Abstract—

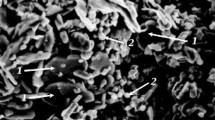

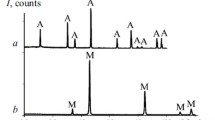

We have studied the sintering of ceramic samples based on magnesium oxide, alumina, and magnesium aluminate spinel in order to assess the conceptual feasibility of producing ceramic foam materials in the Al2O3–MgO system and examined the effect of sintering aids on the sintering process. The range of firing temperatures has been found that ensures the preparation of materials with an open cellular pore structure: the optimal temperatures are from 1600 to 1700°C. The porosity of the synthesized materials is up to 85% and their compressive strength reaches 1.4 MPa.

Similar content being viewed by others

REFERENCES

Kablov, E.N., Innovative projects at the All-Russia Research Institute of Aviation Materials Russian Federation State Scientific Center (Federal State Unitary Enterprise) for implementing “Strategic directions in materials and materials processing technologies development over a period up to 2030,” Aviatsionnye Mater. Tekhnol., 2015, no. 1, pp. 3–33. https://doi.org/10.18577/2071-9140-2015-0-1-3-33

Kablov, E.N., At the intersection of science, education, and industry, Ekspert, 2015 no. 15 (941), pp. 49–53.

Taslicukur, Z., Balaban, C., and Kuskonmaz, N., Production of ceramic foam filters for molten metal filtration using expanded polystyrene, J. Eur. Ceram. Soc., 2007, no. 27, pp. 637–640.

RF Patent 2 377 224, Byull. Izobret., 2009, no. 9.

RF Patent 2 580 959, Byull. Izobret., 2016, no. 10.

US Patent 4 664 858, 1987.

Kablov, E.N., Shchetanov, B.V., Ivakhnenko, Yu.A., and Balinova, Yu.A., Promising high-temperature reinforcing fibers for metallic and ceramic composite materials, Tr. Vseross. Inst. Aviatsionnykh Mater. Elektron. Nauchno-Tekh. Zh., 2013, no. 2, paper 5. http://www.viam-works.ru. Cited March 4, 2019.

Buchilin, N.V., Prager, E.P., and Ivakhnenko, Yu.A., Effect of plasticizing additives on rheological characteristics of slips for the preparation of alumina-based porous ceramic materials, Tr. Vseross. Inst. Aviatsionnykh Mater. Elektron. Nauchno-Tekh. Zh., 2016, no. 8, paper 06. http://www.viam-works.ru. Cited March 7, 2019.https://doi.org/10.18577/2307-6046-2016-0-8-6-6

Senina, M.O., Lemeshev, D.O., Kolesnikov, V.A., Methods of synthesizing alumomagnesium spinel powders for obtaining transparent ceramic (review), Steklo Keram., 2017, no. 10, pp. 19–25.

Gorshkov, V.A., Miloserdov, P.A., Yukhvid, V.I., Sachkova, N.V., and Kovalev, I.D., Preparation of magnesium aluminate spinel by self-propagating high-temperature synthesis metallurgy methods, Inorg. Mater., 2017, vol. 53, no. 10, pp. 1046–1052.

Buchilin, N.V., Lyulyukina, G.Yu., and Varrik, N.M., Effect of firing conditions on the structure and properties of highly porous mullite-based ceramic materials, Tr. Vseross. Inst. Aviatsionnykh Mater. Elektron. Nauchno-Tekh. Zh., 2017, no. 5 (53), paper 04, pp. 32–41. http://www.viam-works.ru. Cited March 7, 2019. https://doi.org/10.18577/2307-6046-2017-0-5-4-4

Kryuchkov, Yu.N., Determination of the average capillary radius in porous materials, Steklo Keram., 2018, no. 4, pp. 16–21.

Slyusar’, O.A. and Uvarov, V.M., Effect of complex additives on ceramic slip mobility, Steklo Keram., 2017, no. 2, pp. 44–46.

Kichkailo, O.V. and Levitskii, I.A., Rheological characteristics of slips in making heat-resistant lithium-aluminum-silicate ceramic, Steklo Keram., 2017, no. 7, pp. 37–44.

Evteev, A.A., Some aspects of optimizing the firing schedule of ceramic composites containing eutectic additives, Tr. Vseross. Inst. Aviatsionnykh Mater. Elektron. Nauchno-Tekh. Zh., 2016, no. 2 (38), pp. 101–106. http://www.viam-works.ru. Cited March 7, 2019. https://doi.org/10.18577/2307-6046-2016-0-2-12-12

Shchegoleva, N.E., Chainikova, A.S., and Orlova, L.A., Sintering process in the preparation of glass-ceramics based on strontium aluminosilicate glass by semidry pressing, Aviatsionnye Mater. Tekhnol., 2018, no. 4 (53), pp. 55–62. https://doi.org/10.18577/2071-9140-2018-0-4-55-62

Safronova, T.V., Putlyaev, V.I., Filippov, Ya.Yu., Shatalova, T.B., and Fatin, D.S., Ceramics based on brushite powder synthesized from calcium nitrate and disodium and dipotassium hydrogen phosphates, Inorg. Mater., 2018, vol. 54, no. 2, pp. 195–207.

Savinykh, D.O., Khainakov, S.A., Boldin, M.S., Orlova, A.I., Aleksandrov, A.A., Lantsev, E.A., Sakharov, N.V., Murashov, A.A., Garcia-Granda, S., Nokhrin, A.V., and Chuvil’deev, V.N., Preparation of NZP-type Ca0.75 + 0.5xZr1.5Fe0.5(PO4)3 –x(SiO4)x powders and ceramic, thermal expansion behavior, Inorg. Mater., 2018, vol. 54, no. 12, pp. 1267–1273.

Khimicheskaya tekhnologiya keramiki: Uch. posobie dlya vuzov (Chemical Technology of Ceramics: A Learning Guide for Higher Education Institutions), Guzman, I.Ya., Ed., Moscow: OOO RIF Stroimaterialy, 2003.

Zhitnyuk, S.V., Oxygen-free ceramic materials for aerospace engineering (a review), Tr. Vseross. Inst. Aviatsionnykh Mater. Elektron. Nauchno-Tekh. Zh., 2018, no. 8 (68), pp. 81–88. http://www.viam-works.ru. Cited March 7, 2019.https://doi.org/10.18577/2307-6046-2018-0-8-81-88

Kashin, D.S., Dergacheva, P.E., and Stekhov, P.A., Refractory coatings produced by slip casting (a review), Tr. Vseross. Inst. Aviatsionnykh Mater. Elektron. Nauchno-Tekh. Zh., 2018, no. 5 (65), pp. 64–75. http://www.viam-works.ru. Cited March 7, 2019. https://doi.org/10.18577/2307-6046-2018-0-5-64-75

Kovtunov, A.I., Khokhlov, Yu.Yu., and Myamin, S.V., Fabrication technology and properties of composite foams, Aviatsionnye Mater. Tekhnol., 2015, no. 3 (36), pp. 64–68. https://doi.org/10.18577/2071-9140-2015-0-3-64-68

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Buchilin, N.V., Basargin, O.V., Varrik, N.M. et al. Sintering Behavior of Highly Porous Ceramic Materials Based on the Al2O3–MgO System. Inorg Mater 56, 417–424 (2020). https://doi.org/10.1134/S0020168520040032

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168520040032