Abstract

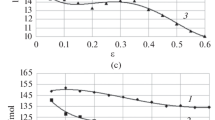

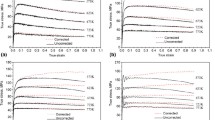

The deformation behavior of a 1981 aluminum alloy has been studied using a complex for simulating thermomechanical processes in the temperature range of 200–400°C at a deformation rate in the range of 0.001–10 s–1. The models of the relationships between the flow stress, temperature, and deformation rate have been constructed using a power-law dependence, exponential dependence, and hyperbolic-sine function on the Zener–Hollomon parameter (Z). In the calculations according to the power-law and exponential equations, discrepancies between the calculated and experimental values of the Zener–Hollomon parameter have been revealed at low and high values. These discrepancies are caused by the fact that the experimentally obtained dependences of the flow stress on the Z parameter over the entire range of its change with a single magnitude of the effective activation energy of the plastic deformation consist of two linear parts that correspond to the hot and warm deformation and have different magnitudes of the effective activation energy of plastic deformation with a lower value of the activation energy for hot deformation.

Similar content being viewed by others

References

Yu. _M. Vainblatt, “Formation of structure upon pressure treatment and subsequent heating,” in Structure and Properties of Semiproducts from Aluminum Alloys, (Metallurgiya, Moscow, 1984), Ch. 2, pp.15–29.

Yu. M. Vainblatt, “Diagrams of structural states and structure maps of aluminum alloy,” Izv. Akad. Nauk SSSR, Met., no. 2, 82–89 (1982).

L. B. Ber, “Mechanisms of structure development in wrought aluminum alloy semiproducts,” Tekhnol. Legk. Splavov, no. 1, 5–31 (2014).

Q. C. Fan, X. Q. Jiang, Z. H. Zhou, W. Ji, and H. Q. Cao, “Constitutive relationship and hot deformation behavior of Armco-type pure iron for a wide range,” Mater. Design 65, no. 2, 193–203 (2015).

B. Li, Q. Pan, Z. Zhang, and C. Li, “Characterization of flow behavior and microstructural evolution of Al–Zn–Mg–Sc–Zr alloy using processing maps,” Mater. Sci. Eng., A 556, 844–848 (2012).

S. Chen, K. Chen, G. Peng, X. Chen, and Q. Ceng, “Effect of heat treatment on hot deformation behavior and microstructure evolution of 7085 aluminum alloy,” J. Alloys Compd. 537, 338–345 (2012).

N. Jin, H. Zhang, Y. Han, W. Wu, and J. Chen, “Hot deformation behavior of 7150 aluminum alloy during compression at elevated temperature,” Mater. Character. 60, 530–536 (2009).

B. Wu, M. Q. Li, and D. W. Ma, “The flow behavior and constitutive equations in isothermal compression of 7050 aluminum alloy,” Mater. Sci. Eng., A 542, 79–87 (2012).

V. V. Teleshov, T. V. Bystryukova, V. V. Zakharov, E. Ya. Kaputkin, and G. M. Chugunkova, “Highstrength aluminum alloy of the Al–Zn–Mg–Cu system with a decreased density,” Tekhnol. Legk. Splavov, no. 4, 31–39 (2015).

V. V. Teleshov, V. V. Zakharov, T. V. Bystryukova, A. Yu. Churyumov, L. B. Ber, and G. M. Chugunkova, “Regularities of deformation and structure formation of high-strength 1981 alloy of the Al–Zn–Mg–Cu system with different scandium content,” Tekhnol. Legk. Splavov, no. 2, 25–36 (2016).

A. Yu. Churyumov, M. G. Khomutov, A. A. Tsar’kov, A. V. Pozdnyakov, A. N. Solonin, V. M. Efimov, and E. L. Mukhanov, “Study of the structure and mechanical properties of corrosion-resistant steel with a high concentration of boron at elevated temperatures,” Phys. Met. Metalogr. 115 (8), 809–813 (2014).

C. M. Sellars and W. J. McTegart, “On the mechanism of hot deformation,” Acta Metall. 14 (9), 1136–1138 (1966).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.Yu. Churyumov, V.V. Teleshov, 2017, published in Fizika Metallov i Metallovedenie, 2017, Vol. 118, No. 9, pp. 950–957.

Rights and permissions

About this article

Cite this article

Churyumov, A.Y., Teleshov, V.V. Quantitative description of the flow-stress dependence of aluminum alloys at the stage of steady flow upon hot deformation on the Zener–Hollomon parameter. Phys. Metals Metallogr. 118, 905–912 (2017). https://doi.org/10.1134/S0031918X17090046

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X17090046