Abstract

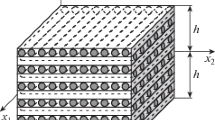

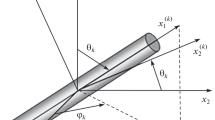

A refined model of viscoelastic-plastic deformation of flexible plates with spatial reinforcement structures has been developed. Strains of the composition materials are assumed to be small and decomposed into plastic and viscoelastic components. Instantaneous plastic deformation of these materials is described by the flow theory with isotropic hardening. Viscoelastic deformation obeys the governing equation of a linear model of a five-constant body. The geometric nonlinearity of the problem is taken into account in the Karman approximation. The possible weak resistance of the composite plates to lateral shear is modeled within the refined theory of bending, which makes it possible to determine (with varying degrees of accuracy) the displacements of plate points and the stress–strain state in the components of the composition. In the first approximation, relations corresponding to the conventional nonclassical Reddy theory follow from the obtained equations and boundary conditions. A numerical solution to the formulated initial-boundary-value problem is sought using an explicit “cross-type” scheme. The viscoelastic-plastic dynamic deformation of rectangular, relatively thin fiberglass plastic plates under explosive-type load is investigated. The plates have a conventional planar-cross (orthogonal) or spatial reinforcement structure. It is shown that, even in the case of relatively thin composite plates, the Reddy theory cannot be used for adequate calculation of their dynamic viscoelastic-plastic deformation. It is demonstrated that the value and shape of residual deflections depend not only on the structural reinforcement but also on the viscoelastic characteristics of the materials of composition components. It is found that a composite plate subjected to dynamic inelastic deformation may acquire a corrugated residual shape with longitudinally oriented folds. It is shown that, even for a relatively thin plate, replacement of the planar-cross reinforcement structure with a spatial structure decreases significantly the residual deflection and intensity of residual deformation in both binder material and some fiber families. For relatively thick plates, the effect of this replacement of reinforcing structures is even more pronounced.

Similar content being viewed by others

REFERENCES

Mouritz, A.P., Gellert, E., Burchill, P., and Challis, K., Review of advanced composite structures for naval ships and submarines, Compos. Struct., 2001, vol. 53, pp. 21–42. https://doi.org/10.1016/S0263-8223(00)00175-6

Soutis, C., Fibre reinforced composites in aircraft construction, Progr. Aero. Sci., 2005, vol. 41, pp. 143–151. https://doi.org/10.1016/j.paerosci.2005.02.004

Gibson, R.F., Principles of Composite Material Mechanics, 4th ed., Boca Raton: CRC, 2016. https://doi.org/10.1201/b19626

Gill, S.K., Gupta, M., and Satsangi, P.S., Prediction of cutting forces in machining of unidirectional glass fiber reinforced plastics composite, Front. Mech. Eng., 2013, vol. 8, pp. 187–200. https://doi.org/10.1007/s11465-013-0262-x

Solomonov, Yu.S., Georgievskii, V.P., Nedbai, A.Ya., and Andryushin, V.A., Prikladnye zadachi mekhaniki kompozitnykh tsilindricheskikh obolochek (Applied Problems of Mechanics of Composite Cylindrical Shells), Moscow, Fizmatlit, 2014.

Vasiliev, V.V. and Morozov, E., Advanced Mechanics of Composite Materials and Structural Elements, Amsterdam: Elsever, 2013. https://doi.org/10.1016/C2011-0-07135-1

Kazanci, Z., Dynamic response of composite sandwich plates subjected to time-dependent pressure pulses, Int. J. Non Lin. Mech., 2011, vol. 46, pp. 807–817. https://doi.org/10.1016/j.ijnonlinmec.2011.03.011

Morinière, F.D., Alderliesten, R.C., and Benedictus, R., Modelling of impact damage and dynamics in fibre-metal laminates: A review, Int. J. Impact Eng., 2014, vol. 67, pp. 27–38. https://doi.org/10.1016/j.ijimpeng.2014.01.004

Qatu, M.S., Sullivan, R.W., and Wang, W., Recent research advances on the dynamic analysis of composite shells: 2000–2009, Compos. Struct., 2010, vol. 93, pp. 14–31. https://doi.org/10.1016/j.compstruct.2010.05.014

Reddy, J.N., Mechanics of Laminated Composite Plates and Shells: Theory and Analysis, 2nd ed., Boca Raton: CRC, 2004.

