Abstract

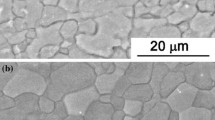

Methods of the severe plastic deformation (SPD) of pure magnesium at room temperature, namely, transverse extrusion and hydroextrusion in a self-destroyed shell, have been developed. The maximum true strain of the samples after the hydroextrusion was e ~ 3.2; in the course of transverse extrusion and subsequent cold rolling, a true strain of e ~ 6.0 was achieved. The structure and mechanical properties of the magnesium samples have been studied in different structural states. It has been shown that the SPD led to a decrease in the grain size d to ~2 μm; the relative elongation at fracture δ increased to ~20%. No active twinning has been revealed. The reasons for the high plasticity of magnesium after SPD according to the deformation modes suggested are discussed from the viewpoint of the hierarchy of the observed structural states.

Similar content being viewed by others

References

E. F. Amli, Foundations of Technology of Production and Treatment of Magnetic Alloys (Metallurgiya, Moscow, 1972) [in Russian].

T. G. Langdon, “Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement,” Acta Mater. 61, 7035–7059 (2013).

N. A. Kruglikov, Yu. N. Loginov, B. I. Kamenetskii, R. A. Savrai, A. V. Dolmatov, I. V. Klyukin, and A. Yu. Volkov, “Microstructure and mechanical properties of cast magnesium,” Liteishchik Rossii, No. 8, 17–21 (2013).

R. O. Kaibyshev and O. Sh. Sitdikov, “Structural changes during plastic deformation of pure magnesium,” Phys. Met. Metallogr. 73, 635–642 (1992).

R. O. Kaibyshev, O. Sh. Sitdikov, and A. M. Galiev, “Mechanisms of plastic deformation in magnesium: I. Deformation behavior of coarse-grained magnesium,” Phys. Met. Metallogr. 80, 354–360 (1995).

S. Biswas, S. S. Dhinwal, and S. Suwas, “Room-temperature equal channel angular extrusion of pure magnesium,” Acta Mater. 58, 3247–3261 (2010).

S. Mu, J. J. Jonas, and G. Gottstein, “Variant selection of primary, secondary and tertiary twins in a deformed Mg alloy,” Acta Mater. 60, 2043–2053 (2012).

J. Swiostek, J. Goken, D. Letzig, and K. U. Kainer, “Hydrostatic extrusion of commercial magnesium alloys at 100°C and its influence on grain refinement and mechanical properties,” Mater. Sci. Eng., A 424, 223–229 (2006).

N. B. Tork, N. Pardis, and R. Ebrahimi, “Investigation on the feasibility of room temperature plastic deformation of pure magnesium by simple shear extrusion process,” Mater. Sci. Eng., A 560, 34–39 (2013).

N. M. Shkatulyak, V. V. Usov, N. A. Volchok, A. A. Bryukhanov, S. V. San’kova, M. Rodman, M. Shaper, and C. Klose, “Effect of reverse bending on texture, structure, and mechanical properties of sheets of magnesium alloys with zinc and zirconium,” Phys. Met. Metallogr. 115, 609–614 (2014).

S. Suwas, G. Gottstein, and R. Kumar, “Evolution of crystallographic texture during equal channel angular extrusion (ECAE) and its effects on secondary processing of magnesium,” Mater. Sci. Eng., A 471, 1–14 (2007).

H. Kitahara, F. Maruno, M. Tsushida, and S. Ando, “Deformation behavior of Mg single crystals during a single ECAP pass at room temperature,” Mater. Sci. Eng., A 590, 274–280 (2014).

M. Efe, W. Moscoso, K. P. Trumble, W. D. Compton, and S. Chandrasekar, “Mechanics of large strain extrusion machining and application to deformation processing of magnesium alloys,” Acta Mater. 60, 2031–2042 (2012).

D. R. Nugmanov, O. Sh. Sitdikov, and M. V. Markushev, “Structure of magnesium alloy Ma14 after multistep isothermal forging and subsequent isothermal rolling,” Phys. Met. Metallogr. 116, 993–1001 (2015).

Mechanical Behavior of Materials under Pressure, Ed. by H. Pugh (Van Nostrand, Amsterdam, 1970; Mir, Moscow, 1973).

I. C. Choi, D. H. Lee, B. Ahn, K. Durst, M. Kawasaki, T. G. Langdon, and J. Jang, “Enhancement of strainrate sensitivity and shear yield strength of a magnesium alloy processed by high-pressure torsion,” Scr. Mater. 94, 44–47 (2015).

B. I. Kamenetskii, Yu. N. Loginov, and A. Yu. Volkov, “Methods and apparatus to increase plasticity of brittle materials upon cold upsetting with lateral support,” Zagotov. Proizvod. Mashinostr., No. 9, 17–23 (2013).

B. I. Kamenetskii, A. Yu. Volkov, A. L. Sokolov, O. V. Antonova, and I. V. Klyukin, “A method for producing magnesium foil,” RF Patent 2563077 (2014).

A. Yu. Volkov and I. V. Kliukin, “Improvement of the mechanical properties of pure magnesium through cold hydrostatic extrusion and low-temperature annealing,” Mater. Sci. Eng., A 627, 56–60 (2015).

