Abstract

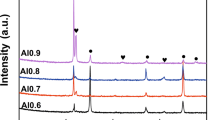

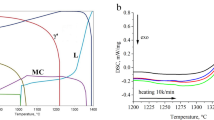

In the present work, a study was carried out for various possible Mg concentrations in order to optimize Mg amount in Al–Mg system as far as metallurgical and mechanical properties are concerned. In molten Al, variations of amount of Mg were made from 0.05–7 wt % Mg using a resistance heating furnace. Intermetallics like Al–Mg, Mg–Si, Al–Si, etc.,—were formed at processing temperature. During solidification, these intermetallics were pushed towards the grain boundaries and formed clusters, which was studied using SEM–EDS analysis. Heavier phases revealed as dark regions whereas lighter phases as less dark or bright regions. Due to such pushing effects of intermetallics during solidifications of bath in metallic die, development of grain boundaries started in the form of remarkable thickening of it into the Al matrix. This phenomenon was found to be more pronounced, as the Mg concentration was increased. Hence, in case of 7 wt % Mg, it was found that maximum amount of intermetallics gathered at grain boundaries. Segregation tendencies of various intermetallics and excess free Mg were found non uniform for a higher range of Mg. Ultimate tensile strength, specific strength, and hardness properties were studied and they were found to be highest in Al–3 wt % Mg system along with low density and ductility values. Therefore, in the present study, 3 wt % Mg is considered to be an optimum level of Mg concentration based on its micro-mechanical behaviour.

Similar content being viewed by others

REFERENCES

S. Das, D. P. Mondal, S. Sawla, N. Ramakrishnan, “Synergic effect of reinforcement and heat treatment on the two body abrasive wear of an Al–Si alloy under varying loads and abrasive sizes,” Wear 264, 47–59 (2008).

R. S. Rana and Rajesh Purohit, “Effect of magnesium enhancement on mechanical property and wear behavior of LM aluminum alloy,” Int. J. Sci. Eng. Res. 3 (7), (2012).

Feng Yan, Shou Xun Ji, and Zhong Yun Fan, “Effect of excess Mg on the microstructure and mechanical properties of Al–Mg2Si high pressure die casting alloys,” Mater. Sci. Forum 765, 64–68 (2013).

Joseph R. Davis, Corrosion of Aluminum and Aluminum Alloys ASM International (1999).

Lucio F. Mondolfo, Aluminum Alloys: Structure and Properties (Elsevier, 2013).

S. G. Alieva, M. B. Altman, S. M. Ambartsumyan, F. I. Kvasov, I. N. Fridlyander, and A. F. Belov, Industrial Aluminum Alloys (Metallurgiya, Moscow, 1984) [in Russian].

K. V. Sharma and H. N. Girisha, “Effect of Mg and unidirectional solidification on strength and microstructure of Al–Cu–Mg alloy,” Int. J. Sci. Eng. Research 3, 171–174 (2013).

A. Abdulhaqq, JainS. C. Hamid, P. K. Ghosh, and Ray. Subrata, “Processing, Microstructure, and Mechanical Properties of Cast In-Situ Al(Mg, Mn)–Al2O3(MnO2) Composite,” Metal. Mater. Trans. A 36 (8), 2211–2223 (2005).

R. S. Rana, Rajesh Purohit, and S. Das, Reviews on the influences of alloying elements on the microstructure and mechanical properties of aluminum alloys and aluminum alloy composites, Int. J. Sci. Res. Publications, Volume 2, Issue 6, June 2012.

Lucky Agrawal, Rakesh Yadav, and Abhished Sexena, “Effect of magnesium content on the mechanical properties of Al–Zn–Mg alloys,” Int. J. Emerging Technologies 3 (1), 137–140 (2012).

Md Habibur Rahman and H. M. M. A. Rashed, “Effect of magnesium on wear characteristics of silicon carbide and alumina reinforced aluminum-metal matrix composites,” Int. J. Sci. Eng. Res. 5, 1210–1213 (2014).

Luo Zhiping and Zhang Shaoqing, “Comment on the so-called Z-phase in magnesium alloys containing zinc and rare-earth elements,” J. Mater. Sci. Lett. 12, 1490–1492 (1993).

J. Zhang, Z. Fan, Y. Q. Wang, and B. L. Zhou, “Microstructure and mechanical properties of in situ Al–Mg2Si composites,” Mater. Sci. Techn. 16, 913–918 (2000).

M. Arun, N. Salim, and A. Kumar, “Effect of Mg enhancement in the microstructure and mechanical properties of AC2A Al alloy,” Int. J. Res. Eng. Techn. 2, 139–148 (2014).

K. U. Kainer, “Aluminum and magnesium based metal matrix composites,” Kovine, zlitine, technologije 30, 509–516 (1996).

J. Zhang, Z. Fan, Y. Q. Wang, and B. L. Zhou, “Equilibrium pseudobinary Al–Mg2Si Phase diagram,” Mater. Sci. Techn. 17, 494–496 (2001).

J. Zhang, Z. Fan, Y. Q. Wang, and B. L. Zhou, “Microstructural evolution of the in situ Al–15 wt % Mg2Si composite with extra Si contents,” Scr. Mater. 42, 1101–1106 (2000).

Y. Z. Lü, Q. D. Wang, X. Q. Zeng, Y. P. Zhu, and W. J. Ding, “Behavior of Mg–6Al–xSi alloys during solution heat treatment at 420°C,” Mater. Sci. Eng., A 301, 255–258 (2001).

Xiaoping Niu and Li Lu, “Formation of magnesium silicide by mechanical alloying,” Adv. Perf. Mater. 4, 275–283 (1997).

Vandana J. Rao, “Optimization of magnesium metal into commercially pure aluminum,” Int. J. Eng. Res. Appl. 4, 413–415 (2014).

J. Gubicza, N. Q. Chinh, Z. Horita, and T. G. Langdon, “Effect of Mg addition on microstructure and mechanical properties of aluminum,” Mater. Sci. Eng., A 387, 55–59 (2004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Panchal, H.N., Rao, V.J. Influence of Mg on Micro-Mechanical Behaviour of as Cast Al–Mg System. Phys. Metals Metallogr. 120, 881–887 (2019). https://doi.org/10.1134/S0031918X19090126

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X19090126