Abstract

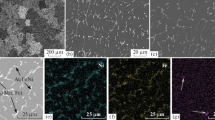

The results of studying the strength of a submicrocrystalline aluminum A5083 alloy (chemical composition was 4.4Mg–0.6Mn–0.11Si–0.23Fe–0.03Cr–0.02Cu–0.06Ti wt % and Al base) under shockwave compression are presented. The submicrocrystalline structure of the alloy was produced in the process of dynamic channel-angular pressing at a strain rate of 104 s–1. The average size of crystallites in the alloy was 180–460 nm. Hugoniot elastic limit σHEL, dynamic yield stress σy, and the spall strength σSP of the submicrocrystalline alloy were determined based on the free-surface velocity profiles of samples during shock compression. It has been established that upon shock compression, the σHEL and σy of the submicrocrystalline alloy are higher than those of the coarse-grained alloy and σsp does not depend on the grain size. The maximum value of σHEL reached for the submicrocrystalline alloy is 0.66 GPa, which is greater than that in the coarse-crystalline alloy by 78%. The dynamic yield stress is σy = 0.31 GPa, which is higher than that of the coarse-crystalline alloy by 63%. The spall strength is σsp = 1.49 GPa. The evolution of the submicrocrystalline structure of the alloy during shock compression was studied. It has been established that a mixed nonequilibrium grain-subgrain structure with a fragment size of about 400 nm is retained after shock compression, and the dislocation density and the hardness of the alloy are increased.

Similar content being viewed by others

References

G. V. Garkushin, G. E. Ivanchikhina, S. V. Razorenov, O. N. Ignatova, I. I. Kaganova, A.N. Malyshev, A.M. Podurets, V. A. Rayevskii, V. I. Skokov, and O. A. Tyupanova, “Mechanical properties of grade M1 copper before and after shock compression in a wide range of loading duration,” Phys. Met. Metallogr. 111, 197–206 (2011).

G. V. Garkushin, S. V. Razorenov, and G. I. Kanel, “Effect of structural factors on submicrosecond strength of D16T aluminum alloy,” Tech. Phys. 53, 1441–1446 (2008).

M. V. Aniskin, O. N. Ignatova, I. I. Kaganova, A. V. Kalmanov, E. V. Koshatova, A. I. Lebedev, V. V. Losev, A. M. Podurets, L. V. Polyakov, M. I. Tkachenko, A. N. Tsibikov, G. A. Salischev, G. V. Garkushin, S. V. Razorenov, and M. A. Zocher, “Mechanical properties of tantalum with different types of microstructure under high-rate deformation,” Phys. Mesomech. 14, 79–84 (2011).

S. V. Razorenov, G. V. Garkushin, G. I. Kanel’, and O. N. Ignatova, “Resistance to dynamic deformation and fracture of tantalum with different grain and defect structure,” Phys. Solid State 54, 790–797 (2012).

S. V. Razorenov, G. I. Kanel, and V. E. Fortov, “Submicrosecond strength of aluminum and an aluminum–magnesium alloy AMg6M at normal and enhanced temperatures,” Phys. Met. Metallogr. 95, 86–91 (2003).

G. I. Kanel, S. V. Razorenov, A. S. Savinykh, E. B. Zaretskii, and Yu. R. Kolobov, “Study of Structural Levels that Determine the Resistance to High-Strain-Rate Deformation and Fracture of Metals and Alloys,” Preprint OVT, Russian Academy of Sciences, No. 1-478, Moscow, 2004.

G. V. Garkushin, O. N. Ignatova, G. I. Kanel, L. W. Meyer, and S. V. Razorenov, “Submicrosecond strength of ultrafine-grained materials,” Mech.Solids 45, 624–632 (2010).

R. Z. Valiev, Y. Estrin, Z. Horita, T. G. Langdon, M. J. Zehetbauer, and Y. T. Zhu, “Fundamentals of superior properties in bulk nanoSPD materials,” Mater. Res. Lett. 4, 1–21 (2016).

