Abstract

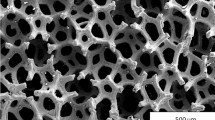

A simple method for the preparation of a foam glass/CoFe2O4 composite material has been proposed for the first time. We have demonstrated the conceptual feasibility of utilizing glass scrap and plant ash and slag for the preparation of cellular glassy materials suitable for use as supports of catalytically active substances. The synthesized composite materials have been characterized by X-ray diffraction and electrode microscopy. A possible mechanism of cobalt(II) ferrite structure formation on the surface of foam glass has been discussed. We have studied the photocatalytic properties of the synthesized materials for the oxidative destruction of an organic dye in the presence of hydrogen peroxide. The synthesized support has been shown to be inert in the catalytic process studied. The foam glass/CoFe2O4 composite material exhibits high catalytic activity under the conditions studied here: complete removal of the organic dye from a solution takes 210 min after the reaction onset.

Similar content being viewed by others

REFERENCES

Fedorov, V.A., Potolokov, N.A., Menshchikova, T.K., and Brekhovskikh, M.N., Physicochemical aspects of the preparation of high-purity arsenic-containing substances from various raw materials, Inorg. Mater., 2017, vol. 53, no. 10, pp. 1024–1032.https://doi.org/10.1134/S0020168517100053

Fedorov, V.A., Potolokov, N.A., Menshchikova, T.K., and Brekhovskikh, M.N., Hydride process for the preparation of high-purity arsenic, Inorg. Mater., 2018, vol. 54, no. 10, pp. 1033–1038.https://doi.org/10.1134/S0020168518100060

Nikiforova, E.M., Eromasov, R.G., Vasil’eva, M.N., and Simonova, N.S., Recycling of Sorsk MPP molybdenum ore flotation waste in the fabrication of cellular heat-insulating structural ceramics, Obogashch. Rud, 2017, no. 1 (367), pp. 40–45. https://doi.org/10.17580/or.2017.01.08

Yatsenko, E.A., Gol’tsman, B.M., Kosarev, A.S., Karandashova, N.S., Smolii, V.A., and Yatsenko, L.A., Synthesis of foamed glass based on slag and a glycerol pore-forming mixture, Glass. Phys. Chem., 2018, vol. 44, no. 2, pp. 152–155.

Praxedes, F.M., Teixeira, J.V.U., Luz, P.T.S., Fernandez, O.J.C., Figueira, B.A.M., and Araujo, S.M.S.D., Use of industrial residues for production of cellular glasses of low environmental impact, Mater. Res. Express, 2019, vol. 6, paper 065513.

Da Silva, R.C., Kubaski, E.T., Tenorio-Neto, E.T., Lima-Tenorio, M.K., and Tebcherani, S.M., Foam glass using sodium hydroxide as foaming agent: study on the reaction mechanism in soda–lime glass matrix, J. Non-Cryst. Solids, 2019, vol. 511, pp. 177–182.

Sener, T., Kayhan, E., Sevim, M., and Metin, Ö., Monodisperse CoFe2O4 nanoparticles supported on Vulcan XC-72: high performance electrode materials for lithium–air and lithium-ion batteries, J. Power Sources, 2015, vol. 288, pp. 36–41.

Liu, X., Wu, N., Cui, C., Zhou, P., and Sun, Y., Enhanced rate capability and cycling stability of core/shell structured CoFe2O4/onion-like C nanocapsules for lithium-ion battery anodes, J. Alloys Compd., 2015, vol. 644, pp. 59–65.

Li, M.R., Song, C., Wu, Y., Wang, M., Pan, Z.P., Sun, Y., Meng, L., Han, S.G., Xu, L.J., and Gan, L., Novel Z‑scheme visible-light photocatalyst based on CoFe2O4/BiOBr/graphene composites for organic dye degradation and Cr(VI) reduction, Appl. Surf. Sci., 2019, vol. 478, pp. 744–753.

Heidari, M.R., Varma, R.S., Ahmadian, M., Pourkhosravani, M., Asadzadeh, S.N., Karimi, P., and Khatami, M., Photo-fenton like catalyst system: activated carbon/CoFe2O4 nanocomposite for reactive dye removal from textile wastewater, Appl. Sci.-Basel, 2019, vol. 9, no. 5, paper 963.

