Abstract

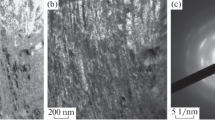

X-ray diffraction, electron microscopy, microhardness measurements, and differential scanning calorimetry have been used to investigate the formation of the dislocation substructure and nanocrystalline and amorphous structures in Ti-Ni shape-memory alloys depending on the degree of cold deformation by rolling and post-deformation annealing. The moderate deformation (e = 0.25) leads to the formation of a developed dislocation substructure; with an increase in the deformation to e = 2, the dislocation substructure is gradually substituted by a mixed nanocrystalline and amorphous structures. The residual martensite completely disappears as the deformation increases in the interval of e = 2−3 or upon annealing in the interval of 200–300°C. Annealing at 400°C after a moderate deformation leads to the formation of a polygonized (“nanosubgrain”) dislocation substructure in austenite. As the initial deformation increases to e = 2, this structure is gradually substituted by a nanocrystalline structure of austenite. Annealing after deformation to intermediate degrees (e = 0.75−1.0) results in the formation of a mixture of nanocrystalline and submicrocrystalline polygonized structures.

Similar content being viewed by others

References

S. D. Prokoshkin, V. Brailovski, I. Yu. Khmelevskaya, et al., “Creation of Substructure and Nanostructure in Thermomechanical Treatment and Control of Functional Properties of Ti-Ni Alloys with a Shape Memory Effect,” Metalloved. Term. Obrab. Met. No. 5, 24–29 (2005) [ Met. Sci. Heat Treat. 47 (5–6), 182–187 (2005)].

V. Brailovski, S. D. Prokoshkin, K. E. Inaekyan, et al., “Structure and Properties of the Ti-50.0 at % Ni Alloy after Strain Hardening and Nanocrystallizing Thermomechanical Processing,” Mater. Trans., JIM 47(3), 795–804 (2006).

S. D. Prokoshkin, V. Brailovski, K. E. Inaekyan, et al., “Structure and Properties of Severely Cold-Rolled and Annealed Ti-Ni Shape Memory Alloys,” Mater. Sci. Eng., A 481–482, 114–118 (2008).

V. Demers, V. Brailovski, S. Prokoshkin, and K. E. Inaekyan, “Thermomechanical Fatigue of Nanostructured Ti-Ni Shape Memory Alloys,” Mater. Sci. Eng., A 513–514, 185–196 (2009).

V. Demers, V. Brailovski, S. D. Prokoshkin, and K. E. Inaekyan, “Optimization of the Cold Rolling Processing for Continuous Manufacturing of Nanostructured Ti-Ni Shape Memory Alloys,” J. Mater. Process. Technol. 209(6), 3096–3105 (2009).

V. B. Fedorov, V. G. Kurdyumov, D. K. Khakimova, and E. V. Tat’yanin, “Effect of Grain Refinement during the Plastic Deformation of Titanium Nickelide,” Dokl. Akad. Nauk SSSR 269(4), 885–888 (1983).

J. Koike, D. M. Parkin, and M. Nastasi, “Crystal-to-Amorphous Transformation of NiTi Induced by Cold Rolling,” J. Mater. Res. 5(7), 1414–1418 (1990).

H. C. Lin and S. K. Wu, “The Effects of Cold Rolling on the Martensitic Transformation of Equiatomic Ti-Ni Alloy,” Acta Metall. Mater. 39(9), 2069–2080 (1991).

J. C. Ewert, I. Bohm, P. Peter, and F. Haider, “The Role of the Martensite Transformation for the Mechanical Amorphization of NiTi,” Acta Mater. 45(5), 2197–2206 (1997).

H. Nakayama, K. Tsuchiya, and M. Umemoto, “Crystal Refinement and Amorphization by Cold Rolling in TiNi Shape Memory Alloys,” Scr. Mater. 44(8-9), 1781–1785 (2001).

Y. Kim, G. Cho, S. Hur, et al., “Nanocrystallization of a Ti-50.0 Ni (at %) Alloy by Cold Working and Stress-Strain Behavior,” Mater. Sci. Eng., A 438–440, 531–535 (2006).

R. Z. Valiev, D. V. Gunderov, and V. G. Pushin, “The New SPD Processing Routes to Fabricate Bulk Nanostructured Materials,” in Proc. Int. Conf. Ultrafine Grained Materials IV, Ed. by Y. T. Zhu, T. G. Langdon, Z. Horita, et al., (TMS, Warrendale, Pa., 2006), pp. 105–112.

K. Tsuchiya, M. Inuzuka, D. Tomus, et al., “Martensitic Transformation in Nanostructured TiNi Shape Memory Alloy Formed via Severe Plastic Deformation,” Mater. Sci. Eng., A. 438–440, 643–648 (2006).

K. Tsuchiya, Y. Hada, M. Katahira, et al., “Properties of Amorphous/Nanocrystalline TiNi Wires,” in Proc. Int. Conf. SMST 2007, Ed. by S. Miyazaki (ASM International, Materials Park, Ohio, 2008), pp. 1–6.

E. V. Tat’yanin, V. G. Kurdyumov, and V.B. Fedorov, “Production of Amorphous Ti-Ni Alloys by Shear Deformation under Pressure,” Fiz. Met. Metalloved. 62(1), 133–137 (1986).

V. G. Pushin, L. I. Yurchenko, and T. G. Koroleva, “Formation of Nanocrystalline Structure in Bulk TiNi-Based Alloys with SME,” in Structure and Properties of Nanocrystalline Materials, Ed. by G. G. Taluts and N. I. Noskova (Ural. Otd. Ross. Akad. Nauk, Yekaterinburg, 1999), pp. 77–82 [in Russian].

