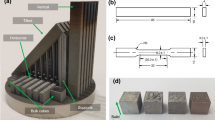

Abstract—Cryogenic treatments including shallow and deep cryogenic treatment are supplemental operations designed to improve wear resistance and increase the hardness of a variety of tool and hardening steels. In this research, the effect of cryogenic treatment was investigated on the microstructure and wear behavior (wear behavior in environment temperature and at 550°C) in H11 hot work tool steel. To do so, the samples were austenitized in 1050°C for 60 min and were quenched in oil. Then, the samples were put into dry ice (‒80°C) and liquid nitrogen (–196°C) under shallow and deep cryogenic treatments. Later, the samples were tempered at 550°C for 60 min. Scanning electron microscopy (SEM), optical microscopy (OM), and X-ray diffraction (XRD) analysis were used to analyze the microstructure and the pin on disk method was used to analyze the wear behavior. The results showed that the percentage of retained austenite reaches from 6.5% in quench–temper treatment (QT) to 3% in shallow and to less than 1% in deep cryogenic treatments. Moreover, the tiny carbides are generated (after tempering at 550°C) as a result of deep cryogenic treatment (DCT) and the amount of carbides reaches from 5.5% in QT treatment to 8.2% in DCT treatment. Moreover, in both deep and shallow cryogenic treatments compared to a quench-temper one with the hardness of 4 and 9%, wear resistance at ambient temperature reached 31 and 36% and the wear resistance at high temperature reached 30 and 40%. Additionally, the wear mechanism becomes an adhesive and tribochemical wear in the environment temperature and becomes an abrasive and tribochemical wear in the high temperatures. Conducting cryogenic treatment reduces the amount of adhesive and abrasive wear at the environment and high temperatures.

Similar content being viewed by others

REFERENCES

K. Amini, S. Nategh, A. Shafyei, and A. Rezaeian, “Effect of deep cryogenic treatment on the properties of 80CrMo12.5 tool steel,” Inter. J. Miner., Metall. Mater. 19, 30–37 (2012).

K. Amini, S. Nategh, A. Shafiey, and M. A. Soltany, “To study the effect of cryogenic heat treatment on the hardness and the amount of residual austenite in 1/2304 steel,” Metal. 13, 1–7 (2008).

F. Cajner, V. Leskovšek, D. Landek, and H. Cajner, “Effect of deep-cryogenic treatment on high speed steel properties,” Mater. Manufact. Processes 24, 743–746 (2009).

D. Das, A. Dutta, and K. Ray, “Influence of varied cryotreatment on the wear behavior of AISI D2 steel,” Wear 266, 297–309 (2009).

D. Das, A. K. Dutta, and K. K. Ray, “Sub-zero treatments of AISI D2 steel: Part I. Microstructure and hardness,” Mater. Sci. Eng., A 527, 2182–2193 (2010).

D. Das, K. Ray, and A. Dutta, “Influence of temperature of sub-zero treatments on the wear behaviour of die steel,” Wear 267, 1361–1370 (2009).

A. Bensely, A. Prabhakaran, D. M. Lal, and G. Nagarajan, “Enhancing the wear resistance of case carburized steel (En 353) by cryogenic treatment,” Cryogenics 45, 747–754 (2005).

F. Meng, K. Tagashira, and H. Sohma, “Wear resistance and microstructure of cryogenic treated Fe–1.4 Cr–1C bearing steel,” Scr. Metall. Mater. 31, 865–868 (1994).

M. Koneshlou, K. M. Asl, and F. Khomamizadeh, “Effect of cryogenic treatment on microstructure, mechanical and wear behaviors of AISI H13 hot work tool steel,” Cryogenics 51, 55–61 (2011).

F. Meng, K. Tagashira, R. Azuma, and H. Sohma, “Role of eta-carbide precipitations in the wear resistance improvements of Fe–12Cr–Mo–V–1.4 C tool steel by cryogenic treatment,” ISIJ Int. 34, 205–210 (1994).

K. Amini, A. Akhbarizadeh, and S. Javadpour, “Effect of deep cryogenic treatment on the formation of nano-sized carbides and the wear behavior of D2 tool steel,” Intern. J. Miner., Metall. Mater. 19, 795–799 (2012).

J. Huang, Y. Zhu, X. Liao, I. Beyerlein, M. Bourke, T. Mitchell, “Microstructure of cryogenic treated M2 tool steel,” Mater. Sci. Eng., A 339, 241–244 (2003).

A. Standard, “E975-03: Standard practice for X-ray determination of retained austenite in steel with near random crystallographic orientation,” ASTM, West Conshohocken, PA (2008).

A. Akhbarizadeh, A. Shafyei, and M. Golozar, “Effects of cryogenic treatment on wear behavior of D6 tool steel,” Mater. Design 30, 3259–3264 (2009).

D. Senthilkumar, I. Rajendran, M. Pellizzari, and J. Siiriainen, “Influence of shallow and deep cryogenic treatment on the residual state of stress of 4140 Steel,” J. Mater. Proces. Techn. 211, 396–401 (2011).

A. Akhbarizadeh, S. Javadpour, K. Amini, and A. H. Yaghtin, “Investigating the effect of ball milling during the deep cryogenic heat treatment of the 1.2080 tool steel,” Vacuum 90, 70–74 (2013).

K. Amini, A. Akhbarizadeh, and S. Javadpour, “Cryogenic heat treatment of the ferrous materials—A review of the current state,” Metal. Res. Techn. 113, 611 (2016).

A. Idayan, A. Gnanavelbabu, and K. Rajkumar, “Influence of deep cryogenic treatment on the mechanical properties of AISI 440C bearing steel,” Procedia Eng. 97, 1683–1691 (2014).

G. Fontalvo, R. Humer, C. Mitterer, K. Sammt, I. Schemmel, “Microstructural aspects determining the adhesive wear of tool steels,” Wear 260, 1028–1034 (2006).

H. Paydar, K. Amini, and A. Akhbarizadeh, “Investigating the effect of deep cryogenic heat treatment on the wear behavior of 100Cr6 alloy steel,” Kovove Mater.-Met. Mater. 52, 163–169 (2014).

K. Amini, A. Araghi, and A. Akhbarizadeh, “Effect of deep cryogenic heat treatment on the wear behavior of carburized DIN 1.7131 grade steel,” Acta Metal. Sinica (English Letters) 28, 348–353 (2015).

B. Bhushan, Introduction to Tribology (Wiley, New York, 2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jalil Soleimany, Ghayour, H., Amini, K. et al. The Effect of Deep Cryogenic Treatment on Microstructure and Wear Behavior of H11 Tool Steel. Phys. Metals Metallogr. 120, 888–897 (2019). https://doi.org/10.1134/S0031918X19090035

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X19090035