Abstract

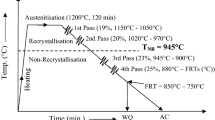

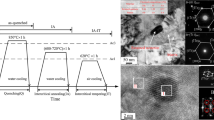

Ultrahigh level of strength, toughness, good weldability, and also weight reduction are the key issues in the automotive and structural industries for improving fuel efficiency and the economy of structure fabrication. The present investigation has produced an ultrahigh strength low carbon Cu bearing steel through the thermo-mechanically controlled processing (TMCP). Here Cu not only acts as a precipitation former but also delays the recrystallisation through a solute drag effect. The steel shows Cu-rich precipitates within the bainite-martensite microstructure. Cu-rich particles within the lower bainite, precipitation strengthening, solid solution strengthening, and delayed recrystallisation significantly improve the yield strength (≈1.25 GPa) and the strain hardening ability. The present steel has shown an excellent combination of mechanical properties comprising of ultra-high ultimate tensile strength >1550 MPa with ductility >12% and satisfactory low-temperature toughness (28 J/cm2). The investigated steel with low carbon content is expected to have good weldability.

Similar content being viewed by others

REFERENCES

V. A. Kozvonin, A. A. Shatsov, I. V. Ryaposov, M. G. Zakirova, and K. N. Generalova, “Structure, phase transformations, mechanical characteristics, and cold resistance of low-carbon martensitic steels”, Phys. Met. Metallogr. 117, 834–842 (2016).

S. K. Ghosh, P. S. Bandyopadhyay, S. Kundu, and S. Chatterjee, “Copper bearing microalloyed ultrahigh strength steel on a pilot scale: Microstructure and properties”, Mater. Sci. Eng., A 528, 7887–7894 (2011).

M. Zhao, K. Yang, and Y. Shan, “The effects of thermo-mechanical control process on microstructures and mechanical properties of a commercial pipeline steel”, Mater. Sci. Eng., A 335, 14–20 (2002).

B. E. Keehan, L. Karlsson, H. O. Andren, and H. K. D. H. Bhadeshia, “New developments with C–Mn–Ni high strength steel weld metals. Part A. microstructure”, Weld. J. 85, 200–210 (2006).

Z. B. Jiao, J. H. Luan, M. K. Miller, and C. T. Liu, “Precipitation mechanism and mechanical properties of an ultra-high strength steel hardened by nanoscale NiAl and Cu particles”, Acta Mater. 97, 58–67 (2015).

S. Chatterjee and S. K. Ghosh, “Evolution of microstructures and mechanical properties of thermomechanically processed ultrahigh strength”, Int. J. Metall. Eng. 2, 92–99 (2013).

X. M. Wang and X. L. He, “Effect of boron addition on structure and properties of low carbon bainitic steels”, ISIJ Int. 42, 38–46 (2002).

H. Song, J. Yoo, S-H. Kim, S. S. Sohn, M. Koo, N. J. Kim, and S. Lee, “Novel ultra-high-strength Cu-containing medium-Mn duplex lightweight steels”, Acta Mater. 135, 215–225 (2017).

A. Karmakar, S. Biswas, S. Mukherjee, D. Chakrabarti, and V. Kumar, “Effect of composition and thermo-mechanical processing schedule on the microstructure, precipitation and strengthening of Nb-microalloyed steel”, Mater. Sci. Eng., A 690, 158–169 (2017).

G. Mandal, S. K. Ghosh, D. Chakrabarti, and S. Chatterjee, “Effects of thermo-mechanical process parameters on microstructure and crystallographic texture of high Ni–Mo ultrahigh strength steel”, Metallogr., Microstruct., Anal. 7, 222–238 (2018).

C. Jun, T. Shuai, L. Zhen-Yu, and W. Guo-Dong, “Microstructural characteristics with various cooling paths and the mechanism of embrittlement and toughening in low-carbon high performance bridge steel”, Mater. Sci. Eng., A 559, 241–249 (2013).

N. Tsuji, R. Ueji, Y. Minamino, and Y. Saito, “A new and simple process to obtain nano-structured bulk low-carbon steel with superior mechanical property”, Scr. Mater. 46, 305–310 (2002).

Y. H. Zhao, X. Z. Liao, Z. Jin, R. Z. Valiev, and Y. T. Zhu, “Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing”, Acta Mater. 52, 4589–4599 (2004).

A. Yu. Kaletin and Yu. V. Kaletina, “The role of retained austenite in the structure of carbide-free bainite of construction steels”, Phys. Met. Metallogr. 119, 893–898 (2018).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mandal, G., Ghosh, S.K., Chakrabarti, D. et al. Influence of TMCP Parameters on Structure and Properties of Low Carbon Cu Bearing Ultra-High Strength Steel. Phys. Metals Metallogr. 121, 269–275 (2020). https://doi.org/10.1134/S0031918X2002012X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X2002012X