Abstract

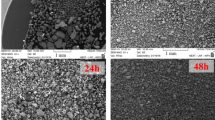

Ni3Si nanocrystalline powder was synthesized by mechanical alloying using a mixture of Ni and Si powders as raw materials. The structure and phase evolution, thermal stability and formation mechanism of Ni3Si powders during mechanical milling were investigated. The results showed that the intermediate phases Ni31Si12 and Ni74Si26 were formed firstly during high energy ball milling. After milling for 30 h, the Ni3Si nanocrystalline powder was finally attained by a series of reactions. Thermal analysis showed that the milled Ni3Si powder was stable during an annealing at 900°C for 2 h. Annealing of the milled powder leads to grain growth, decrease of microhardness, and transformation from disordered structure to ordered structure. Based on Miedema’s semi-empirical theory, the thermodynamic assessment calculation of Ni–Si powder mixtures during mechanical alloying was carried out. The thermodynamic calculation results are in accordance with the experiments.

Similar content being viewed by others

REFERENCES

M. Gogebakan, C. Kursun, K. O. Gunduz, M. Tarakci, and Y. Gencer, “Microstructural and mechanical properties of binary Ni–Si eutectic alloys,” J. Alloys Compd. 643, 219–225 (2015).

C. D. Xia, W. Zhang, Z. Y. Kang, Y. L. Jia, Y. F. Wu, R. Zhang, G. Y. Xu, and M. P. Wang, “High strength and high electrical conductivity Cu–Cr system alloys manufactured by hot rolling-quenching process and thermomechanical treatments,” Mater. Sci. Eng., A 538, 295–301 (2012).

M. Song, Y. Yang, M. Wang, W. J. Kuang, C. R. Lear, and G. S. Was, “Probing long-range ordering in nickel-base alloys with proton irradiation,” Acta Mater. 156, 446–462 (2018).

A. A. Al-Joubori, and C. Suryanarayana, “Synthesis of stable and metastable phases in the NiSi system by mechanical alloying,” Powder Technol. 302, 8–14 (2016).

A. T. Dutra, P. L. Ferrandini, and R. Caram, “Microstructure and mechanical behavior of in situ Ni–Ni3Si composite,” J. Alloys Compd. 432, 167–171 (2007).

B. G. Zhang, X. P. Li, T. Wang, and Z. Liu, “Microstructures and mechanical properties of directionally solidified Ni–25% Si full lamellar in situ composites,” Mater. Sci. Eng., A 674, 242–249 (2016).

X. P. Li, B. G. Zhang, T. Wang, Z. Liu, and T. Yu, “The formation of full lamellar structures from Ni–25 at % Si melts,” J. Alloys Compd. 672, 578–581 (2016).

R. Ahmad, R. F. Cochrane, and A. M. Mullis, “The formation of regular αNi-γ(Ni31Si12) eutectic structures from undercooled Ni–25 at % Si melts,” Intermetallics 22, 55–61 (2012).

T. Takasugi, M. Nagashima, and O. Izumi, “Strengthening and ductilization of Ni3Si by the addition of Ti elements,” Acta Metall. Mater. 38, 747–755 (1990).

K. Ohira, Y. Kaneno, H. Tsuda, and T. Takasugi, “Further investigation on phase relation and microstructures in Ni3Si–Ni3Ti–Ni3Nb pseudo-ternary alloy system,” Intermetallics 14, 367–376 (2006).

Y. Wang, J. Yang, J. H. Huang, Z. Cheng, W. L. Wang, S. H. Chen, and Y. Zhao, “Hot isostatic diffusion bonding tungsten alloy and high-strength steel Part I: Design and preparation of Ni–Si–B interlayer by magnetron sputtering,” J. Manuf. Processes 35, 360–367 (2018).

J. Lapin, and K. Kamyshnykova, “Processing, microstructure and mechanical properties of in-situ Ti3Al + TiAl matrix composite reinforced with Ti2AlC particles prepared by centrifugal casting,” Intermetallics 98, 34–44 (2018).

L. F. Wei, Z. L. Zhao, J. J. Gao, K. Cui, J. Y. Guo, S. Chen, and L. Liu, “Morphological instability of lamellar structures in directionally solidified Ni–Ni3Si alloys,” J. Cryst. Growth 483, 275–280 (2018).

M. Y. Niu, Q. L. Bi, L. Q. Kong, J. Yang, and W. M. Liu, “A study of Ni3Si-based composite coating fabricated by self-propagating high temperature synthesis casting route,” Surf. Coat. Technol. 205, 4249–4253 (2011).

Z. Yazdani, F. Karimzadeh, and M. H. Abbasi, “Formation mechanism of NbSi2–Al2O3 nanocomposite subject to mechanical alloying,” Adv. Powder Technol. 25, 1357–1361 (2014).

M. Rafiei, M. H. Enayati, and F. Karimzadeh, “Characterization and formation mechanism of nanocrystalline (Fe,Ti)3Al intermetallic compound prepared by mechanical alloying,” J. Alloys Compd. 480, 392–396 (2009).

G. K. Williamson, and W. H. Hall, “X-ray line broadening from filed aluminum and wolfram,” Acta Metall. 1, 22–31 (1953).

A. R. Miedema, P. F. de Châtel, and F. R. deBoer, “Cohesion in alloys—fundamentals of a semi-empirical model,” Phys. B 100, 1–28 (1980).

Y. Y. Fu, G. X. Hu, W. Y. Yang, and Z. Q. Sun, “Thermodynamical analysis on the metastable transitions of a multi-phase Al3Ti-based intermetallic compound during high-energy ball-milling,” Acta Metall. Sin. (Engl. Lett.) 36, 455–458 (2000).

C. J. Cui, J. Zhang, K. Wu, D. N. Zou, Y. P. Ma, L. Liu, and H. Z. Fu, “Directional growth charater of the Ni–11.5 wt % Si eutectic alloy,” Rare Met. Mater. Eng. 41, 650–653 (2012).

S. Z. Anvari, F. Karimzadeh, and M. H. Enayati, “Synthesis and characterization of NiAl–Al2O3 nanocomposite powder by mechanical alloying,” J. Alloys Compd. 477, 178–181 (2009).

C. Suryanarayana, “Mechanical alloying and milling,” Progr. Mater. Sci. 46, 1–184 (2001).

M. Z. Mehrizi, and R. Beygi, “Direct synthesis of Ti3AlC2–Al2O3 nanocomposite by mechanical alloying,” J. Alloys Compd. 740, 118–123 (2018).

C. Suryanarayana, and A. A. Al-Joubori, “Effect of initial composition on phase selection in Ni-Si powder blends processed by mechanical alloying,” Mater. Manuf. Processes 33, 1–9 (2017).

H. Bakker, G. G. Zhou, and H. Yang, “Mechanical driven disorder and phase transformations in alloys,” Prog. Mater Sci. 39, 159–241 (1995).

ACKNOWLEDGMENTS

The authors are grateful to Mr. Deshun Liu for his assistance in the experiments of annealing.

Funding

This research was supported by the Natural Science Foundation of Shandong Province of China (grant no. ZR2018MEM005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, H., Liu, Y.T., Zhao, Y. et al. Characterization, Formation Mechanism, and Thermodynamics of Nanocrystalline Ni3Si Powder Prepared by Mechanical Alloying. Phys. Metals Metallogr. 121, 1266–1272 (2020). https://doi.org/10.1134/S0031918X20130037

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20130037