Abstract—

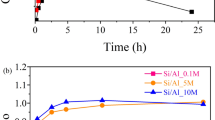

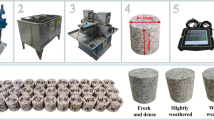

We have studied the effect of the phase composition of clinoptilolite rocks and the specific mechanical energy delivered to samples in a vibratory attritor on their physical properties and oil sorption capacity. Mechanical activation in air has been shown to cause amorphization, transformation of “zeolitic” water into “hydroxyl” water, and an electron density redistribution in the Al–O–Si framework of the clinoptilolite. Milling to a specific mechanical energy of 2.16 kJ/g leads to the formation of molecularly dense aggregates, which shows up as a decrease in specific surface area, demonstrated by BET measurements. An optimal approach for raising oil sorption capacity is mechanical activation of clinoptilolite–stilbite rock in air to a specific mechanical energy of 5.04 kJ/g.

Similar content being viewed by others

REFERENCES

Breck, D.W., Zeolite Molecular Sieves: Structure, Chemistry, and Use, Breck, D.W., Ed., New York: Wiley, 1974.

Kussainova, M.Zh., Jussipbekov, U.Z., and Pas, S., Structural investigation of raw clinoptilolite over the Pb2+ adsorption process from phosphoric acid, J. Mol. Struct., 2019, vol. 1184, pp. 49–58.

Obuzdina, M.V. and Rush, E.A., Sorption characteristics of modified zeolites studied by infrared and energy dispersive X-ray spectroscopy techniques, Vestn. Tekhnol. Univ., 2019, vol. 22, no. 3, pp. 2–29.

Kazemi, M. and Falamaki, C., Study on the kinetics and mechanism of the catalytic oxidation reaction of Mn2+ using clinoptilolite supported δ-MnO2 nanocatalyst, Proc. Saf. Environ. Prot., Part B, 2015, vol. 94, no. 100, pp. 65–71.

Nikashina, V.A., Streletsky, A.N., Kolbanev, I.V., Meshkova, I.V., Grinev, V.G., Serova, I.B., Yusupov, T.S., and Shumskaya, L.G., Effect of mechanical activation on the properties of natural zeolites, Inorg. Mater., 2011, vol. 47, no. 12, pp. 1341–1346.https://doi.org/10.1134/S0020168511120144

Morozova, N.N. and Kais, Kh.A., Improving the reactivity of zeolite-containing cements by mechanical activation, Vestn. Tekhnol. Univ., 2016, vol. 19, no. 14, pp. 79–82.

Bebiya, A.G., Gulyaev, P.Yu., and Milyukova, I.V., Effect of specific surface area of particles on sorption characteristics of zeolites occurring at different levels, Vestn. Yugorsk. Gos. Univ., 2014, no. 2 (33), pp. 15–23.

Bohács, K., Faitli, J., Bokányi, L., and Mucsi, G., Control of natural zeolite properties by mechanical activation in stirred media mill, Arch. Metall. Mater., 2017, vol. 62, no. 2B, pp. 1399–1406. https://doi.org/10.1515/amm-2017-0216

Avvakumov, E.G., Mekhanicheskie metody aktivatsii khimicheskikh protsessov (Mechanical Methods for Activation of Chemical Processes), Novosibirsk: Nauka, 1986.

Butyagin, P.Yu. and Pavlichev, I.K., Determination of energy yield of mechanochemical reactions, React. Solids, 1986, vol. 1, pp. 361–365.

Davydova, M.L. and Shadrinov, N.V., Polymer–elastomer nanocomposites based on butadiene nitrile rubber, ultra high molecular weight polyethylene, and a natural zeolite, Perspekt. Mater., 2010, no. 9, pp. 283–288.

Juhasz, A.Z. and Opoczky, L., Mechanical Activation of Minerals by Grinding Pulverizing and Morphology of Particles, New York: Halsted, 1990.

Jha, V.K. and Hayashi, S., Modification on natural clinoptilolite zeolite for its \({\text{NH}}_{{\text{4}}}^{{\text{ + }}}\) retention capacity, J. Hazard. Mater., 2009, no. 169, pp. 29–35.https://doi.org/10.1016/j.jhazmat.2009.03.052

Bochács, K., Kristály, F., and Mucsi, G., The influence of mechanical activation of the nanostructure of zeolite, J. Mater. Sci., 2018, vol. 53, no. 19, pp. 13779–13789.https://doi.org/10.1007/s10853-018-2502-2

Bandura, L., Panek, R., and Franus, W., The use of clinoptilolite and synthetic zeolites for removal of petroleum substances, Visn. Nats. Univ. L’vivs. Politekh., 2014, no. 781, pp. 9–16.

Koval’, L.M., Korobitsina, L.L., and Vosmerikov, A.V., Sintez, fiziko-khimicheskie i kataliticheskie svoistva vysokokremnezemnykh tseolitov (Synthesis, Physicochemical Properties of High-Silica Zeolites), Tomsk: Tomsk. Gos. Univ., 2001.

Eremin, I.S., Development of a sugarcane-based sorbent, Ekol. Prom–st. Ross., 2017, vol. 21, no. 10, pp. 14–17.

Khodakov, G.S., Physicochemical mechanics of technological processes for materials processing, Ross. Khim. Zh., 2000, vol. 44, no. 3, pp. 93–107.

Sirotkina, E.E. and Novoselova, L.Yu., Materials for adsorption of crude oil and derivatives from water, Khim. Interesah Ustoich. Razvit., 2005, vol. 13, pp. 359–377.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dabizha, O.N., Derbeneva, T.V., Khamova, T.V. et al. Controlling the Sorption Activity of Clinoptilolites with Mechanical Activation. Inorg Mater 57, 399–408 (2021). https://doi.org/10.1134/S0020168521040038

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168521040038