Abstract

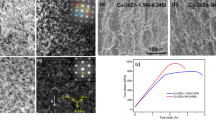

Tri-layered α-brass-clad Cu–Cr-alloy composite plates were prepared by hot roll-bonding. Neither intermetallic-compound layers nor interface defects were observed at the interfaces in the as-rolled and heat-treated α-brass-clad Cu–Cr composite plates. The hardness of the as-rolled α-brass layer was greater than that of the Cu–Cr substrate, since the α-brass was strengthened by strain hardening more efficiently upon rolling. The hardness of the α-brass decreased appreciably upon annealing because of the recovery processes, whereas that of the Cu–Cr layer slightly increased after heat treatment at 450°C due to the precipitation strengthening. After the post-roll-bonding heat treatment at 450°C, the strength of the α-brass-clad Cu–Cr-alloy composite decreased with a significant increase in ductility. The electrical conductivity of the asroll-bonded α-brass clad Cu–Cr alloy composite (47–52% IACS) increased significantly (to 72–74% IACS) after the 1-h heat treatment. The strength and conductivity of the clad composite are dependent on the precipitation strengthening of Cu–Cr and recovery softening of α-brass in the course of the post-roll-bonding heat treatment.

Similar content being viewed by others

References

I.-K Kim and S. I. Hong, “Effect of heat treatment on the bending behavior of tri-layered Cu/Al/Cu composite plates,” Mater. Des. 47, 590–598 (2013).

I.-K. Kim and S. I. Hong, “Roll-bonded tri-layered Mg/Al/ stainless steel clad composites and their deformation and fracture behavior,” Metall. Mater. Trans. A 44, 3890–3900 (2013).

I.-K. Kim and S. I. Hong, “Effect of component layer thickness on the bending behaviors of roll-bonded trilayered Mg/Al/STS clad composites,” Mater. Des. 49, 935–944 (2013).

N. V. Govindaraj, J. G. Frydendahl, and B. Holmedal, “Layer continuity in accumulative roll bonding of dissimilar material combinations,” Mater. Des. 52, 905–915 (2013).

J. Y. Jin and S. I. Hong, “Effect of heat treatment on tensile deformation characteristics and properties of Al3003/STS439 clad composite,” Mater. Sci. Eng., A 596, 1–8 (2014).

D. V. Lazurenko, V. I. Mali, I. A. Bataev, A. Thoemmes, A. A. Bataev, A. I. Popelukh, A. G. Anisimov, and N. S. Belousova, “Metal-intermetallic laminate Ti–Al3Ti composites produced by spark plasma sintering of titanium and aluminum foils enclosed in titanium shells,” Metall. Mater. Trans. A 46, 4326–4334 (2015).

A. Y. Volkov, B. A. Greenberg, M. A. Ivanov, O. A. Elkina, A. V. Inozemtsev, A. V. Plotnikov, A. M. Patselov, and V. E. Kozhevnikov, “Electronmicroscopic examination of the transition zone of aluminum–tantalum bimetallic joints (Explosion welding),” Phys. Met. Metallogr. 115, 380–391 (2014).

V. V. Sagaradze, N. V. Kataeva, S. Yu. Mushnikova, O. A. Khar’kov, G. Yu. Kalinin, and V. D. Yampol’skii, “Structural transformations in hull material clad by nitrogen stainless steel using various methods,” Phys. Met. Metallogr. 115, 202–210 (2014).

I.-K. Kim and S. I. Hong, “Mechanochemical joining in cold roll-cladding of tri-layered Cu/Al/Cu composite and the interface cracking behavior,” Mater. Des. 57, 625–631 (2014).

J. S. Ha and S. I. Hong, “Design of high strength Cu alloy interlayer for mechanical bonding Ti to steel and characterization of their tri-layered clad,” Mater. Des. 51, 293–299 (2013).

E.-W. Jeong, K. N. Hui, and D.-H. Bae, “Identification of the intermetallic compound layer formed at the interface of roll-bonded aluminum-clad steel by thermal annealing,” Met. Mater. Int. 20, 499–502 (2014).