Tarnopol'skiy, Yu.M., Zhigun, I.G., and Polyakov, V.A., Prostranstvenno-armirovannye kompozitsionnye materialy: Spravochnik (Spatially Reinforced Composite Materials, Reference Book), Moscow: Mashinostroenie, 1987,

Zhigun, I.G., Dushin, M.I., Polyakov, V.A., and Yakushin, V.A., Composites reinforced with a system of three straight mutually orthogonal fibers. 2. Experimental study, Polymer Mech., 1973, vol. 9, pp. 895–900. https://doi.org/10.1007/BF00856974

Mohamed, M.H., Bogdanovich, A.E., Dickinson, L.C., Singletary, J.N., and Lienhart, R.R., A new generation of 3D woven fabric performs and composites, SAMPE J., 2001, vol. 37, no. 3, pp. 3–17.

Schuster, J., Heider, D., Sharp, K., and Glowania, M., Measuring and modeling the thermal conductivities of three-dimensionally woven fabric composites, Mech. Compos. Mater., 2009, vol. 45, pp. 165–174. https://doi.org/10.1007/s11029-009-9072-y

Tarnopol’skii, Yu.M., Polyakov, V.A., and Zhigun, I.G., Composite materials reinforced with a system of three straight, mutually orthogonal fibers. I. Calculation of the elastic characteristics, Polymer Mech., 1973, vol. 9, pp. 754–759. https://doi.org/10.1007/BF00856271

Kregers, A.F. and Teters, G.A., Structural model of deformation of anisotropic, spatially reinforced composites, Mekh. Kompoz. Mater., 1982, no. 1, pp. 14–22.

Yankovskii, A.P., Determination of the thermoelastic characteristics of spatially reinforced fibrous media in the case of general anisotropy of their components. 1. Structural model, Mech. Compos. Mater., 2010, vol. 46, no. 5, pp. 451–460. https://doi.org/10.1007/s11029-010-9162-x

Yankovskii, A.P., Elastic-plastic deformation of flexible plates with spatial reinforcement structures, J. Appl. Mech. Tech. Phys., 2018, vol. 59, pp. 1058–1066. https://doi.org/10.1134/S0021894418060111

Yankovskii, A.P., Modelling the viscoelastic-plastic deformation of flexible reinforced plates with account of weak resistance to transverse shear, Vychisl. Mekh. Splosh. Sred, 2019, vol. 12, no. 1, pp. 80–97. https://doi.org/10.7242/1999-6691/2019.12.1.8

Paimushin, V.N., Firsov, V.A., Gyunal, I., and Egorov, A.G., Theoretical-experimental method for determining the parameters of damping based on the study of damped flexural vibrations of test specimens. 1. Experimental basis, Mech. Compos. Mater., 2014, vol. 50, pp. 127–136. https://doi.org/10.1007/s11029-014-9400-8

Bogdanovich, A.E., Nelineinye zadachi dinamiki tsilindricheskikh kompozitnykh obolochek (Nonlinear Problems of the Dynamics of Cylindrical Composite Shells), Riga: Zinatne, 1987.

Abrosimov, N.A. and Bazhenov, V.G., Nelineinye zadachi dinamiki kompozitnykh konstruktsii (Nonlinear Problems of Dynamics Composites Designs), Nizhniy Novgorod: Nizhegor. Gos. Univ., 2002.

Reissner, E., The effect of transverse-shear deformation on the bending of elastic plates, J. Appl. Mech., 1945, vol. 12, no. 2, pp. 69–77.

Mindlin, R.D., Thickness-shear and flexural vibrations of crystal plates, J. Appl. Phys., 1951, vol. 22, no. 3, pp. 316–323.

Andreev, A., Uprugost’ i termouprugost’ sloistykh kompozitnykh obolochek. Matematicheskaya model’ i nekotorye aspekty chislennogo analiza (Elasticity and Thermo-Elasticity Layered Composite Shells. Mathematical Model and Some Aspects of the Numerical Analysis), Saarbrücken, Deutschland: Palmarium Academic, 2013.