I. G. Brodova, A. N. Petrova, I. G. Shirinkina, E. V. Shorokhov, I. V. Minaev, I. N. Zhgilev, and A. V. Abramov, “Fragmentation of the structure in Al-based alloys upon high speed effect,” Rev. Adv. Mater. Sci. 25, 128–135 (2010).

I. G. Brodova, A. N. Petrova, and I. G. Shirinkina, “Comparing specific features of the structural formation of aluminum alloys during severe and intense plastic deformation,” Tech. Phys. 76, 1233–1237 (2012).

I. G. Shirinkina, A. N. Petrova, I. G. Brodova, V. P. Pilyugin, and O. A. Antonova, “Phase and structural transformations in the aluminum AMTs alloy upon severe plastic deformation using various techniques,” Phys. Met. Metallogr. 113, 170–175 (2012).

I. G. Brodova, I. G. Shirinkina, A. N. Petrova, O. V. Antonova, and V. P. Pilyugin, “Evolution of the structure of V95 aluminum alloy upon high-pressure torsion,” Phys. Met. Metallogr. 111, 630–638 (2011).

I. G. Brodova, I. G. Shirinkina, A. N. Petrova, V. P. Pilyugin, and T. P. Tolmachev, “Structure of an AMTs aluminum alloy after high-pressure torsion in liquid nitrogen,” Phys. Met. Metallogr. 114, 667–671 (2013).

I. G. Brodova, A. N. Petrova, S. V. Razorenov, and E.V. Shorokhov, “Resistance of submicrocrystalline aluminum alloys to high-rate deformation and fracture after dynamic channel angular pressing,” Phys. Met. Metallogr. 116, 519–526 (2015).

Z. Zhao, L. Wang, D. Fan, B. X. Bie, X. M. Zhou, T. Sou, Y. L. Li, M. W. Chen, C. L. Liu, M. L. Qi, M. H. Zhu, and S. N. Luo, “Macrodeformation twins in singlecrystal aluminum,” Phys. Rev. Lett. 116, 075501 (2016).

E. V. Shorokhov, I. N. Zhgilev, and R. Z. Valiev, “Method of Material Dynamic Treatment,” RF Patent 2283717, Byull. Izobr., 2006, no.26.

A. N. Petrova, I. G. Brodova, and E. V. Shorokhov, “Structural refinement in Al–Mg–Mn alloy by the dynamic channel angular pressing method,” Perspekt. Mater. no. 12, 72–78 (2015).

I. G. Brodova, A. N. Petrova, S. V. Razorenov, O. P. Plekhov, and E. V. Shorokhov, “Deformation behavior of submicrocrystalline aluminum alloys during dynamic loading,” Russ. Metall. (Metally) 2016, 342–348 (2016).

T. Antoun, L. Seaman, D. R. Curran, G. I. Kanel, S.V. Razorenov, and A. V. Utkin, Spall Fracture (Springer, Berlin, 2000).

L. M. Barker and R. E. Hollenbach, “Laser interferometry for measuring high velocities of any reflecting surface,” J. Appl. Phys. 43, 4669–4675 (1972).

S. P. Marsh, LASL Shock Hugoniot Data (Univ. California Press, Berkeley, 1980).

G. I. Kanel’, S. V. Razorenov, A. V. Utkin, and V. E. Fortov, Shock-wave Effects in Condensed Media (Yanus-K, Moscow, 1996) [in Russian].

R. L. Whelchel, N. N. Thadhani, R. H. Sanders, L. J. Kecskes, and C. L. Williams, “Spall properties of Al5083 plate fabricated using equi-channel angular pressing (ECAP) and rolling,” J. Phys.: Conf. Ser. 500, 112006 (2014). doi 10.1088/1742-6596/500/11/112066

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Petrova, A.N., Brodova, I.G. & Razorenov, S.V. Strength properties and structure of a submicrocrystalline Al–Mg–Mn alloy under shock compression. Phys. Metals Metallogr. 118, 601–607 (2017). https://doi.org/10.1134/S0031918X17060072

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X17060072