. E. Hernández-Rojas, M. Palomar-Pardavé, “Processing and characte-rization of open–cell aluminum foams obtained through infiltration processes,” Procedia Mater. Sci., No. 9, 54–61 (2015).

H. Bafti and A. Habibolahzadeh, “Production of aluminum foam by spherical carbamide space holder technique-processing parameters,” Mat. Des. 31, 4122–4129 (2010).

J. Banhart and H. Eifert, Metal Foams (Verlag MIT Publishing, Bremen, 1997).

J. Banhart, “Manufacture, characterisation and application of cellular metals and metal foams,” Prog. Mater. Sci. 46, 559–635 (2001).

G. J. Davies and S. Zhen, “Metallic foams: “Their production, properties and applications,” J. Mater. Sci. 18, 1899–1911 (1983).

L. J. Gibson and M. F. Ashby, Cellular Solids: Structure and Properties, 2nd ed. (Cambridge University Press, 1999).

J. Jerz, “Foamed aluminum and aluminum alloys prepared by powder metallurgy,” Ph.D thesis (TU Vienna, 1995).

F. G. Moreno, “Commercial application of metal foams: Their properties and production,” Materials 9, 1–27 (2016).

E. M. Luna, F. Barari, R. Woolley, and R. Coddall, “Casting protocols for the production of open cell aluminum foams by the replication technique and the effect on porosity,” J. Visualized Exp. 94, 52268 (2014).

I. Sh. Trakhtenberg, A. A. Borisov, V. I. Novozhonov, A. P. Rubshtein, A. B. Vladimirov, A. V. Osipenko, V. A. Mukhachev and E. B. Makarova, “Mechanical properties and the structure of porous titanium obtained by sintering compacted titanium sponge,” Phys. Met. Metallogr. 105, No. 1, 92–97 (2008).

N. B. Pugacheva, N. S. Michurov, and T. M. Bykova, “Structure and properties of the Al/SiC composite material,” Phys. Met. Metallogr. 117, No. 6, 634–640 (2016).

A. V. Pozdniakov, A. Lotfy, A. Qadir, and V. S. Zdoto-revskiy, “Effect of the B4C content on the structure and thermal expansion coefficient of the Al–5% Cu alloy-based metal-matrix composite material,” Phys. Met. Metallogr. 117, No. 8, 783–788 (2016).

L. S. Vasil’ev and S. L. Lomaev, “Influence of pressure on of formation and evolution of the nanostructure in plastically deformed metals and alloys,” Phys. Met. Metallogr. 120, No 6, 600–606 (2019).

A. S. Tsapleva, I. M. Abdyukhanov, K. O. Bazaleeva, A. A. Aleksandrova, and M. V. Alekseev, “Texture of Nb filaments and Nb3Sn phase in technical superconductors fabricated by bronze and internal-tin-source techniques,” Phys. Met. Metallogr. 121, No. 5, 471–475 (2020).

F. Bainbridge and J. A. Taylor, “The surface tension of pure aluminum and aluminum alloys,” Metall. Mater. Trans. A 44, 3901–3909 (2013).

I. Egry, E. Ricci, R. Novakovic, and S. Ozawa, “Surface tension of liquid matals and alloys—Recent development,” Adv. Colloid Interf. Sci. 159, 198–212 (2010).

H. Darcy, “Les fontaines publiques de la ville de dijon”. Exposition et application des principles á suivre et des formulaes á employer dans les questions de distribution d’ean. (Victor Dalmont, Paris, 1856).

J. Vohlídal, K. Štulík, and A. Julák, Chemical and Analytical Tables Grada Publishing, Prague, 1999) (in Czech).

J. Novák, et al., Physical Chemistry for Bachelor and Master Courses (VŠCHT, Praha, 2016) (in Czech).

E. L. Furman, A. B. Finkestein, and M. L. Cherny, “Permeability of aluminum foams produced by replication casting”. Metals 3, No. 1, 49–57 (2013).

E. L. Furman, A. B. Finkelstein, and M. L. Cherny, “The anisotropy of replicated aluminum foams,” Adv. Mater. Sci. Eng., Article ID 230767, 1–6 (2014

E. L. Furman, A. B. Finkelstein, and Y. Yun, “Tensile strength analysis of oxide film on the aluminum melt surface”, in Proceedings of the 11th Russian Conference on Structure and properties of metal and slag melts (South Urals State University, Ekaterinburg, 2004), Vol. 2, pp. 213–215.

J. F. Despois and A. Mortensen, “Permeability of open-pore microcellular materials,” Acta Mater. 53, No. 5, 1381–1388 (2005).

A. Jinnapat, and A. Kennedy, “The manufacture and characterisation of aluminum foams made by investment casting using dissolvable spherical sodium chloride bead preforms,” Metals 1, No. 1, 49–64 (2011).

J. S. Aronofsky and R. Jenkins, “Unsteady flow of gases through porous media,” in Proceedings of the 1st US National Congress of Applied Mechanics (Illinois Institute of Technology, Chicago, 1952), pp. 763–771.

J. Dinicolantonio, The Salt Fix: Why the Experts got All Wrong – and How Eating More Might Save Your Life, 1st ed (Brno, 2017).

I. Nová, K. Fraňa, J. Sobotka, P. Solfronk, D. Koreček, and I. Nováková, “Production of porous aluminum using sodium chloride,” Manuf. Technol. 19, No. 5, 817–822 (2019).

Technical Material EXXENTIS AG (www.exxentis.com).

Funding

The work has been financially supported by the project “Hybrid materials for hierarchical structures”, research goal: Composite materials and structures, research program: Materials and structures on the metal basis, reg. no. CZ.02.1.01/0.0/0.0/16_019/0000843 provided by the European Union and the Czech government.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nová, I., Fraňa, K. & Lipiňki, T. Monitoring of the Interaction of Aluminum Alloy and Sodium Chloride as the Basis for Ecological Production of Expanded Aluminum. Phys. Metals Metallogr. 122, 1288–1300 (2021). https://doi.org/10.1134/S0031918X20140124

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20140124