Abstract

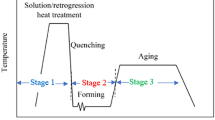

This paper presents the results of a study of structural transformations and the main tribological properties (coefficient of friction and wear rate) of Al–2.2 Li and Аl–3.1 Сu–2.0 Li–0.1 Zr (wt %) alloys. Optical metallography and transmission electron microscopy have been used to examine the alloy structure after heating and friction. Tribological tests of the alloys in pair with steel are carried out by sliding friction using a pin-on-plate scheme during reciprocating motion of a sample. The sliding velocity is 0.07 m/s and the load is 294 N. Friction is carried out in air and in a nitrogen gas at room temperature. Alloying of the Al–Li alloy with copper (3.1 wt %) and zirconium (0.1 wt %) is shown to significantly increase the wear resistance, enhance the frictional hardening, and reduce the friction coefficient of the alloys. The positive effect of this alloying on the tribological properties of the Al–Li alloy is caused by friction-induced severe strain hardening. A high-strength nanocrystalline structure consisting of a mixture of matrix crystals and a metastable δ' (Al3Li) phase is formed in a surface layer to 10 μm thick. Planar dislocation slip is observed in both alloys. This sliding mechanism is assumed to be related to the low (f ~ 0.25) coefficient of friction of both alloys. Artificial aging carried out under different four regimes increases the hardness of alloys, but significantly reduces their resistance to wear. This paper offers an explanation for the effects obtained.

Similar content being viewed by others

REFERFNCES

E. I. Lavernia, T. S. Strivatsan, and F. A. Mohamed, “Review strength, deformation, fracture behavior and ductility of aluminum–lithium alloys,” J. Mater. Sci. 25, 1137–1158 (1990).

I. N. Fridlyander, K. V. Chuistov, A. L. Berezina, and N. I. Kolobnev, Aluminum–Lithium Alloys. Structure and Properties (Naukova Dumka, Kiev, 1992) [in Russian]

P. N. Eswara, G. A. Amol, and R. J. H. Wanhill, Aluminum Lithium Alloys. Processing, Properties, and Applications (Elsevier, 2014).

L. I. Kaigorodova, D. Yu. Rasposienko, V. G. Pushin, V. P. Pilyugin and S. V. Smirnov, “Influence of severe plastic deformation on the structure and properties of Al–Li–Cu–Mg–Zr–Sc–Zn,” Phys. Met. Metallogr. 119, 161–168 (2018).

L. I. Kaigorodova, D. Yu. Rasposienko, V. G. Pushin, V. P. Pilyugin, and S. V. Smirnov, “Structure and mechanical properties of aging Al–Li–Cu–Zr–Sc–Ag alloy after severe plastic deformation by high-pressure torsion,” Phys. Met. Metallogr. 116, 346–355 (2015).

L. I. Kaigorodova, E. I. Sel’nikhina, and A. M. Drits, “Effect of quenching conditions on the microstructure, mechanical properties and corrosion resistance under stress of the alloy Al–Li–Cu–Zr,” Fiz. Met. Metalloved. 84, 642–649 (1997).

E. A. Lukina, A. A. Alekseev, V. V. Antipov, L. B. Khokhlatova, and P. L. Zhuravlev, “Phase transformations in commercial alloys 1424, V-1469, and 1441 during long-term low-temperature exposures,” Phys. Met. Metallogr. 112, 237–244 (2011).

M. S. Oglodkov, L. B. Khokhlatova, N. I. Kolobnev, A. A. Alekseev, and E. A. Lukina, “Effect of the thermomechanical treatment on Al (Al–Cu–Mg–Li–Zn) alloy properties and structure,” Sb. Aviats. Mater. Tekhnol. No. 4, 7–11 (2010).

M. N. Tosten, A. K. Vasudevan, and P. R. Howele, “The ageing characteristics of an Al-2 pct Li-3 pct Cu0.12 pct Zr alloy at 190°C,” Metall. Trans. A 19, 51–66 (1988).

L. G. Korshunov, N. L. Chernenko, I. G. Brodova and I. G. Shirinkina, “Effect of friction-induced deformation and oxidation on the structure and microhardness of surface aluminum and silumin layers,” Phys. Met. Metallogr. 118, 1113–1119 (2017).

Buckley, D.H., Surface Effects in Adhesion, Friction, Wear and Lubrication (Elsevier, Amsterdam, 1981; Mashinostroenie, Moscow, 1986).

L. G. Korshunov, “Structural transformations during friction and wear resistance of austenitic steels,” Phys. Met. Metallogr. 74, 150–162 (1992).

L. G. Korshunov, A. V. Makarov, and N. L. Chernenko, “Nanocrystalline structures of friction in steels and alloys, their strength and tribological properties,” in Razvitie idei akademika V. D. Sadovskogo (Develipment of Ideas pf Academician V. D. Sadovskii. Sbornik trudov (Ekaterinburg, 2008), pp. 218–241 [in Russian].

V. Gerold and H. P. Karnthaler, “On the origin of planar slip in F.C.C., alloys,” Acta Metall. 37, 2177–2183 (1989).

L. G. Korshunov, V. A. Shabashov, N. L. Chernenko, and V. P. Pilyugin, “Influence of contact stresses on the phase composition, strength and tribological properties of nanocrystalline structures arising in steels and alloys in sliding friction,” Metalloved. Term. Obrab. Met., No. 12, 24–34 (2008).

L. G. Korshunov, Yu. N. Goikhenberg, and N. L. Chernenko, “Effect of silicon on the structure, tribological behavior, and mechanical properties of nitrogen-containing chromium–manganese austenitic steels,” Phys. Met. Metallogr. 96, 535–544 (2003).

ACKNOWLEDGMENTS

The electron microscopic studies were performed at the Center of the Collaborative Access “Test Center of Nanotechnologies and Advanced Materials,” Institute of Metal Physics, Ural Branch, Russian Academy of Sciences.

This work was performed within the state assignment of FASO of Russia (theme “Structure” No. АААА-А18-118020190116-6) and supported in part by the Presidium of the Ural Branch of the Russian Academy of Sciences (project no. 18-10-2-39).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Gapontseva

Rights and permissions

About this article

Cite this article

Korshunov, L.G., Kaigorodova, L.I., Chernenko, N.L. et al. Tribological Properties and Structure of Aluminum—Lithium Alloys. Phys. Metals Metallogr. 119, 1236–1242 (2018). https://doi.org/10.1134/S0031918X18120086

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X18120086