Abstract

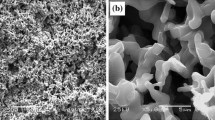

We have studied characteristic structural features of porous TiNi-based materials prepared by diffusion sintering and containing titanium additions. The results demonstrate that increasing the percentage of added titanium reduces the porosity coefficient of the material and increases the volume fraction of Ti2Ni and Ti4Ni2(O,N,C) secondary phases. It has been shown that the addition of titanium powder can be used for correcting the atomic composition of TiNi.

Similar content being viewed by others

REFERENCES

Sysolyatin, P.G., Sysolyatin, S.P., Baidik, O.D., et al., History f the development of jaw joint surgery, Byull. Sib. Med., 2016, vol. 15, no. 2, pp. 98–111.https://doi.org/10.20538/1682-0363-2016-2-98-111

Radkevich, A.A., Gyunter, V.E., Sinyuk, I.V., et al., Osteosynthesis of mandibular fractures using titanium nickelide structures, Mire Nauchn.Otkrytii, 2018, vol. 10, no. 5, pp. 12–27.https://doi.org/10.12731/wsd-2018-5-12-27

Lanshakov, V.A., Gyunter, V.E., Panov, A.A., et al., Operativnoe lechenie perelomov kostnykh tkanei s ispol’zovaniem implantatov s pamyat’yu formy (Surgical Treatment of Bone Tissue Fractures Using Shape Memory Implants), Tomsk: MITs, 2016.

Kul’bakin, D.E., Choinzonov, E.L., Mukhamedov, M.R., et al., Reconstructive and plastic surgery in combined treatment of locally advanced tumors of the head and neck, Vopr. Onkol., 2017, vol. 63, no. 6, pp. 862–866.

Radkevich, A., Gantimurov, A., Zhiglov, N., et al., Application of TiNi dental implants with permeable porosity in patients rehabilitation with different adentia options, J. Mater. Sci., 2017, vol. 2, no. 1, pp. 211–218.https://doi.org/10.18502/kms.v2i1.799

Yuan, B., Zhu, M., and Chung, C.Y., Biomedical porous shape memory alloys for hard-tissue replacement materials, Materials, 2018, vol. 11, paper 1716.https://doi.org/10.3390/ma11091716

Gyunter, V.E., Khodorenko, V.N., Chekalkin, T.L., et al., Meditsinskie materialy i implantaty s pamyat’yu formy (Medical Shape Memory Materials and Implants), vol. 1: Meditsinskie materialy s pamyat’yu formy (Medical Shape Memory Materials), Tomsk: MITs, 2011.

Resnina, N., Belyaev, S., Voronkov, A., et al., Mechanical behavior and functional properties of porous Ti–45 at. % Ni alloy produced by self-propagating high-temperature synthesis, Smart Mater. Struct., 2016, vol. 25, no. 5, paper 055018.https://doi.org/10.1088/0964-1726/25/5/055018

Kasimtsev, A.V., Markova, G.V., Shuitsev, A.V., et al., Change in structure during consolidation of calcium hydride powders of TiNi intermetallic, Metallurgist, 2015, vol. 58, nos. 11–12, pp. 1038–1045.https://doi.org/10.1007/s11015-015-0037-1

Anikeev, S., Hodorenko, V., Chekalkin, T., et al., Fabrication and study of double sintered TiNi-based porous alloys, Smart Mater. Struct., 2017, vol. 26, no. 5, paper 057001.https://doi.org/10.1088/1361-665X/aa681a

Drozdov, I.A., Structure formation of titanium nickelide in powder metallurgy processes, Doctoral (Phys.–Math.) Dissertation, 1998.

Andrievskii, R.A., Poroshkovoe materialovedenie (Powder Materials Research), Moscow: Metallurgiya, 1991.

Anikeev, S.G., Artyukhova, N.V., Khodorenko, V.N., et al., Structural features of TiNi-based biocompatible porous materials with terraced pore-wall surface morphology, Russ. Phys. J., 2018, vol. 61, nos. 3–4, pp. 1039–1046.https://doi.org/10.1007/s11182-018-1494-3

Belyaev, S.P., Gil’mutdinov, F.Z., and Kanunnikova, O.M., Oxidation and segregation processes on the surface of titanium nickelide, Pis’ma Zh. Tekh. Fiz., 1999, vol. 25, no. 13, pp. 89–94.

Baggerly, R.G., Electrolytic phase extraction: an old technique to evaluate precipitates in nitinol, Adv.X-Ray Anal., 2012, vol. 55, pp. 80–88.https://doi.org/10.1017/S0885715612000279

Sheng, L., Yang, Y., Xi, T., et al., Effect of heat treatment on morphology evolution of Ti2Ni phase in Ti–Ni–Al–Zr alloy, IOP Conf. Ser.: Mater. Sci. Eng., 2018, vol. 322, paper 022040.https://doi.org/10.1088/1757-899X/322/2/022040

Otsuka, K. and Ren, X., Physical metallurgy of Ti–Ni-based shape memory alloys, Prog. Mater. Sci., 2005, vol. 50, no. 5, pp. 511–678.https://doi.org/10.1016/j.pmatsci.2004.10.001

Anikeev, S.G., Garin, A.S., Artyukhova, N.V., et al., Structural and morphological features of TiNi-based powder manufactured by the method of hybrid-calcium reduction, Russ. Phys. J., 2018, vol. T. 61, no. 4, pp. 749–756.https://doi.org/10.1007/s11182-018-1456-9

Klopotov, A.A., Potekaev, A.I., Kozlov, E.V., et al., Kristallogeometricheskie i kristallokhimicheskie zakonomernosti obrazovaniya binarnykh i troinykh soedinenii na osnove titana i nikelya (Crystal-Geometric and Crystal-Chemical General Relationships Governing the Formation of Titanium- and Nickel-Based Binary and Ternary Compounds), Tomsk: Tomsk. Politekh. Univ., 2011.

Gupta, R.K., Anil Kumar, V., and Khanra, G.P., Reactive and liquid-phase sintering techniques, in Intermetallic Matrix Composites, 2018, pp. 303–318.https://doi.org/10.1016/B978-0-85709-346-2.00011-X

Zhang, J., Liu, Y., Ren, Y., et al., In situ synchrotron x-ray diffraction study of deformation behavior and load transfer in a Ti2Ni–NiTi composite, Appl. Phys. Lett., 2014, vol. 105, no. 4, paper 041910.https://doi.org/10.1063/1.4892352

Peng, W., Liu, K., Shah, B.A., et al., Enhanced internal friction and specific strength of porous TiNi shape memory alloy composite by the synergistic effect of pore and Ti2Ni, J. Alloys Compd., 2019, vol. 816, paper 152578.https://doi.org/10.1016/j.jallcom.2019.152578

Yang, B., Luo, Z., Yuan, B., et al., High damping of lightweight TiNi–Ti2Ni shape memory composites for wide temperature range usage, J. Mater. Eng. Perform., 2017, vol. 26, no. 10, pp. 4970–4976.https://doi.org/10.1007/s11665-017-2947-5

Funding

This work was supported by the Russian Science Foundation, project no. 19-79-10045.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Anikeev, S.G., Kaftaranova, M.I., Khodorenko, V.N. et al. Effect of Titanium Additions on Structural Aspects of Porous TiNi-Based Materials Prepared by Diffusion Sintering. Inorg Mater 56, 918–923 (2020). https://doi.org/10.1134/S0020168520090022

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168520090022