S. H. Kim, J. H. Kang, K. J. Euh, and H. W. Kim, “Grain-structure evolution of brazing-treated A4343/A3003/A4343 aluminum brazing sheets rolled with different reductions,” Met. Mater. Int. 21, 276–285 (2015).

S. E. Lee, K. S. Lee, M. J. Kim, and Y. N. Kwon, “Effect of thermal treatment on the interface-correlated mechanical properties of Al–Mg dissimilar metallic sheets,” Korean J. Met. Mater. 52, 605–613 (2014).

R. K. Islamgaliev, K. M. Nesterov, and R. Z. Valiev, “Structure, strength, and electric conductivity of a Cu–Cr copper-based alloy subjected to severe plastic deformation,” Phys. Met. Metallogr. 116, 209–218 (2015).

J. B. Correia, H. A. Davies, and C. M. Sellars, “Strengthening in rapidly solidified age hardened Cu–Cr and Cu–Cr–Zr alloys,” Acta Mater. 45, 177–190 (1997).

M. J. Saarivirta, “High conductivity copper-rich Cu–Zr alloys,” Trans. Metall. Soc. AIME 218, 431–437 (1960).

W. N. Kim and S. I. Hong, Mater. Sci. Eng., A 651, 976–986 (2016) http://dx.doi.org/ doi 10.1016/j.msea.2015.11.062

D. B. Butrymowicz, J. R. Manning, and M. E. Read, “Diffusion in copper and copper alloys,” J. Phys. Chem. Ref. Data 4, 177–249 (1975).

Z. Moser and L. A. Heldt, “The Cr–Zn (Chromium–Zinc) system,” J. Phase. Equilibr. 13, 172–176 (1992).

V. I. Zel’dovich, I. V. Khomskaya, N. Yu. Frolova, A. E. Kheifets, E. V. Shorokhov, and P. A. Nasonov, “Structure of chromium–zirconium bronze subjected to dynamic channel-angular pressing and aging,” Phys. Met. Metallogr. 114, 411–418 (2013).

I. S. Batra, G. K. Dey, U. D. Kulkarni, and S. Banerjee, “Precipitation in a Cu–Cr–Zr alloy,” Mater. Sci. Eng., A 356, 32–36 (2002).

M. J. Starink and X. M. Li, “A model for the electrical conductivity of peak aged and overaged Al–Zn–Mg–Cu alloys,” Metall. Mater. Trans. A 34, 899–911 (2003).

A. O. Olofinjanaa and K. S. Tan, “Achieving combined high strength and high conductivity in re-processed Cu–Cr alloy,” J. Achiev. Mater. Manufac. Eng. 35, 14–20 (2009).

S. I. Hong and M. A. Hill, “Microstructural stability and mechanical response of Cu–Ag microcomposite wires,” Acta Mater. 46, 4111–4122 (1998).

S. I. Hong and M. A. Hill, “Mechanical stability and electrical conductivity of Cu–Ag filamentary microcomposites,” Mater. Sci. Eng., A 264, 151–158 (1999).

J. D. Verhoeven, H. L. Downing, L. S. Chumbley, and E. D. Gibson, “The resistivity and microstructure of heavily drawn Cu–Nb alloys,” J. Appl. Phys. 65, 1293–1301 (1989).

J. S. Ha and S. I. Hong, “Deformation and fracture of Ti/439 stainless steel clad composite at intermediate temperatures, Mater. Sci. Eng, A 651, 805–809 (2016) http://dx.doi.org/10.1016/j.msea.2015.11.041

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Russian in Fizika Metallov i Metallovedenie, 2017, Vol. 118, No. 2, pp. 200–208.

The article is published in the original.

Rights and permissions

About this article

Cite this article

Kang, G.T., Song, J.S. & Hong, S.I. Effect of roll-bonding temperature on the strength and electrical conductivity of an α-brass-clad Cu–1Cr alloy composite. Phys. Metals Metallogr. 118, 190–197 (2017). https://doi.org/10.1134/S0031918X17020041

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X17020041