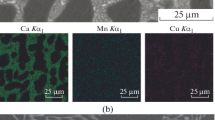

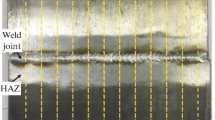

Abstract—This paper examines manufacturability problems of a new Al–Ca–La–Mn alloy in the process of pressure treatment. Electron microscopy and X-ray diffraction analysis were used to perform a detailed study of the structure of the alloy in the cast state and after thermomechanical treatment under different conditions. The cast structure of the alloy is shown to consist of the Al-based solid solution (Al) and Al4(Ca,La) eutectic phase, whose volume fraction is ~15%. The metallographic analysis of the alloys subjected to hot and cold rolling, as well as cold drawing, was performed; a substantial refining of eutectic intermetallics compared to that in the cast state was found. In particular, the homogeneous distribution of submicron spherical particles (300–500 nm in size) in the volume of composite material is observed, which are efficient stabilizers of the structure upon recrystallization. The obtained samples of rolled sheets demonstrate the high thermal stability of the structure and properties during long-term isothermal holding at 250 and 350°С. In particular, it has been shown that the 10-h annealing of cold-rolled sheet 1 mm thick at 250°С leads to a decrease in the hardness only by ~15%. The most favorable conditions for manufacturing the rolled sheets allow us to reach high mechanical properties (an ultimate strength of 240–290 MPa, a yield strength of 200–250 MPa, and a relative elongation of 5.5–15.5%).

Similar content being viewed by others

REFERENCES

A. V. Pozdnyakov, R. Yu. Barkov, Zh. Sarsenbaev, E. Kkhamees, and A. S. Prosviryakov, “Evolution of microstructure and mechanical properties of a new Al–Cu–Er wrought alloy,” Phys. Met. Metallogr. 120, 614–619 (2019).

A. V. Pozdniakov and R. Y. Barkov, “Microstructure and materials characterisation of the novel Al–Cu–Y alloy,” Mater. Sci. Technol. 34, 1489–1496 (2018).

L. Zhang, P. J. Masset, F. Cao, F. Meng, L. Liu, and Z. Jin, “Phase relationships in the Al-rich region of the Al–Cu–Er system,” J. Alloys Compd. 509, 3822–3831 (2011).

L. G. Zhang, L. B. Liu, G. X. Huang, H. Y. Qi, B. R. Jia, and Z. P. Jin, “Thermodynamic assessment of the Al–Cu–Er system,” CALPHAD: Comput. Coupling Phase Diagrams Thermochem. 32, 527–534 (2008).

N. A. Belov, A. V. Khvan, and A. N. Alabin, “Microstructure and phase composition of Al–Ce–Cu alloys in the Al-rich corner,” Mater. Sci. Forum, 395–400 (2006).

N. A. Belov and A. V. Khvan, “The ternary Al–Ce–Cu phase diagram in the aluminum-rich corner,” Acta Mater. 55, 5473–5482 (2007).

L. F. Mondolfo, Aluminum Alloys: Structure and Properties (Butterworths, London, 1976).

N. Belov, E. Naumova, T. Akopyan, and V. Doroshenko, “Phase diagram of Al–Ca–Mg–Si system and its application for the design of aluminum alloys with high magnesium content,” Metals 7, 429–445 (2017).

J. Yurong, S. Xi, B. Xiaoheng, H. Ye, H. Shuaixiong, W. Di, B. Weimin, L. Libin, and Z. Ligang, “Experimental investigation and thermodynamic assessment of Al–Ca–Ni ternary system,” J. Mater. Sci. 52, 12 409–12 426 (2017).

T. K. Akopyan, N. V. Letyagin, and V. V. Doroshenko, “Aluminum matrix composites based on Al–Ca–Ni–Ce system, strengthened with nanoparticles of L12 phase without use of quenching,” Tsvetn. Met., No. 12, 56–61 (2018).

