Abstract

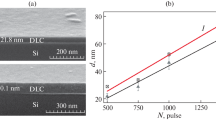

Diamond-like coatings (DLCs) have been obtained on a UVNIIPA-001 unit employing the method of pulse arc sputtering of a graphite target. DLCs of about 1.5 μm thick were applied onto substrates of the R6M5 steel. The relief of the coatings that were deposited using different temperature regimes has been studied. It has been established that a temperature rise of the surface of a growing DLC (condensation at a high frequency of arc pulses f) leads to the growth of films with numerous protrusions on their surface. The deposition of films at a low frequency f is more preferable to form smooth and hard DLCs under the conditions of unfiltered beam of carbon ions. The modification of the surface of diamond-like carbon coatings after their application has been investigated upon bombardment with accelerated ions of inert gas (argon) or chemically active oxygen. It has been established that the argon-ion bombardment is more preferable to smooth out the DLC relief. It has been shown that the relief of DLCs must be taken into account when measuring their microhardness, whereas the transformation of interatomic bonds in the near-surface layers after ion irradiation should be taken into consideration when analyzing the coatings by the methods whose informative depth is several monolayers.

Similar content being viewed by others

References

Y. Lifshitz, “Diamond-Like Carbon—Present Status,” Diamond Relat. Mater. 8, 1659–1676 (1999).

I. I. Aksenov and V. E. Strel’nitsky, “Synthesis of Hydrogen-Free Diamond-Like Coatings,” in Proceedings of ISFTE-12, Kharkov, Ukraine (Kharkov, 2001), pp. 96–103.

D. M. Sanders and A. Anders, “Review of Cathodic Arc Deposition Technology at the Start of the New Millennium,” Surf. Coating Technol. 133–134, 78–90 (2000).

M. I. Samoilovich and A. F. Belyanin, “Diamond and Diamond-Like Carbon Films: Formation and Structure,” in Diamond Films and Films of Related Materials. Proceedings of Kharkov Science Assembly ISFTF-15 (Kharkov, 2003), pp. 6–38.

A. B. Vladimirov, I. Sh. Trakhtenberg, O. M. Bakunin, et al., “The Effect of Substrate and DLC Morphology on the Tribological Properties Coating,” Diamond Relat. Mater. 9, 838–842 (2000).

V. N. Inkin, G. G. Kirpilenko, and A. J. Kolpakov, “Internal Stresses in Ta-C Films Deposited by Pulse Arc Discharge Method,” Diamond Relat. Mater. 10, 1103–1108 (2001).

V. E. Strel’nitskii, “Synthesis Processes and Physical Properties of Diamond-Like Carbon Coatings Obtained by Vacuum-Arc Method,” in Diamond Films and Films of Related Materials. Proceedings of Kharkov Science Assembly ISFTF-15 (Kharkov, 2003), pp. 104–115.

I. Sh. Trakhtenberg, A. B. Vladimirov, V. A. Yugov, et al., “Certification of Mechanical Properties of Hard Diamond-Like Coatings (DLC),” Fiz. Met. Metalloved. 99(6), 103–107 (2005) [Phys. Met. Metallogr. 99, 649–653 (2005)].

Y. Lifshitz, G. D. Lempert, E. Grossman, et al., “Growth Mechanisms of DLC Films from C+ Ions: Experimental Studies,” Diamond Relat. Mater. 4, 318–323 (1995).

A. B. Vladimirov, I. Sh. Trakhtenberg, S. A. Plotnilov, et al., “Modification of Amorphous DLC Films by Low Energy Ion Bombardment,” Diamond Relat. Mater. 5, 943–946 (1996).

S. Logothetidis, Ch. B. Lioutas, and M. Gioti, “Post-Growth Modification of Amorphous Carbon Films under Ion Beam Bombardment: Grain Size Dependence on the Film Thickness,” Diamond Relat. Mater. 7, 449–453 (1998).

I. Sh. Trakhtenberg, A. B. Vladimirov, A. P. Rubstein, et al., “The analysis of Microhardness Measurement Approach for Characterization of Hard Coatings,” Diamond Relat. Mater. 12, 1788–1792 (2003).

A. P. Dementjev, K. I. Maslakov, K. Uemura, et al., “Identification of Chemical Bonds on Upper Layers of DLC Using Auger Spectroscopy and XPS,” in Proceeding of ADC/FCT 2003 Conference (2003), pp. 345–349.

P. A. Arutyunov, A. L. Tolstikhina, and V. N. Demidov, “The Set of Parameters for Analysis of Roughness and Surface Microrelief of Materials in Scanning Probe Microscopy,” Zavod. Lab. 65(9), 27–37 (1999).

F. C. Ferrari, “Determination of Bonding in Diamond-Like Carbon by Raman Spectroscopy,” Diamond Relat. Mater. 11, 1053–1061 (2002).

I. Sh. Trakhtenberg, A. P. Rubshtein, and A. B. Vladimirov, “Formation of Morphology of Surface of Diamond-Like Films Condensed upon Arc Deposition of Graphite in a Vaccum”, Fiz. Met. Metalloved. 100(1), 65–70 (2005) [Phys. Met. Metallogr. 100, 56–60 (2005)].

A. V. Dvurechenskii, V. A. Zinoviev, et al. “Morphology and Reconstruction of Surface during Ge/Si Heteroepitaxy under Low-Energy Ion Beam,” in Proceeding of 11th International Conference on Radiation Physics and Chemistry of Condensed Matter, Tomsk, Russia (Tomsk, 2000), pp. 238–242.

M. Hakovirta, I. Koronen, R. Lappalainen, et al., “Protrusions on the Surface of Graphite Cathode Used in the Tetrahedral Amorphous Carbon Film Deposition,” Diamond Relat. Mater. 7, 23–35 (1998).

K. Yamamoto, K. Wazumi, T. Watanabe, et al., “Tribological Properties of Diamond-Like Carbon Films Prepared by Mass-Separated Ion Beam Deposition,” Diamond Relat. Mater. 11, 1130–1134 (2000).

Ye. L. Ostrovskaya and V. E. Strel’nitskij, “Effect of Micromechanical Properties of DLC Coatings on Their Frictional Behavior under Cryogenic Temperatures,” in Proceeding of 12th International Symposium ISTFE-12 (Kharkov, 2001), pp. 141–145.

J. F. Ziegler and J. P. Biersack, The Stopping Range of Ion in Solids (Pergamon, New York, 1985).

Author information

Authors and Affiliations

Additional information

Original Russian Text © A.P. Rubshtein, I.Sh. Trakhtenberg, V.A. Yugov, A.B. Vladimirov, S.A. Plotnikov, Yu.S. Ponosov, 2006, published in Fizika Metallov i Metallovedenie, 2006, Vol. 102, No. 6, pp. 671–677.

Rights and permissions

About this article

Cite this article

Rubshtein, A.P., Trakhtenberg, I.S., Yugov, V.A. et al. Temperature effect on the formation of a relief of diamond-like carbon coatings and its modification by ion bombardment. Phys. Metals Metallogr. 102, 626–631 (2006). https://doi.org/10.1134/S0031918X06120106

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X06120106