Abstract

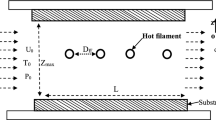

This paper presents a method for the analytical calculation of the flow velocity of the gas mixture and the concentration of the growth component during vapor-phase epitaxy in a reaction chamber with a rotating substrate holder disk. The concentration of the growth component is analyzed in relation to some epitaxy process parameters.

Similar content being viewed by others

References

Molecular Beam Epitaxy and Heterostructures, Ed. by L. Cheng and K. Plog (Martinus Nijhoff, Dordrecht, 1985).

M. A. Herman, W. Richter, and H. Sitter, Epitaxy-Physical Principles and Technical Implementation (Springer, Berlin, 2004).

G. B. Stringfellow, Organometallic Vapor-Phase Epitaxy: Theory and Practice (Academic Press, Boston, 1989).

P. B. Boldyrevsky, A. G. Korovinm S. A. Denisov, et al., “Homogeneity of the Thicknesses of Silicon Layers Grown from a Sublimation Source by Molecular Beam Epitaxy,” Zh. Tekh. Fiz. 84 (11), 155–158 (2014).

P. B. Boldyrevskii and O. I. Khrykin, “Effect of Transients in the Gas Phase on the Electrical Properties of Submicron Structures Obtained by Organometallic Chemical Vapor Deposition,” Izv. Akad. Nauk SSSR, Neorg. Mater. 26 (10), 2215–2217 (1990).

I. A. Frolov, P. B. Boldyrevskii, B. L. Druz’, and E. B. Sokolov, “Mechanism of Epitaxial Growth of GaAs,” Izv. Akad. Nauk SSSR, Neorg. Mater. 13 (5), 773–775 (1977).

R. A. Talalaev, E. V. Yakovleva, S. Yu. Karpova, and Yu. N. Makarov, “On Low Temperature Kinetic Effects in Metal–Organic Vapor Phase Epitaxy of III–V Compounds,” J. Cryst. Growth. 230, 232–238 (2001).

V. V. Lundin, A. V. Sakharov, E. E. Zavarin, et al., “Effect of the Carrier Gas and Doping Profile on the Surface Morphology of Heavily Doped GaN:Mg Layers Grown by Organometallic Vapor-Phase Epitaxy,” Fiz. Tekh. Poluprovod. 43 (7), 996–1001 (2009).

V. G. Levich, Physicochemical Hydrodynamics (Nauka, Moscow, 1962) [in Russian].

G. A. Korn and T. M. Korn, Mathematical Handbook for Scientists and Engineers (Dover, New York, 2000).

E. L. Pankratov, “Decreasing of Depth of p-n-Junction in a Semiconductor Heterostructure by Serial Radiation Processing and Microwave Annealing,” J. Comput. Theor. Nanosci. 9, 41–49 (2012).

E. L. Pankratov and E. A. Bulaeva, “About Controlling of Regimes of Heating during Growth a Heterostructures from Gas Phase,” Universal J. Mater. Sci. 1, 180–200 (2013).

Yu. D. Sokolov, “Determination of Dynamic Forces in Mine Lifting Cables,” Prikl. Mekh. 1 (1), 23–35 (1955).

A. Yu. Luchka, Theory and Application of the Method of Averaging Functional Corrections (Izd. Akad. Nauk USSR, Kiev, 1963) [in Russian].

P. Zhanh, H. Wei, G. Cong, et al., “Effects of Disk Rotation Rate on the Growth of ZnO Films by Low-Pressure Metal–Organic Vapor Deposition,” Thin Solid Films 516, 925–928 (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Prikladnaya Mekhanika i Tekhnicheskaya Fizika, Vol. 57, No. 4, pp. 74–83, July–August, 2016.

Rights and permissions

About this article

Cite this article

Pankratov, E.L., Boldyrevskii, P.B. Convective diffusion from a gas phase to a rotating disk. J Appl Mech Tech Phy 57, 637–645 (2016). https://doi.org/10.1134/S0021894416040076

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894416040076