Abstract

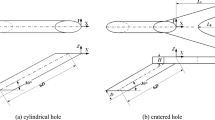

The present study deals with the flow field and cooling performance for flat-plate cylindrical film cooling holes embedded in contoured craters, especially considering the effect of the crater depth. A. test matrix of the crater depth ranging from 0.25 to 1.25 times of the cylindrical hole diameter and the blowing ratio ranging from 0.5 to 2.0 is used in CFD computations. The numerical results show that the flow fields downstream from the hole exit can be altered significantly due to interaction between the ejected coolant and contoured crater. The cooling performance depends on both the specific crater depth and blowing ratio; however, the cratered hole is always superior to the cylindrical hole in terms of the area-averaged cooling effectiveness regardless of the crater depth and blowing ratio. The cratered hole with a. crater depth equal to the hole diameter is recommended.

Similar content being viewed by others

References

D. G. Bogard and K. A. Thole, “Gas Turbine Film Cooling,” J. Propuls. Power 22 (2), 249–270 (2006).

R. S. Bunker, “Film Cooling: Breaking the Limits of Diffusion Shaped Holes,” Heat Transfer Res. 41 (6), 627–650 (2010).

R. S. Bunker, “Film Cooling Effectiveness due to Discrete Holes with a. Transverse Surface Slot,” ASME Paper No. GT2002-30178 (2002).

M. A. Pakhomov, V. I. Terekhov, A. A. Khalatov, and I. I. Borisov, “Film Cooling Effectiveness with Injection Through Circular Holes Embedded in a. Transverse Trench,” Thermophys. Aeromech. 22 (3), 329–337 (2015).

T. Pric and R. Campbell, “Method for Improving the Cooling Effectiveness of a. Gaseous Coolant Stream which Flows Through a. Substrate, and Related Articles of Manufacture,” US Patent No. 6383602, MKI F. 01 D. 5/08, Publ. 7.05.2002.

J. R. Dorrington, D. G. Bogard, and R. S. Bunker, “Film Effectiveness Performance for Coolant Holes Embedded in Various Shallow Trench and Crater Depressions,” ASME Paper No. GT2007-27992 (2007).

F. T. Davidson, J. E. Dees, and D. G. Bogard, “An Experimental Study of Thermal Barrier Coatings and Film Cooling on an Internally Cooled Simulated Turbine Vane,” ASME Paper No. GT2011-46604 (2011).

N. Tran, C. Nguyen, S. Ho, et al., “Prediction of Adiabatic Effectiveness of Various Cratered Film Hole Configurations. Pt 1. Sensitivity Analysis for the Rectangle Shaped Mask,” AIAA Paper No. 2010-0404 (2010)

Y. Lu, A. Dhungel, S. V. Ekkad, and J. Kapat, “Film Cooling Measurement for Cratered Cylindrical Inclined Holes,” J. Turbomach. 131 (2), 011005 (2009).

J. H. Kim and K. Y. Kim, “Surrogate-Based Optimization of a. Cratered Cylindrical Hole to Enhance Film-Cooling Effectiveness,” J. Thermal Sci. Technol. 11 (2), JTST0025 (2016).

A. A. Khalatov, N. A. Panchenko, and S. D. Severin, “Application of Cylindrical, Triangular and Hemispherical Dimples in the Film Cooling Technology,” J. Phys.: Conf. Ser. 891, 012145 (2017).

A. A. Khalatov, N. A. Panchenko, and S. D. Severin, “Flat Plate Film Cooling at the Coolant Supply into Triangular and Cylindrical Craters,” MATEC Web Conf. 115, 09003 (2017).

P. Kalghatgi and S. Acharya, “Improved Film Cooling with a. Round Film Cooling Hole Embedded in a. Contoured Crater,” J. Turbomach. 137 (10), 101006 (2015).

B. T. An, J. J. Liu, X. D. Zhang, et al., “Film Cooling Effectiveness Measurements of a. Near Surface Streamwise Diffusion Hole,” Int. J. Heat Mass Transfer. 103, 1–13 (2016).

L. C. Bai and C. Zhang, “Flow Mechanism of Cooling Effectiveness Improvement for the Cylindrical Film Cooling Hole with Contoured Craters,” IOP Conf., Ser. Mater. Sci. Eng. 473 (1), 012033 (2019).

R. S. Bunker, “The Effects of Manufacturing Tolerances on Gas Turbine Cooling,” J. Turbomach. 131 (4), 041018 (2009).

F. T. Davidson, D. A. Kistenmacher, and D. G. Bogard, “Film Cooling with a. Thermal Barrier Coating: Round, Holes, Craters and Trenches,” ASME Paper No. GT2012-70029 (2012).

Y. Lu, A. Dhungel, S. V. Ekkad, et al., “Effect of Trench width and Depth on Film Cooling from Cylindrical Holes Embedded in Trenches,” J. Turbomach. 131 (2), 011003 (2009).

K. D. Lee and K. Y. Kim, “Film Cooling Performance of Cylindrical Holes Embedded in a. Transverse Trench,” Numer. Heat Transf., A. 65, 127–143 (2014).

C. Zhang and Z. Wang, “Effect of the Downstream Crescent-Shaped Block Height on the Flat-Plate Film Flow and Cooling Performance,” J. Appl. Mech. Tech. Phys. 59 (5), 951–961 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © J.L. Fu, L.C. Bai, C. Zhang, P.F. Ju.

__________

Translated from Prikladnaya Mekhanika i Tekhnicheskaya Fizika, Vol. 60, No. 6, pp. 107–117, November- December, 2019.

Rights and permissions

About this article

Cite this article

Fu, J.L., Bai, L.C., Zhang, C. et al. Film Cooling Performance for Cylindrical Holes Embedded in Contoured Craters: Effect of the Crater Depth. J Appl Mech Tech Phy 60, 1068–1076 (2019). https://doi.org/10.1134/S0021894419060129

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894419060129