Sun, M.J., Han, X.L., and Chen, S.G., Synthesis and photocatalytic activity of nano-cobalt ferrite catalyst for the photo-degradation various dyes under simulated sunlight irradiation, Mater. Sci. Semicond. Process., 2019, vol. 91, pp. 367–376.

Dos Santos, J.M.N., Pereira, C.R., Pinto, L.A.A., Frantz, T., Lima, E.C., Foletto, E.L., and Dotto, G.L., Synthesis of a novel CoFe2O4/chitosan magnetic composite for fast adsorption of indigotine blue dye, Carbohydr. Polym., 2019, vol. 217, pp. 6–14.

Olusegun, S.J., Freitas, E.T.F., Lara, L.R.S., Stumpf, H.O., and Mohallem, N.D., Effect of drying process and calcination on the structural and magnetic properties of cobalt ferrite, Ceram. Int., 2019, vol. 45, no. 7, pp. 8734–8743.

Georgiou, Y., Papadas, I.T., Mouzourakis, E., Skliri, E., Armatas, G.S., and Deligiannakis, Y., Mesoporous spinel CoFe2O4 as an efficient adsorbent for arsenite removal from water: high efficiency via control of the particle assemblage configuration, Environ. Sci.-Nano, 2019, vol. 6, no. 4, pp. 1156–1167.

Ren, F., Zhu, G., Ren, P., Wang, K., Cui, X., and Yan, X., Cyanate ester resin filled with graphene nanosheets and CoFe2O4–reduced graphene oxide nanohybrids as a microwave absorber, Appl. Surf. Sci., 2015, vol. 351, pp. 40–47.

Huang, S., Xu, Yu., Xie, M., Xu, H., He, M., Xia, Ji., Huang, L., and Li, H., Synthesis of magnetic CoFe2O4/g-C3N4 composite and its enhancement of photocatalytic ability under visible-light, Colloids Surf. A, 2015, vol. 478, pp. 71–80.

Lisnevskaya, I.V. and Levshina, N.A., Influence of the preparation conditions and percolation threshold on the properties of lead zirconate titanate/cobalt nickel ferrite magnetoelectric composites, Inorg. Mater., 2018, vol. 54, no. 8, pp. 851–858.https://doi.org/10.1134/S0020168518080113

Ma, Yu., Wang, Q., and Xing, Sh., Insight into the catalytic mechanism of γ-Fe2O3/ZnFe2O4 for hydrogen peroxide activation under visible light, J. Colloid Interface Sci., 2018, vol. 529, pp. 247–254.

Smolii, V.A., Kosarev, A.S., Yatsenko, E.A., and Gol’tsman, B.M., Physicochemical aspects of the preparation of foam glass materials based on glass scrap and plant ash and slag, Izv. Vyssh. Uchebn. Zaved. Severo-Kavkaz. Region. Ser.: Tekh. Nauki, 2018, no. 3 (199), pp. 112–118.

Semchenko, V.V., Shabel’skaya, N.P., and Kuz’mina, Ya.A., Synthesis and catalytic properties of zinc ferrite nanoparticles, Usp. Sovrem. Estestvoznan., 2018, no. 4, pp. 36–41.

Gabriel, C., Raptopoulou, C.P., Drouza, C., Lalioti, N., and Salifoglou, A., Synthesis, spectroscopic, structural and magnetic studies of new binary Cr(III)-citrate pH-specific structural variants from aqueous media, Polyhedron, 2009, vol. 28, pp. 3209–3220.

Funding

This work was supported by the Russian Science Foundation, project no. 18-19-00455: Development of Integrated Protection Technology for Oil and Gas Pipelines Operated under Russian Far East Conditions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Shabel’skaya, N.P., Yatsenko, E.A., Medvedev, R.P. et al. Application of Foam Glass Based on Glass Scrap and Plant Ash and Slag for the Preparation of Catalytically Active Materials. Inorg Mater 56, 765–769 (2020). https://doi.org/10.1134/S0020168520070146

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168520070146