E. A. Naumova, T. K. Akopyan, N. V. Letyagin, and M. A. Vasina, “Investigation of the structure and properties of eutectic alloys of the Al–Ca–Ni system containing REM,” Non-ferrous Met., No. 2, 25–30 (2018).

N. A. Belov, E. A. Naumova, A. N. Alabin, and I. A. Matveeva, “Effect of scandium on structure and hardening of Al–Ca eutectic alloys,” J. Alloys Compd. 646, 741–747 (2015).

N. A. Belov, T. K. Akopyan, S. S. Mishurov, and N. O. Korotkova, “Effect of Fe and Si on the microstructure and phase composition of the aluminum-calcium eutectic alloys,” Non-Ferrous Met., No. 2, 37–42 (2017).

N. A. Belov, E. A. Naumova, T. K. Akopyan, et al., “Phase diagram of the Al–Ca–Fe–Si system and its application for the design of aluminum matrix composites,” JOM 70, 2710–2715 (2018).

P. K. Shurkin, A. P. Dolbachev, E. A. Naumova, and V. V. Doroshenko, “Effect of iron on the structure, strengthening, and physical properties of Al–Zn–Mg–Ca alloys,” Tsvetn. Met., No. 5, 69–77 (2018).

T. K. Akopyan, N. V. Letyagin, N. A. Belov, and P. K. Shurkin, “New eutectic type Al alloys based on the Al–Ca–La (Zr, Sc) system,” Mater. Today: Proc. 19, 2009–2012 (2019).

H. Yang, L. Jianhua, Q. Shengtao, D. Zhenqiang, Z. Jie, and S. Yaozu, “Microstructure evolution and mechanical properties of Al–La alloys with varying La contents,” Mater. Sci. Eng., A 701, 134–142 (2017).

Z. Cao, G. Kong, C. Che, Y. Wang, and H. Peng, “Experimental investigation of eutectic point in Al-rich Al–La, Al–Ce, Al–Pr and Al–Nd systems,” J. Rare Earths 35, 1022–1028 (2017).

T. K. Akopyan, N. A. Belov, E. A. Naumova, and N. V. Letyagin, “New in-situ Al matrix composites based on Al–Ni–La eutectic,” Mater. Lett. 245, 110–113 (2019).

T. K. Akopyan, N. V. Letyagin, and M. E. Samoshina, “Al–Ca–Ni–La–Fe in-situ aluminum-matrix eutectic composites,” Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., No. 4, 57–69 (2019).

A. E. Medvedev, M. Y. Murashkin, N. A. Enikeev, I. Bikmukhametov, R. Z. Valiev, P. D. Hodgson, and R. Lapovok, “Effect of the eutectic Al–(Ce, La) phase morphology on, mechanical properties, electrical conductivity and heat resistance of Al–4.5(Ce, La) alloy after SPD and subsequent annealing,” J. Alloys Compd. 796, 321–330 (2019).

Y. Liu, Z. Bian, Z. Chen, M. Wang, D. Chen, and H. Wang, “Effect of Mn on the elevated temperature mechanical properties of Al–La alloys,” Mater. Charact. 155, 109 821 (2019).

I. J. Polmear, Light Metals: From Traditional Alloys to Nanocrystals, 4th ed. (Elsevier, Oxford, 2006).

N. O. Korotkova, N. A. Belov, V. N. Timofeev, M. M. Motkov, and S. O. Cherkasov, “Influence of Heat Treatment on the Structure and Properties of an Al–7% REM Conductive Aluminum Alloy Casted in an Electromagnetic Crystallize,” Phys. Met. Metallogr. 121, 173–179 (2020).

Funding

The study was supported by the Russian Science Foundation, project no. 18-79-00345.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akopyan, T.K., Letyagin, N.V., Belov, N.A. et al. Analysis of the Microstructure and Mechanical Properties of a New Wrought Alloy Based on the ((Al) + Al4(Ca,La)) Eutectic. Phys. Metals Metallogr. 121, 914–919 (2020). https://doi.org/10.1134/S0031918X20080025

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20080025