Abstract

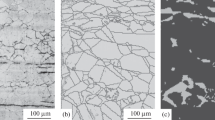

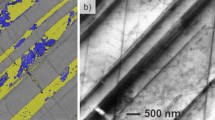

Using transmission electron microscopy, X-ray diffraction analysis, Mössbauer spectroscopy, microdurometry, and microindentation, the effect of large plastic deformations (through shear under pressure in Bridgman anvils) on the structure, phase composition, and micromechanical properties of high-nitrogen (1.24 wt % N) 08Kh22GA1.24 steel has been investigated. The steel was obtained by the casting method with counterpressure of nitrogen and was subjected to different heat treatments (quenching from1180°С, aging at 450 and 550°С) that form an austenitic (FCC) structure of the metallic matrix with chromium nitrides. It has been established that deformation by shear under pressure at room temperature results in the dispersion and deformation-induced partial dissolution of primary nitrides Cr2N in quenched and aged steel and in the complete (after aging at 450°С) and partial (after aging at 550°С) dissolution of secondary nitrides CrN. It has been noted that, for aged steel that contains finely dispersed secondary chromium nitrides upon shear deformation, as compared to the quenched state, the dispersion of the austenitic structure (down to nano- and submicrocrystalline states) is more intense and the enhancement in the microhardness and resistance to elastic–plastic deformations upon contact loading is more effective.

Similar content being viewed by others

References

Ts. Rashev, High-Nitrogen Steels. Metallurgy under Pressure (Bulgar. Acad. Sci., Sofia, 1995).

V. G. Gavriljuk and H. Berns, High Nitrogen Steels: Structure, Properties, Manufacture, Applications (Springer, Berlin, 1999).

H. Hanninen, J. Romu, R. Ilola, J. Tervo, and A. Laitinen, “Effects of processing and manufacturing of high nitrogen-containing stainless steels on their mechanical, corrosion and wear properties,” J. Mater. Proces. Technol. 117, 424–430 (2001).

O. A. Bannykh, “Economical stainless nitrogen steels: Promising substitutes for light alloys,” Metal. Sci. Heat Treat. 47, 261–265 (2005).

Ts. Rashev, “High nitrogen steels and metallurgy under pressure,” Trans. Indian Inst. Metals 55, 201–211 (2002).

L. Zhekova and Ts. Rashev, “Feasibility study on developing high-nitrogen steels by refining in suspended state under high pressure,” Metallurgist 51, 90–96 (2007).

L. G. Korshunov, Yu. N. Goikhenberg, N. A. Tereshchenko, A. I. Uvarov, A. V. Makarov, and N. L. Chernenko, “Wear resistance and surface structure of nitrogen-containing stainless austenitic steels upon friction and abrasive wear,” Phys. Met. Metallogr. 84, 554–561 (1997).

O. A. Bannykh, V. M. Blinov, M. V. Kostina, M. A. Filippov, M. S. Khadyev, Yu. R. Nemirovskii, and T. A. Belozerova, “On the interconnection of wear resistance with the phase composition and mechanical properties of new high-nitrogen iron-chromium alloys,” Metally, No. 2, 57–64 (2000).

A. V. Makarov, L. G. Korshunov, V. M. Schastlivtsev, N. L. Chernenko, and Yu. I. Filippov, “Structure and tribological and mechanical properties of high-chromium nitrogen-containing martensite-based steels,” Phys. Met. Metallogr. 96, 339–350 (2003).

J. C. Rawers, “Wear testing of high Fe–N–C Steels,” Wear 258, 32–39 (2005).

V. V. Berezovskaya, R. A. Savrai, E. A. Merkushkin, and A. V. Makarov, “Structure and mechanical and corrosion properties of new high-nitrogen CrMn steels containing molybdenum,” Russ. Metall. (Metally) 2012, 380–388 (2012).

