Abstract

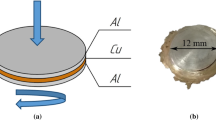

The structure and the mechanical and electrical properties of new ternary composites based on Al‒Mg deformable alloy obtained by fluid extrusion are studied. The evolution of structural and phase transformations in dissimilar fibers (Cu, Mg, and Al–Mg alloy) during thermomechanical treatment are studied using the methods of metallography, scanning electron microscopy, and hardness measurements. It is established that the strengthening of the ternary composite results from solid state reactions at the boundaries of the fiber, which lead to the formation of intermetallide phases (AlCu, Al2Cu, Mg2Cu, and MgCu2) and nonequilibrium supersaturated solid solutions of copper in aluminum and magnesium.

Similar content being viewed by others

REFERENCES

I. B. Peshkov, “The state and prospects of aluminum in the cable industry,” Kabeli i Provoda, No. 1, 7–9 (2009).

Overview of the Aluminum Rod Market (InfoMain. Dekabr’, Moscow, 2008) [in Russian].

N. A. Belov, A. N. Alabin, and A. Yu. Prokhorov, RF Patent No. 2010107317/02 (2010)

Yu. A. Gorbunov, “Role and prospects of rare-earth metals in the development of physico-mechanical characteristics and applications of deformable aluminum alloys,” Zh. Sibir. Federal. Univ. Ser. Engineer. Technol., 635–645 (2015).

D. I. Belyi, “Aluminum alloys for conductor cores of cable products,” Nauka Tekh. Kabeli Provoda, No. 1 (332), 8–15 (2012).

F. Wang, K. Wakoh, Y. Li, S. Ito, K. Yamanaka, Y. Koizumi, and A. Chiba, “Study of microstructure evolution and properties of Cu–Fe microcomposites produced by a pre-alloyed powder method,” Mater. Des. 126, 64–72 (2017).

S. Zhao, Z. Zheng, Z. Huang, S. Dong, P. Luo, Z. Zhang, and Y. Wang, “Cu matrix composites reinforced with aligned carbon nanotubes: Mechanical, electrical and thermal properties,” Mater. Sci. Eng., A 675, 82–91 (2016).

F. Bo, X. Yuncang, Y. Huihui, H. Rui, and L. Qing, “Mechanical behavior of a Mg/Al composite rod containing a soft Mg sleeve and an ultra hard Al core,” Mater. Sci. Eng., A 675, 204–211 (2016).

W. Yang, F. Bo, X. Yuncang, H. Rui, Y. Huihui, and L. Qing, “Microstructure mechanical behavior of a Mg AZ31/Al 7050 laminate composite fabricated by extrusion,” Mater. Sci. Eng., A 640, 454–459 (2015).

K. Maki, Y. Ito, H. Matsunaga, and H. Mori, “Solid solution copper alloys with high strength and high electrical conductivity,” Scr. Mater. 68, 777–780 (2013).

C. Zhu, A. Ma, J. Jiang, X. Li, D. Song, D. Yang, Y. Yuan, and J. Chen, “Effect of ECAP combined cold working on mechanical properties and electrical conductivity of Conform-produced Cu–Mg alloys,” J. Alloys Compd. 582, 135–140 (2014).

S. Gorsse, B. Ouvrard, M. Goune, and A. Poulon-Quintin, “Microstructural design of new high conductivity–high strength Cu-based alloy,” J. Alloys Compd. 633, 42–47 (2015).

A. Yu. Volkov, A. A. Kalonov, D. A. Komkova, and A. V. Glukhov, “Structure and properties of Cu/Mg-composites, obtained by hydroextrusion,” Phys. Met. Metallogr. 119 (10) (2018), (in press).

A. Yu. Volkov, O. S. Novikova, and B. D. Antonov, “The kinetics of ordering in an equiatomic CuPd alloy: A resistometric study,” J. Alloys Compd. 581, 625–631(2013).

T. P. Tolmachev, V. P. Pilyugin, A. I. Ancharov, E. G. Chernyshev, and A. M. Patselov, “The formation, structure, and properties of the Au–Co alloys produced by severe plastic deformation under pressure,” Phys. Met. Metallogr. 117, 135–142 (2016).

V. L. Gapontsev and V. V. Kondrat’ev, “Diffusion phase transformations in nanocrystalline alloys under severe plastic deformation,” Dokl. Phys. 385, 576–579 (2002).

V. M. Farber, “A contribution of diffusion processes into structure-formation upon the severe cold plastic deformation of metals,” Metalloved. Term. Obrab. Met., No. 8, 3–9 (2002).

M. Shtremel’, “The role of diffusion in the processes of mechanical alloying,” Metalloved. Term. Obrab. Met., No. 8, 10–12 (2002).

ACKNOWLEDGMENTS

This work was carried out within a state task from the Federal Agency of Scientific Organizations, subject “Structure”, project no. АААА-А18-118020190116-6.

The electron microscopy studies were performed in the Department of Electron Microscopy of the Institute of Metal Physics, Ural Branch, Russian Academy of Sciences, “Testing Center of Nanotechnologies and Unconventional Materials.”

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Chernokozhin

Rights and permissions

About this article

Cite this article

Brodova, I.G., Volkov, A.Y., Shirinkina, I.G. et al. Evolution of the Structure and Properties of Al/Cu/Mg Ternary Composites during Thermomechanical Treatment. Phys. Metals Metallogr. 119, 1210–1216 (2018). https://doi.org/10.1134/S0031918X18120050

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X18120050