V. G. Pushin, V. V. Stolyarov, R. Z. Valiev, et al., “Features of Structure and Phase Transformations in Shape Memory TiNi-Based Alloys after Severe Plastic Deformation,” Ann. Chim. Sci. Mat. 27(3), 77–88 (2002).

A. V. Sergueeva, C. Song, R. Z. Valiev, and A. K. Mukherjee, “Structure and Properties of Amorphous and Nanocrystalline NiTi Prepared by Severe Plastic Deformation and Annealing,” Mater. Sci. Eng., A 339, 159–165 (2003).

V. G. Pushin, D. V. Gunderov, N. I. Kourov, et al., “Nanostructures and Phase Transformations in TiNi Shape Memory Alloys Subjected to Severe Plastic Deformation,” in Proc. Int. Conf. Ultrafine Grained Materials III, Ed. by Y. T. Zhu, T. G. Langdon, R. Z. Valiev, et al. (TMS, Warrendale, Pa., 2004), pp. 481–486.

V. Brailovski, I. Yu. Khmelevskaya, S. D. Prokoshkin, et al., “Foundations of Heat and Thermomechanical Treatments and Their Effect on the Structure and Properties of Titanium Nickelide-Based Alloys,” Phys. Met. Metallogr. 97(Suppl. 1), 3–55 (2004).

S. D. Prokoshkin, I. Yu. Khmelevskaya, S. V. Dobatkin, et al., “Structure Evolution upon Severe Plastic Deformation of TiNi-Based Shape-Memory Alloys,” Fiz. Met. Metalloved. 97(6), 84–90 (2004) [Phys. Met. Metallogr. 97 (6), 619–625 (2004)].

S. D. Prokoshkin, I. Yu. Khmelevskaya, S. V. Dobatkin, et al., “Alloy Composition, Deformation Temperature, Pressure and Post-Deformation Annealing Effects in Severely Deformed Ti-Ni Based Shape Memory Alloys,” Acta Mater. 53, 2703–2714 (2005).

S. Chouf, M. Morin, S. Belkahla, and G. Guenin, “Equivalent Thermomechanical Treatments in an Equiatomic Ti-Ni Shape Memory Alloy,” Mater. Sci. Eng., A 438–440, 671–674 (2006).

I. I. Kornilov, N. F. Zhebyneva, S. V. Oleinikova, and L. P. Fatkullina, “Influence of Plastic Deformation on the Structure and Shape-Memory of Ti-54.8% Ni Alloy,” in Martensitic Transformations: Proc. Int. Conf. ICOMAT-77 (Naukova Dumka, Kiev, 1978), pp. 207–211 [in Russian].

S. D. Prokoshkin, A. V. Korotitskiy, V. Brailovski, and K. E. Inaekyan, “Effect of Dislocation Substructure and Grain Structure of B2-Austenite on Martensite Lattice Parameters and Transformation Lattice Strain in Binary Ti-Ni Alloys,” in Proc. Int. Conf. SMST 2007, Ed. by S. Miyazaki (ASM International, Materials Park, Ohio, 2008), pp. 63–70.

M. Piao, K. Otsuka, S. Miyazaki, and H. Horikawa, “Mechanism of the As Temperature Increase by Pre-Deformation in Thermoelastic Alloys,” Mater. Trans., JIM 34(10), 919–929 (1993).

S. D. Prokoshkin, S. Turenne, I. Yu. Khmelevskaya, et al., “Structural Mechanisms of High-Temperature Shape Changes in Titanium-Nickel Alloys after Low-Temperature Thermomechanical Treatment,” Can. Met. Q. 39(2), 225–234 (2000).

K. Otsuka and X. Ren, “Physical Metallurgy of Ti-Ni-Based Shape Memory Alloys,” Prog. Mater. Sci. 50, 511–678 (2005).

K. Inaekyan, V. Brailovski, S. Prokoshkin, et al., “Characterization of Amorphous and Nanocrystalline Ti-Ni-Based Shape Memory Alloys,” J. Alloys Compd. 473(1–2), 71–78 (2009).

K. H. J. Buschow, “Stability and Electrical Transport Properties of Amorphous Ti1 − x -Nix Alloys,” J. Phys. F: Met. Phys. 13(3), 563–571 (1983).

V. Brailovski, S. Prokoshkin, P. Terriault, et al., Shape Memory Alloys: Fundamentals, Modeling and Applications (ETS, Montreal, 2003).

V. I. Zel’dovich, N. Yu. Frolova, V. P. Pilyugin, et al., “Formation of Amorphous Structure in Titanium Nickelide under Plastic Deformation”, Fiz. Met. Metalloved. 99(4), 90–100 (2005) [Phys. Met. Metallogr. 99 (4), 425–434 (2005)].

Author information

Authors and Affiliations

Additional information

Original Russian Text © S.D. Prokoshkin, V. Brailovski, A.V. Korotitskiy, K.E. Inaekyan, A.M. Glezer, 2010, published in Fizika Metallov i Metallovedenie, 2010, Vol. 110, No. 3, pp. 305–320.

Rights and permissions

About this article

Cite this article

Prokoshkin, S.D., Brailovski, V., Korotitskiy, A.V. et al. Specific features of the formation of the microstructure of titanium nickelide upon thermomechanical treatment including cold plastic deformation to degrees from moderate to severe. Phys. Metals Metallogr. 110, 289–303 (2010). https://doi.org/10.1134/S0031918X10090127

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X10090127