Abstract—

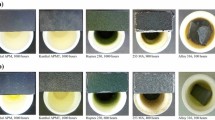

A process has been developed for the fabrication of double-layer silica ceramic crucibles with a composite inner layer containing 25 wt % boron nitride. We have studied the wettability of the container material by molten germanium in an argon atmosphere at a temperature of 1000°C. The contact angle has been determined to be 128°, exceeding that of BN-free silica ceramics by ~8°. The work of adhesion evaluated from the contact angle is 0.25 J/m2.

Similar content being viewed by others

REFERENCES

Dimroth, F. and Kurtz, S., High-efficiency multijunction solar cells, MRS Bull., 2007, vol. 32, no. 3, pp. 230–235.https://doi.org/10.1557/mrs2007.27

Taishi, T., Ise, H., and Murao, Y., Czochralski-growth of germanium crystals containing high concentrations of oxygen impurities, J. Cryst. Growth, 2010, vol. 312, no. 19, pp. 2783–2787.https://doi.org/10.1016/j.jcrysgro.2010.05.045

Luque, A. and Hegedus, S., Handbook of Photovoltaic Science and Engineering, Chichester: Wiley, 2003.

Claeys, L. and Simoen, E., Germanium-Based Technologies: from Materials to Devices, Oxford: Elsevier, 2007.

Hubbard, G.S., Haller, E.E., and Hansen, W.L., Zone refining high-purity germanium, IEEE Trans. Nucl. Sci., 1978, vol. 25, no. 1, pp. 362–370.https://doi.org/10.1109/TNS.1978.4329333

Depuydt, B., Theuwis, A., and Romandic, I., Germanium: from the first application of Czochralski crystal growth to large diameter dislocation-free wafers, Mater. Sci. Semicond. Proc., 2006, vol. 9, no. 4, pp. 437–443.https://doi.org/10.1016/j.mssp.2006.08.002

Podkopaev, O.I., Shimanskii, A.F., Kulakovskaya, T.V., Gorodishcheva, A.N., and Golubovskaya, N.O., Amorphous silica containers for germanium ultrapurification by zone refining, Inorg. Mater., 2016, vol. 52, no. 11, pp. 1091–1095.https://doi.org/10.7868/S0002337X16100122

Rajput, R.K., Basic Electrical and Electronics Engineering, New Delhi: Laxmi, 2005.

Heraeus Conamic – Backbone of the Information Age, Heraeus Holding GmbH. https://www.heraeus.com/en/hqs/fused_silica/home_hqs.aspx

Shimanskii, A.F., Pivinskii, Yu.E., Savchenko, N.S., and Podkopaev, O.I., RF Patent 2333900, 2008.

Kaiser, N., Cröll, A., Szofran, F.R., Cobb, S.D., and Benz, K.W., Wetting angle and surface tension of germanium melts on different substrate materials, J. Cryst. Growth, 2001, vol. 231, no. 4, pp. 448–457.https://doi.org/10.1016/S0022-0248(01)01480-4

Cröll, A., Salk, N., Szofran, F.R., Cobb, S.D., and Volz, M.P., Wetting angles and surface tension of Ge1 – xSix melts on different substrate materials, J. Cryst. Growth, 2002, vol. 242, pp. 45–54.https://doi.org/10.1016/S0022-0248(02)01347-7

Cröll, A., Lantzsch, R., Kitanov, S., Salk, N., Szofran, F.R., and Tegetmeier, A., Melt–crucible wetting behavior in semiconductor melt growth systems, Cryst. Res. Technol., 2003, vol. 38, pp. 669–675.https://doi.org/10.1002/crat.200310081

Malmqvist, J. and Tegman, R., Boron nitride coated ceramic crucible with a hole in the bottom—a new device replacing expensive crucibles for the preparation of fusion bead samples for X-ray fluorescence analysis, Anal. Commun, 1997, vol. 34, pp. 343–350.https://doi.org/10.1039/A706796H

Shimanskii, A.F., Podshibyakina, E.Yu., Vasil’eva, M.N., Kulakovskaya, T.V., and Pavlyuk, T.O., RF Patent 2688705, 2019.

Suzdal’tsev, V.I. and Borodai, F.Ya., USSR Inventor’s Certificate no. 501052, 1976.

ACKNOWLEDGMENTS

In this study, we used equipment at the Krasnoyarsk Regional Shared Research Facilities Center, Krasnoyarsk Scientific Center (Federal Research Center), Siberian Branch, Russian Academy of Sciences.

Funding

This work was supported by the Russian Federation Ministry of Science and Higher Education as part of the state research target for the Siberian Federal University federal state autonomous educational institution of higher education, project no. FSRZ-2020-0013.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Shimanskii, A.F., Podshibyakina, E.Y., Samoilo, A.S. et al. Silica Crucibles for Molten Germanium with a Boron Nitride-Containing Composite Inner Layer. Inorg Mater 57, 208–212 (2021). https://doi.org/10.1134/S0020168521020114

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168521020114