Abstract—

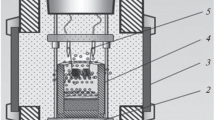

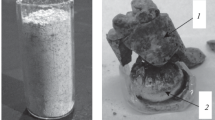

We have studied the spontaneous comminution of cast materials consisting of a Mn-doped Cr2AlC MAX phase and chromium, manganese, and aluminum carbides and aluminides. The materials were prepared in the form of ingots by self-propagating high-temperature synthesis (SHS) in a 3-L reactor at an argon pressure p = 5 MPa. The starting mixtures consisted of manganese(IV) oxide, chromium(III) oxide, aluminum (ASD-1), and carbon. The presence of aluminum carbide (Al4C3) in a cast material has been shown to lead to spontaneous comminution of the cast material (without mechanical or chemical influences) into powders with a crystalline particle size under 100 μm. The particle size reduction has been shown to result from reaction between aluminum carbide and atmospheric moisture. The synthesized materials have been characterized by X-ray diffraction and X-ray microanalysis, and we have studied structural and phase states of particles of the desired products obtained as a result of self-comminution of a cast SHS material.

Similar content being viewed by others

REFERENCES

Guilemagy, J.M., Espallargas, N., Suegama, P.H., and Benedetti, A.V., Comparative study of Cr3C2–NiCr coating, Corros. Sci., 2006, vol. 48, no. 10, pp. 2998–3013.https://doi.org/10.1016/j.corsci.2005.10.016

Burkhanov, G.S., Milyaev, I.M., and Yusupov, V.S., Current status and development trends in hard-magnetic materials, Perspekt. Mater., 2011, no. 11, pp. 208–215.

Alymov, M.I., Milyaev, I.M., Nurislamov, A.Kh., and Yusupov, V.S., Hard magnetic alloys based on the Mn–Al system, Tsvetn. Met., 2015, no. 1, pp. 91–96.

Barsoum, M.W., The MAX phases: a new class of solids: thermodynamically stable nanolaminates, Prog. Solid State Chem., 2000, vol. 28, pp. 201–281.https://doi.org/10.1016/S0079-6786(00)00006-6

Tian, W.B., Wang, P.L., Zhang, G., Kan, Y., Li, Y., and Yan, D., Synthesis and thermal and electrical properties of bulk Cr2AlC, Scr. Mater., 2006, vol. 54, pp. 841–846.https://doi.org/10.1016/j.scriptamat.2005.11.009

Lin, Z., Zhou, Y., and Li, M., Synthesis, microstructure, and property of Cr2AlC, J. Mater. Sci. Technol., 2007, vol. 23, no. 6, pp. 721–746.

Schneider, J.M., Sun, Z., Mertens, R., Uestel, F., and Ahuja, R., Ab-initio calculations and experimental determination of the structure of Cr2AlC, Solid State Commun., 2004, vol. 130, no. 7, pp. 445–449.https://doi.org/10.1016/j.ssc.2004.02.047

Lin, S., Huang, Y., Zu, L., Kan, X., Lin, J., Song, W., Tong, P., Zhu, X., and Sun, Y., Alloying effects on structural, magnetic and electric/thermal transport properties in MAX phase Cr2 – xMxGeC (M = Ti, V, Mn, Fe and Mo), J. Alloys Compd., 2016, vol. 680, pp. 452–461.https://doi.org/10.1016/j.jallcom.2016.04.197

Hamm, C.M., Bocarsly, J.D., Seward, G., Kramm, U.I., and Birke, C.S., Non-conventional synthesis and magnetic properties of MAX phases (Cr/Mn)2AlC and (Cr/Fe)2AlC, J. Mater. Chem. C, 2017, vol. 5, no. 23, pp. 5700–5708.https://doi.org/10.1039/C7TC00112F

Tian, W., Vanmeensel, K., Wang, P., Zhang, G., Li, Y., Vleugels, J., and Biest, O., Synthesis and characterization of Cr2AlC ceramics prepared by spark plasma sintering, Mater. Lett., 2007, vol. 61, pp. 4442–4445.

Xiao, Li.O., Li, S.B., Song, G., and Sloof, W.G., Synthesis and thermal stability of Cr2AlC, J. Eur. Ceram. Soc., 2011, vol. 31, pp. 1497–1502.

Levashov, E.A., Mukasyan, A.S., Rogachev, A.S., and Shtansky, D.V., Self-propagating high-temperature synthesis of advanced materials and coatings, Int. Mater. Rev., 2017, vol. 62, no. 4, pp. 203–239.https://doi.org/10.1080/09506608.2016.1243291

Gorshkov, V.A., Miloserdov, P.A., Luginina, M.A., Sachkova, N.V., and Belikova, A.F., High-temperature synthesis of a cast material with a maximum content of the MAX phase Cr2AlC, Inorg. Mater., 2017, vol. 53, no. 3, pp. 271–277.https://doi.org/10.1134/S0020168517030062

Gorshkov, V.A., Miloserdov, P.A., Sachkova, N.V., Luginina, M.A., and Yukhvid, V.I., SHS metallurgy of Cr2AlC MAX phase-based cast materials, Russ. J. Non-Ferrous Met., 2018, vol. 59, no. 5, pp. 570–575.https://doi.org/10.3103/S106782121805005X

Rebinder, P.A. and Shchukin, E.D., Surface effects in deformation and fracture of solids, Usp. Fiz. Nauk, 1972, vol. 108, no. 1, pp. 26–36.

Gorshkov, V.A., Miloserdov, P.A., Ignat’eva, T.I., Semenova, V.N., and Kovalev, I.D., AlON powders by aluminothermic SHS under pressure: synthesis and characterization, Int. J. Self-Propag. High-Temp. Synth., 2017, vol. 26, no. 4, pp. 240–243.

Ignat’eva, T.I., Miloserdova, O.M., Semenova, V.N., and Borovinskaya, I.P., Chemical particle size reduction as a means of obtaining ultrafine and nanocrystalline titanium carbide powders, Perspekt. Mater., 2009, no. 3, pp. 82–87.

Ignat’eva, T.I., Barinova, T.V., Semenova, V.N., and Barinov, V.Yu., Leaching of Si3N4 powders from self-propagating high-temperature synthesis products: effect of the process on particle morphology and size, Mezhdunarodn. Zh. Prikl. Fundam. Issled., 2017, no. 11-1, pp. 135–139.

Ordan’yan, S.S., Nesmelov, D.D., and Ovsienko, A.I., Phase formation during reaction sintering of B4C–SiC–Si(Al) composites, Novye Ogneupory, 2017, no. 12, pp. 42–48. https://doi.org/https://doi.org/10.17073/1683-4518-2017-12-42-48

Laipeng Yan, Zhanqiu Tan, Gang Li, Genlian Fan, Schryvers, D., Aidang Shan, and Di Zhang, A quantitative method to characterize the Al4C3-formed interfacial reaction: the case study of MWCNT/Al composites, Mater. Character., 2016, vol. 112, pp. 213–216.https://doi.org/10.1016/j.matchar.2015.12.031

Hihara, L.H., Corrosion of aluminum-matrix composites, Corros. Rev., 1997, vol. 15, pp. 361–386.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Gorshkov, V.A., Khomenko, N.Y. & Sachkova, N.V. Comminution of Cast Materials Prepared by Self-Propagating High-Temperature Synthesis in the Mn–Cr–Al–C System. Inorg Mater 57, 586–591 (2021). https://doi.org/10.1134/S0020168521060029

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168521060029