Abstract—

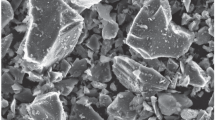

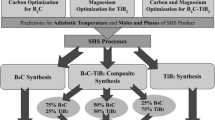

We have studied the effect of mechanical activation in a ball mill on the properties of titanium and boron powders, combustion parameters, and characteristics of consolidated titanium diboride (TiB2) ceramics. Using forced self-propagating high-temperature synthesis compaction, we have prepared a ceramic material with a relative density of 95% and hardness HV = 28.3 GPa.

Similar content being viewed by others

REFERENCES

Samsonov, G.V., Markovskii, L.Ya., Zhigach, A.F., and Valyashko, M.G., Bor, ego soedineniya i splavy (Boron, Its Compounds, and Its Alloys), Kiev: Akad. Nauk Ukr. SSR, 1960.

Kieffer, R. and Benesovsky, F., Hartmetalle, Vienna: Springer, 1965.

Svoistva, poluchenie i primenenie tugoplavkikh soedinenii (Properties, Preparation, and Applications of Refractory Compounds), Kosolapova, T.Ya., Ed., Moscow: Metallurgiya, 1986.

Weimin Wang, Zhengyi Fu, Hao Wang, and Runzhang Yuan, Influence of hot-pressing sintering temperature and time on microstructure and mechanical properties of TiB2 ceramics, J. Eur. Ceram. Soc., 2002, vol. 22, pp. 1045–1049.

Urbanovich, V.S., Kopylov, A.V., and Kukareko, V.A., Physicomechanical properties of high-pressure-sintered titanium diboride powder, Fiz. Tekh. Vys. Davlenii, 2011, vol. 21, no. 4, pp. 77–85.

Bhaumik, S.K., Divakar, C., Singh, A.K., and Upadhyaya, G.S., Synthesis and sintering of TiB2 and TiB2–TiC composite under high pressure, Mater. Sci. Eng., 2000, vol. 279, nos. 1–2, pp. 275–281.

Schmidt, J., Boehling, M., Burkhardt, U., and Grin, Y., Preparation of titanium diboride TiB2 by spark plasma sintering at slow heating rate, Sci. Technol. Adv. Mater., 2007, no. 8, pp. 376–382.

Merzhanov, A.G., Tverdoplamennoe gorenie (Solid Flame Combustion), Chernogolovka: ISMAN, 2000.

Pityulin, A.N., Forced compaction in self-propagating high-temperature synthesis processes, Sbornik nauchnykh statei. Samorasprostranyayushchiisya vysokotemperaturnyi sintez: teoriya i praktika (A Collection of Scientific Papers: Self-Propagating High-Temperature Synthesis: Theory and Practice), Chernogolovka: Territoriya, 2001.

Bogatov, Yu.V., Levashov, E.A., Blinova, T.V., and Pityulin, A.N., Technological aspects of the preparation of compact titanium diboride by self-propagating high-temperature synthesis, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 1985, no. 3, pp. 51–55.

Bogatov, Yu.V., Barinov, V.Yu., and Shcherbakov, V.A., Effect of titanium powder morphology on self-propagating high-temperature synthesis parameters and the structure of compact titanium diboride, Perspekt. Mater., 2020, no. 3, pp. 50–60.https://doi.org/10.30791/1028-978X-2020-3-50-60

Bogatov, Yu.V. and Shcherbakov, V.A., Influence of Ti and B powder mixing modes on mixture properties and SHS composite microstructure, Russ. J. Non-Ferrous Met., 2021, vol. 62, no. 2, pp. 248–256.https://doi.org/10.3103/S1067821221020036

Levashov, E.A., Kurbatkina, V.V., and Kolesnichenko, K.V., General aspects of the effect of mechanical preactivation on the reactivity of titanium-based self-propagating high-temperature synthesis mixtures, Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 2000, no. 6, pp. 61–67.

Kochetov, N.A. and Vadchenko, S.G., Effect of the time of mechanical activation of a Ti + 2B mixture on combustion of cylindrical samples and thin foils, Combust. Explos. Shock Waves, 2015, vol. 51, pp. 467–471.

Bogatov, Yu.V. and Shcherbakov, V.A., Forced SHS compaction of Ti–B blends: influence of mixing conditions and sample mass, Int. J. Self-Propag. High-Temp. Synth., 2020, vol. 29, no. 2, pp. 100–103.https://doi.org/10.3103/S106138622002003X

Chernyavskii, K.S., Stereologiya v metallovedenii (Stereology in Metallurgy Science), Moscow: Metallurgiya, 1977.

Kiparisov, S.S. and Libenson, G.A., Poroshkovaya metallurgiya (Powder Metallurgy), Moscow: Metallurgiya, 1980.

Makarov, Yu.I., Apparaty dlya smesheniya sypuchikh materialov (Apparatuses for Mixing Free-Flowing Materials), Moscow: Mashinostroenie, 1973.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Bogatov, Y.V., Shcherbakov, V.A. & Boyarchenko, O.D. Preparation of Dense TiB2 by Forced Self-Propagating High-Temperature Synthesis Compaction with Mechanical Activation of Reagents. Inorg Mater 57, 1061–1066 (2021). https://doi.org/10.1134/S0020168521100010

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168521100010