Abstract

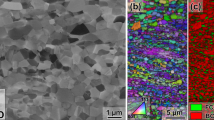

Because of the occurrence at a high temperature of the phase transformations, hot finishing rolling of the non-oriented electrical steel inevitably takes place in its multiphase condition. Because of the difference in lattice structure between ferrite and austenite, the constitutive model and softening mechanism should consider the phase differences. The combined effect of work hardening and dynamic softening is related not only to temperature, but also to the phase structure. In the present study, steady stress is determined to approximately represent the average deformation resistance referring to the characteristics of stress–strain curves and practice-connected rolling requirements. The constitutive models of the ferrite and austenite regions are established correspondingly by the Arrhenius equation. Metallographic observations revealed that the dominant softening mechanism in the austenite region is dynamic recrystallization and that in the ferrite region is dynamic recovery, which contributes to the elimination of some discrepancies over this issue. Furthermore, according to the relationship between steady stress and dislocation multiplication and annihilation from the dislocation model, an indicator called the hardening–softening ratio is proposed, which is proportional to the square of steady stress. It can be used to link up the macro steady stress and micro dislocation evolution and to quantify the combined effect of work hardening and dynamic softening in different phase regions.

Similar content being viewed by others

REFERENCES

A. R. He, J. Shao, W. Q. Sun, C. L. Guan, X. Y. Shen, and J. P. Zhang, “Transverse thickness deviation control of non-oriented silicon steel during cold rolling,” J. Mech. Eng. 47, 25–30 (2011).

J. X. Yan, W. Tang, L. Xiang, S. T. Qiu, and Y. H. Qi, “Phase transition point and high-temperature mechanical properties of non-oriented silicon steel,” Heat. Treat. Met. 40, 38–42 (2015).

J. G. Cao, H. Tang, G. H. Yang, D. Wen, Y. S. Zhou, and J. Q. Lai, “Finite element analysis of edge wave for non-oriented electrical strip with high temperature phase transition,” J. Mech. Eng. 48, 146–151 (2016).

J. G. Cao, T. C. Wang, H. B. Li, Y. Qiao, D. Wen, and Y. S. Zhou, “High-temperature constitutive relationship of non-oriented electrical steel based on modified Arrhenius model,” J. Mech. Eng. 52, 90–102 (2016).

J. F. Siciliano, K. Minami, T. M. Maccagno, and J. J. Jonas, “Mathematical modeling of the mean flow stress, fractional softening and grain size during the hot strip rolling of C-Mn steels,” ISIJ Int. 36, 1500–1506 (1996).

J. F. Siciliano, and J. J. Jonas, “Mathematical modeling of the hot strip rolling of microalloyed Nb, multiply-alloyed Cr-Mo, and plain C-Mn steels,” Metall. Mater. Trans. 31, 511–530 (2000).

Y. D. Xiao, M. Li, W. Wang, J. Zhou, G. L. Wu, and Y. M. Peng, “High temperature plastic deformation behavior of non-oriented electrical steel,” J. Cent. South Univ. Technol. 16, 25–31 (2009).

Y. Dong, Z. X. Gong, and G. H. Xiao, “Flow stress of plastic deformation for non-orientation electrical steel under high temperature,” J. Iron Steel Res. Int. 24, 53–58 (2012).

C. C. Chen, J. Shao, and A. R. He, “Research on online calculation methods of temperature field of hot strip,” J. Mech. Eng. 50, 135–142 (2014).

M. P. Phaniraj, B. B. Behara, and A. K. Lahiri, “Thermo-mechanical modeling of two phase rolling and microstructural evolution in the hot strip mill Part I. Prediction of rolling loads and finish rolling temperature,” J. Mater. Process. Technol. 170, 323–335 (2005).

M. P. Phaniraj, B. B. Behara, and A. K. Lahiri, “Thermo-mechanical modeling of two phase rolling and microstructural evolution in the hot strip mill Part-II. Microstructure evolution,” J. Mater. Process. Technol. 178, 388–394 (2006).

Y. B. Xu, Y. M. Yu, X. H. Liu, and G. D. Wang, “Prediction of rolling load, recrystallization kinetics, and microstructure during hot strip rolling,” J. Iron. Steel Res. Int. 14, 42–46 (2007).

P. Springer, and U. Prahl, “Characterisation of mechanical behavior of 18CrNiMo7-6 steel with and without Nb under warm forging conditions through processing maps analysis,” J. Mater. Process. Technol. 237, 216–234 (2016).

E. I. Poliak, and J. J. Jonas, “Initiation of dynamic recrystallization in constant strain rate hot deformation,” ISIJ Int. 43, 684–691 (2003).

J. J. Jonas, X. Quelennec, L. Jiang, and E. Martin, “The Avrami kinetics of dynamic recrystallization,” Acta Mater. 57, 2748–2756 (2009).

A. Yoshie, T. Fujita, M. Fujioka, K. Okamoto, and H. Morikawa, “Formulation of flow stress of Nb added steels by considering work-hardening and dynamic recovery,” ISIJ Int. 36, 467–473 (1996).

ACKNOWLEDGMENTS

The authors would like to thank the National Natural Science Foundation of China (grant nos. 51674028 and 51404021) for supporting this research.

Author information

Authors and Affiliations

Corresponding authors

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Liu, C., He, A.R., Qiang, Y. et al. Constitutive Model and Micro Hardening and Softening Mechanism for Nonoriented Electrical Steel. Phys. Metals Metallogr. 120, 69–77 (2019). https://doi.org/10.1134/S0031918X18080082

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X18080082