Abstract

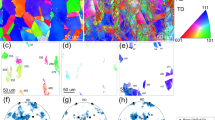

The method of automated analysis of electron backscatter diffraction (EBSD) patterns has been employed for the characterization of the structure of copper obtained using severe plastic deformation by shear under high pressure under cryogenic conditions. It has been established that severe cryogenic deformation leads to a considerable refinement of the structure to a grain size of 0.2 μm. Based on an analysis of the texture data and misorientation spectrum, it has been concluded that it is the 111<110> dislocation slip that was the main mechanism of plastic flow and that the contribution from twinning was very small. It has been shown that the evolution of the grain structure was mainly determined by elongation of initial grains in the direction of macroscopic shear and their subsequent fragmentation.

Similar content being viewed by others

References

H. Gleiter, “Nanocrystalline Materials,” Prog. Mater. Sci. 33, 223–315 (1989).

C. C. Koch and Y. S. Cho, “Nanocrystalls by High Energy Ball Milling,” Nanostruct. Mater. 1, 207–212 (1992).

R. Z. Valiev, “Ultrafine-Grained Materials Prepared by Severe Plastic Deformation: An Introduction,” Ann. Chim. Sci. Mater. 21, 369–378 (1996).

R. W. Siegel, Synthesis and Processing ofNanostructured Materials, in Mechanical Properties and Deformation Behavior of Materials Having Ultrafine Microstructures, NATO ASI Series, Series E: Applied Sciences, Vol. 233, Ed. by M. Nastasi, D. M. Parkin, and H. Gleiter (Kluwer, Dordrecht, 1993), p. 509–538.

I. D. Morokhov, L. D. Trusov, and V. I. Lapovok, Physical Phenomena in Ultradispersed Media (Energoatomizdat, Moscow, 1984) [in Russian].

H. Gleiter, “Nanosructured Materials: State of Art and Perspectives,” Nanostruct. Mater. 6, 3–14 (1995).

R. Z. Valiev and I. V. Aleksandrov, Nanostructured Materials Produced by Severe Plastic Deformation (Logos, Moscow, 2000) [in Russian].

V. M. Segal, V. I. Reznikov, V. I. Kopylov, et al., Processes of Plastic Structure Formation of Metals (Nauka i Tekhnika, Minsk, 1994) [in Russian].

G. A. Salishchev, O. R. Valiakhmetov, R. M. Galeev, et al. “Formation of Submicrocrystalline Structure in Titanium upon Plastic Deformation and Its Influence on Mechanical Properties,” Izv. Ross. Akad. Nauk, Met, No. 4, 86–91 (1996).

Ya. E. Beigel’zimer, V. N. Varyukhin, S. G. Synkov, et al., “New Techniques for Accumulating Large Plastic Deformations Using Hydroextrusion,” Fiz. Tekn. Vys. Davl. 9(3), 109–111 (1999).

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai, “Novel Ultra-High Straining Process for Bulk Materials—Development of the Accumulative Roll-Bonding (ARB) Process,” Acta Mater. 47, 579–583 (1999).

P. B. Prangnell, J. R. Bowen, and P. J. Apps, “Ultra-Fine Grain Structures in Aluminium Alloys by Severe Deformation Processing,” Mater. Sci. Eng., A 375–377, 178–185 (2004).

Y. Huang and P. B. Prangnell, “The Effect of Cryogenic Temperature and Change in Deformation Mode on the Limiting Grain Size in a Severely Deformed Dilute Aluminium Alloy,” Acta Mater. 56, 1619–1632 (2008).

Y. S. Li, N. R. Tao, and K. Lu, “Microstructural Evolution and Nanostructure Formation in Copper During Dynamic Plastic Deformation at Cryogenic Temperatures,” Acta Mater. 56, 230–241 (2008).

Y. Zhang, N. R. Tao, and K. Lu, “Mechanical Properties and Rolling Behaviors of Nano-Grained Copper with Embedded Nano-Twin Bundles,” Acta Mater. 56, 2429–2440 (2008).

V. P. Pilyugin, T. M. Gapontseva, T. I. Chashchukhina, et al., “Evolution of the Structure and Hardness of Nickel upon Cold and Low-Temperature Deformation under Pressure,” Fiz. Met. Metalloved. 105(4), 438–448 (2008) [Phys. Met. Metallogr. 105 (4), 409–418 (2008)].

T. M. Gapontseva, V. P. Pilyugin, L. M. Voronova, et al., “Evolution of the structure and hardness of cobalt upon cold and low-temperature deformation under pressure,” Deform. Razr. Mater. No. 8, 24–27 (2008).

F. J. Humphreys, “Characterisation of Fine-Scale Microstructures by Electron Backscatter Diffraction (EBSD),” Scr. Mater. 51, 771–776 (2004).

R. Z. Valiev, et al., “Bulk Nanostructured Materials from Severe Plastic Deformation,” Prog. Mater. Sci. 45, 103–189 (2000).

TexSEM Laboratories OIM Version 3.0, On-Line Help, Draper, UT: TSL, 2001.

J. K. Mackenzie, “Second Paper on Statistics Associated with the Random Disorientation of Cubes,” Biometrica 45(1–2), 229–240 (1958); “The Distribution of Rotation Angles in a Random Aggregate of Cubic Crystals,” Acta Metall. 2 (2), 224–234 (1964).

A. Gholinia, P. B. Prangnell, and M. V. Markushev, “The Effect of Strain Path on the Development of Deformation Structures in Severely Deformed Aluminium Alloys Processed by ECAE,” Acta Mater. 48, 1115–1130 (2000).

S. Li, I. J. Beyerlein, and M. A. M. Bourke, “Texture Formation during Equal Channel Angular Extrusion of FCC and BCC Metals: Comparison with Simple Shear,” Mater. Sci. Eng., A 394, 66–77 (2005).

Author information

Authors and Affiliations

Additional information

Original Russian Text © T.N. Kon’kova, S.Yu. Mironov, A.V. Korznikov, 2010, published in Fizika Metallov i Metallovedenie, 2010, Vol. 109, No. 2, pp. 184–189.

Rights and permissions

About this article

Cite this article

Kon’kova, T.N., Mironov, S.Y. & Korznikov, A.V. Severe cryogenic deformation of copper. Phys. Metals Metallogr. 109, 171–176 (2010). https://doi.org/10.1134/S0031918X10020092

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X10020092