E. S. Gorkunov, E. A. Putilova, S. M. Zadvorkin, A. V. Makarov, N. L. Pecherkina, G. Yu. Kalinin, S. Yu. Mushnikova, and O. V. Fomina, “Behavior of magnetic characteristics in promising nitrogen-containing steels upon elastoplastic deformation,” Phys. Met. Metallogr. 116, 838–849 (2015).

L. M. Kaputkina, V. G. Prokoshkina, and N. N. Krysina, “Structure and strain-induced martensitic transformations of carbon-containing and nitrogen-containing iron-based alloys,” Russ. Metall. (Metally) 2001, 628–632 (2001).

M. V. Kostina, A. V. Dymov, V. M. Blinov, and O. A. Bannykh, “Effect of plastic deformation on the structure and properties of Fe–Cr system,” Metal. Sci. Heat Treat. 44, 9–14 (2002).

V. A. Shabashov, S. V. Borisov, A. V. Litvinov, A. E. Zamatovskii, N. F. Vil’danova, V. I. Voronin, and O. P. Shepatkovskii, “Nanostructure formation and phase transformations in nitrided stainless steel Kh18N8 during severe cold deformation,” Phys. Met. Metallogr. 107, 601–612 (2009).

V. A. Shabashov, S. V. Borisov, A. V. Litvinov, V. V. Sagaradze, A. E. Zamatovskii, K. A. Lyashkov, and N. F. Vil’danova, “Deformation-induced cyclic phase transitions on dissolution–precipitation of nitrides in surface layers of Fe–Cr–(Ni)–N alloys,” Phys. Met. Metallogr. 113, 489–503 (2012).

G. A. Dorofeev, I. V. Sapegina, V. I. Lad’yanov, B. E. Pushkarev, E. A. Pechina, and D. V. Prokhorov, “Mechanical alloying and severe plastic deformation of nanocrystalline high-nitrogen stainless steels,” Phys. Met. Metallogr. 113, 963–973 (2012).

V. A. Shabashov, K. A. Kozlov, K. A. Lyashkov, N. V.Kataeva, A. V. Litvinov, V. V. Sagaradze, and A. E. Zamatovskii, “Solid-state mechanical synthesis of austenitic Fe–Ni–Cr–N alloys,” Phys. Met. Metallogr. 115, 392–402 (2014).

V. A. Shabashov, S. V. Borisov, A. V. Litvinov, N. V. Kataeva, S. V. Afanas’ev, and S. G. Titova, “Producing a gradient-composition nanocrystalline structure on nitrided surfaces of invar-type Fe–Ni alloys using megaplastic deformation,” Phys. Met. Metallogr. 115, 871–883 (2014).

E. S. Gorkunov, A. V. Makarov, S. M. Zadvorkin, A. L. Osintseva, S. Yu. Mitropol’skaya, S. V. Burov, R. A. Savrai, S. A. Rogovaya, Ts. Rashev, and L. Zhekova, “Electromagnetic control of composition, hardness, and wear-resistance of high-nitrogen stainless steels,” Defektoskopiya, No. 12, 19–30 (2012).

V. A. Teplov, V. P. Pilyugin, R. I. Kuznetsov, D. I. Tupitsa, V. A. Shabashov, and V. M. Gundyrev, “The bcc–fcc transition induced by deformation under pressure of an iron–nickel alloy,” Phys. Met. Metallogr. 64, 83–89 (1987).

V. S. Rusakov, Mössbauer Spectroscopy of Locally Inhomogeneous Systems (Almaty, 2000) [in Russian].

R. S. Reno and L. J. Swartzendruber, “Origin of Mössbauer linewidth in stainless steel,” in Proc. 18th Annu. Conf. Magn. Magn. Mater., Denver. Colo., 1972, Part 2 (New York, 1973), p. 1350.

V. A. Shabashov, L. G. Korshunov, V. V. Sagaradze, N. V. Kataeva, A. E. Zamatovskii, A. V. Litvinov, and K. A. Lyashkov, “Nitrogen distribution in austenitic high-nitrogen chromium-manganese steel under friction and high-pressure torsion,” Phys. Met. Metallogr. 114, 681–691 (2013).