Kulikov, G.M., Thermoelasticity of flexible multilayer anisotropic shells, Mech. Solids, 1994, vol. 29, no. 2, pp. 27–35.

Whitney, J.M. and Sun, C.T., A higher order theory for extensional motion of laminated composites, J. Sound Vibr., 1973, vol. 30, pp. 85–97. https://doi.org/10.1016/S0022-460X(73)80052-5

Pikul’, V.V., Mekhanika obolochek (Mechanics of Shells), Vladivostok: Dal’nauka, 2009.

Yankovskii, A.P., Modeling of elastoplastic deformation of flexible shallow shells with spatial reinforcement structures, Vychisl. Mekh. Splosh. Sred, 2018, vol. 11, no. 3, pp. 335–354. https://doi.org/10.7242/1999-6691/2018.11.3.25

Ivanov, G.V., Volchkov, Yu.M., Bogul’skiy, I.O., Anisimov, S.A., and Kurguzov, V.D., Chislennoe reshenie dinamicheskikh zadach uprugoplasticheskogo deformirovaniya tverdykh tel (Numerical Solution of Dynamic Problems of Elastoplastic Deformation of Solids), Novosibirsk: Sib. Univ., 2002.

Houlston, R. and DesRochers, C.G., Nonlinear structural response of ship panels subjected to air blast loading, Comput. Struct., 1987, vol. 26, nos. 1–2, pp. 1–15. https://doi.org/10.1016/0045-7949(87)90232-X

Zeinkiewicz, O.C. and Taylor, R.L., The Finite Element Method, Vol. 1: The Basis, Oxford: Butterworth-Heinemann, 2000.

Handbook of Physics, Vol. 6: Elasticity and Plasticity, Flügge, S., Ed., Berlin: Springer, 1958. https://doi.org/10.1007/978-3-662-43081-1

Kolarov, D., Baltov, A., and Boncheva, N., Mekhanika plasticheskikh sred (Mechanics of Plastic Media), Moscow: Mir, 1979.

Kachanov, L.M., Osnovy teorii plastichnosti (Bases of the Theory of Plasticity), Moscow: Nauka, 1969.

Naghdi, P.M. and Murch, S.A., On the mechanical behavior of viscoelastic/plastic solids, J. Appl. Mech., 1963, vol. 30, no. 3, pp. 321–328. https://doi.org/10.1115/1.3636556

Paimushin, V.N., Firsov, V.A., Gyunal, I., Egorov, A.G., and Kayumov, R.A., Theoretical-experimental method for determining the parameters of damping based on the study of damped flexural vibrations of test specimens. 3. Identification of the characteristics of internal damping, Mech. Compos. Mater., 2014, vol. 50, pp. 633–646. https://doi.org/10.1007/s11029-014-9451-x

Rabotnov, Yu.N., Polzuchest’ elementov konstruktsii (Creep of Structural Elements), 3th ed., Moscow: LENAND, 2019.

Khazhinskiy, G.M., Modeli deformirovaniya i razrusheniya metallov (Model of Deformation and Fracture of Metals), Moscow: Nauchnyi Mir, 2011.

Malmeyster, A.K., Tamuzh, V.P., and Teters, G.A., Soprotivlenie zhestkikh polimernykh materialov (Resistance of Rigid Polymeric Materials), Riga: Zinatne, 1972.

Kompozitsionnye materialy. Spravochnik (Composite Materials. Reference Book), Karpinos, D.M., Ed., Kiev: Naukova Dumka, 1985.

Handbook of Composites, Lubin, G., Ed., New York: Van Nostrand Reinhold, 1982.

Funding

This work was supported by the Program of Fundamental Research of State Academies of Sciences for 2017–2020 (project no. 23.4.1: “Mechanics of Deformation and Destruction of Materials and Media under Mechanical Loads, in Physical Fields, and in Chemically Active Media”).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Yu. Sin’kov

Rights and permissions

About this article

Cite this article

Yankovskii, A.P. A Refined Model of Viscoelastic-Plastic Deformation of Flexible Plates with Spatial Reinforcement Structures. J Appl Mech Tech Phy 62, 1045–1062 (2021). https://doi.org/10.1134/S0021894421070208

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894421070208