N. V. Dudamell, I. Ulacia, F. Galvez, S. Yi, J. Bohlen, D. Letzig, I. Hurtado, and M. T. Perez-Prado, “Twinning and grain subdivision during dynamic deformation of a Mg AZ31 sheet alloy at room temperature,” Acta Mater. 59, 6949–6962 (2011).

T. Al-Samman, K. D. Molodov, D. A. Molodov, G. Gottstein, and S. Suwas, “Softening and dynamic recrystallization in magnesium single crystals during c-axis compression,” Acta Mater. 60, 537–545 (2012).

Y. Chino, K. Kimura, and M. Mabuchi, “Twinning behavior and deformation mechanisms of extruded AZ31 Mg alloy,” Mater. Sci. Eng., A 486, 481–488 (2008).

K. S. Raju, V. S. Sarma, A. Kauffmann, Z. Hegedus, J. Gubicza, M. Peterlechner, J. Freudenberger, and G. Wilde, “High strength and ductile ultrafine-grained Cu–Ag alloy through bimodal grain size, dislocation density and solute distribution,” Acta Mater. 61, 228–238 (2013).

O. V. Antonova, A. Yu. Volkov, B. I. Kamenetskii, D. A. Komkova, “Microstructure and mechanical properties of thin magnesium plates and foils obtained by lateral extrusion and rolling at room temperature,” Mater.Sci. Eng., A 651, 8–17 (2016).

W. M. Gan, M. Y. Zheng, H. Chang, X. J. Wang, X. G. Qiao, K. Wu, B. Schwebke, and H.-G. Brokmeier, “Microstructure and tensile properties of the ECAPed pure magnesium,” J. Alloys Compd. 470, 256–262 (2009).

I. R. Ahmad and D. W. Shu, “Compressive and constitutive analysis of AZ31B magnesium alloy over a wide range of strain rates,” Mater. Sci. Eng., A 592, 40–49 (2014).

R. Gehrmann, M. M. Frommert, and G. Gottstein, “Texture effects on plastic deformation of magnesium,” Mater. Sci. Eng., A 395, 338–349 (2005).

J. Bohlen, M. R. Nurnberg, J. W. Senn, D. Letzig, and S. R. Agnew, “The texture and anisotropy of magnesium–zinc–rare earth alloy sheets,” Acta Mater. 55, 2101–2112 (2007).

H. Somekawa and T. Mukai, “Effect of grain refinement on fracture toughness in extruded pure magnesium,” Scr. Mater. 53, 1059–1064 (2005).

N. Ono, R. Nowak, and S. Miura, “Effect of deformation temperature on Hall–Petch relationship registered for polycrystalline magnesium,” Mater. Lett. 58, 39–43 (2003).

H. J. Choi, Y. Kim, J. H. Shin, and D. H. Bae, “Deformation behavior of magnesium in the grain size spectrum from nanoto micrometer,” Mater. Sci. Eng., A 527, 1565–1570 (2010).

J. A. Sharon, Y. Zhang, F. Mompiou, M. Legros, and K. J. Hemker, “Discerning size effect strengthening in ultrafine-grained Mg thin films,” Scr. Mater. 75, 10–13 (2014).

Y. Wang and H. Choo, “Influence of texture on Hall–Petch relationships in an Mg alloy,” Acta Mater. 81, 83–97 (2014).

A. Yamashita, Z. Horita, and T. G. Langdon, “Improving the mechanical properties of magnesium and magnesium alloy through severe plastic deformation,” Mater. Sci. Eng., A 300, 142–147 (2001).

D. Sarker, J. Friedman, and D. L. Chen, “Influence of pre-deformation and subsequent annealing on strain hardening and anisotropy of AM30 magnesium alloy,” J. Alloys Compd. 611, 341–350 (2014).

R. O. Kaibyshev, O. Sh. Sitdikov, and A. M. Galiev, “Mechanisms of plastic deformation of magnesium. II. Analysis of activation processes,” Phys. Met. Metallogr. 80, 470–476 (1995).

G. C. Kaschner, C. N. Tome, R. J. McCabe, A. Misra, S. C. Vogel, and D. W. Brown, “Exploring the dislocation/twin interaction in zirconium,” Mater. Sci. Eng., A 463, 122–127 (2007).

H. Fan, S. Aubry, A. Arsenlis, and J. A. El-Awady, “Orientation influence on grain size effect in ultrafinegrained magnesium,” Scr. Mater. 97, 25–28 (2015).

Z. Keshavarz and M. R. Barnett, “EBSD analysis of deformation modes in Mg–3Al–1Zn,” Scr. Mater. 55, 915–918 (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.Yu. Volkov, O.V. Antonova, B.I. Kamenetskii, I.V. Klyukin, D.A. Komkova, B.D. Antonov, 2016, published in Fizika Metallov i Metallovedenie, 2016, Vol. 117, No. 5, pp. 538–548.

Rights and permissions

About this article

Cite this article

Volkov, A.Y., Antonova, O.V., Kamenetskii, B.I. et al. Production, structure, texture, and mechanical properties of severely deformed magnesium. Phys. Metals Metallogr. 117, 518–528 (2016). https://doi.org/10.1134/S0031918X16050161

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X16050161