B. P. Srivastava, H. N. K. Sarma, and D. L. Bhattacharya, “Ouadrupoles splitting in deformed stainless steel,” Phys. Stat. Sol, A 10, K117–K118 (1972).

K. Oda, K. Umezu, and H. Ino, “Interaction and arrangement of nitrogen atoms in fcc iron,” J. Phys.: Condens. Matter 2, 10147–10158 (1990).

R. M. Banov and G. Z. Zlateva, “Effect of nitrogen on concentration of stacking faults in Cr–Mn austenite,” Izv. Akad. Nauk SSSR, Met., No. 2, 172–176 (1977).

W. C. Oliver and J. M. Pharr, “An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments,” J. Mater. Res. 7, 1564–1583 (1992).

T. F. Page and S. V. Hainsworth, “Using nanoindentation techniques for the characterization of coated systems: A critique,” Surface Coat. Technol. 61, 201–208 (1993).

M. I. Petrzhik and E. A. Levashov, “Modern methods for investigating functional surfaces of advanced materials by mechanical contact testing,” Crystall. Rep. 52, 966–974 (2007).

Yu. R. Nemirovskii, M. S. Khadyev, M. A. Filippov, T. A. Belozerova, V. M. Blinov, M. V. Kostina, and A. V. Dymov, “Structure of Kh21A13 steel and phase transformations upon incomplete quenching of highnitrogen Fe–Cr steels,” Phys. Met. Metallogr. 93, 484–488 (2002).

Yu. I. Ustinovshchikov, A. V. Ruts, O. A. Bannykh, and V. M. Blinov, “Structure of high-nitrogen Fe–18%Cr alloys,” Metally, No. 1, 67–73 (1996).

Yu. I. Ustinovshchikov, O. A. Bannykh, V. M. Blinov, B. E. Pushkarev, M. V. Kostina, and A. V. Ruts, “Effect of heat treatment and the nitrogen content on the structure of Fe–Cr alloys,” Russ. Metall. (Metally) 2003, 263–268 (2003).

V. A. Shabashov, L. G. Korshunov, A. G. Mukoseev, V. V. Sagaradze, A. V. Makarov, V. P. Pilyugin, S. I. Novikov, and N. F. Vildanova, “Deformationinduced phase transitions in a high-carbon steel,” Mater. Sci. Eng., A 346, 196–207 (2003).

V. A. Shabashov, S. V. Borisov, A. E. Zamatovsky, N. F. Vildanova, A. G. Mukoseev, A. V. Litvinov, and O. P. Shepatkovsky, “Deformation-induced transformations in nitride layers formed in bcc iron,” Mater. Sci. Eng., A 452–453, 575–583 (2007).

W. C. Leslie and R. Z. Mieler, “The stabilization of austenite by closely spaced boundaries,” ASM Trans. Quart. 57, 972–979 (1964).

Y. T. Cheng and C. M. Cheng, “Relationships between hardness, elastic modulus and the work of indentation,” Appl. Phys. Lett. 73, 614–618 (1998).

P. H. Mayrhofer, C. Mitterer, and J. Musil, “Structure–property relationships in single- and dual-phase nanocrystalline hard coatings,” Surf. Coat. Technol. 174–175, 725–731 (2003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.V. Makarov, S.N. Luchko, V.A. Shabashov, E.G. Volkova, A.L. Osintseva, A.E. Zamatovskii, A.V. Litvinov, V.V. Sagaradze, 2017, published in Fizika Metallov i Metallovedenie, 2017, Vol. 118, No. 1, pp. 55–68.

Rights and permissions

About this article

Cite this article

Makarov, A.V., Luchko, S.N., Shabashov, V.A. et al. Structural and phase transformations and micromechanical properties of the high-nitrogen austenitic steel deformed by shear under pressure. Phys. Metals Metallogr. 118, 52–64 (2017). https://doi.org/10.1134/S0031918X17010045

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X17010045