Abstract—

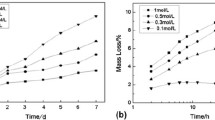

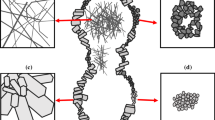

A process has been proposed for the preparation of porous reaction-bonded silicon nitride (RBSN) via the addition of a pore former, uniaxial pressing, and subsequent reaction sintering in a vacuum furnace. As a pore former, we used a commercially available powder consisting of hollow polymer microspheres (Akzonobel) with an average diameter of 9 μm. We have studied the effect of pore former content in green compacts on the mechanical, dielectric, and thermophysical properties of the ceramics. The proposed process allows one to prepare porous RBSN with the following properties: σb = 48 MPa, ε = 3.2, tan δ = 35 × 10–4 at a frequency of 10 GHz, and λ = 0.96 W/(m K) at 1100°C. The ceramic obtained in this study is potentially attractive for industrial application as a radar-transparent structural material with reduced thermal conductivity.

Similar content being viewed by others

REFERENCES

Andrievskii, R.A. and Spivak, I.I., Nitrid kremniya i materialy na ego osnove (Silicon Nitride and Related Materials), Moscow: Metallurgiya, 1984.

Ziegler, G., Heinrich, J., and Wotting, G., Relationships between processing, microstructure and properties of dense and reaction-bonded silicon nitride, J. Mater. Sci., 1987, vol. 22, pp. 3041–3086.

Nair, R.U., Vandana, S., Sandhya, S., and Jha, R.M., Temperature-dependent electromagnetic performance predictions of a hypersonic streamlined radome, Prog. Electromagn. Res., 2015, vol. 154, pp. 65–78.

Romashin, A.G., Gaidachuk, V.E., Karpov, Ya.S., and Rusin, M.Yu., Radioprozrachnye obtekateli letatel’nykh apparatov. Proektirovanie, konstruktsionnye materialy, tekhnologiya proizvodstva, ispytaniya. Uchebnoe posobie (Streamlined Radomes for Aircraft: Design Engineering, Structural Materials, Technological Aspects of Production, and Testing. A Learning Guide), Kharkiv: Nats. Aerokosm. Univ. “Kharkiv. Aviatsionnyi Institut,” 2003, p. 239.

Zhou, Y., Hyuga, H., Kusano, D., Yoshizawa, Y., Ohji, T., and Hirao, K., Development of high-thermal-conductivity silicon nitride ceramics, J. Asian Ceram. Soc., 2015, vol. 3, pp. 221–229. https://doi.org/10.1016/j.jascer.2015.03.003

Kitayama, M., Hirao, K., Toriyama, M., and Kanzaki, S., Thermal conductivity of β-Si3N4: effect of various microstructural factors, J. Am. Ceram. Soc., 1999, vol. 82, no. 11, pp. 3105–3112.

Kaidash, O.N., Fesenko, I.P., and Kryl’, Ya.A., Heat conductivity, physicomechanical properties and interrelations of them and structures of pressureless sintered composites produced of Si3N4–Al2O3–Y2O3(–ZrO2) nanodispersed system, J. Superhard Mater., 2014, vol. 36, no. 2, pp. 96–104.

Watari, K., Hirao, K., and Toriyama, M., Effect of grain size on the thermal conductivity of Si3N4, J. Am. Ceram. Soc., 1999, vol. 82, no. 3, pp. 777–779.

Hirosaki, N., Ogata, S., Kocer, C., et al., Molecular dynamics calculation of the ideal thermal conductivity of single-crystal α- and β-Si3N4, Phys. Rev. B: Condens. Matter Mater. Phys., 2002, vol. 65, no. 134 110. https://doi.org/10.1103/PhysRevB.65.134110

Antsiferov, V.N. and Gilev, V.G., Properties of porous silicon-nitride materials, Ogneupory, 1988, no. 7, pp. 20–23.

Kornienko, P.A., Naumenko, V.Ya., Chekhovich, V.A., et al., Strength and thermophysical properties of porous silicon nitride materials, Sov. Powder Metall. Met. Ceram., 1984, vol. 23, no. 11, pp. 875–877.

Li, J.-Q., Fa, L., Zhu, D.-M., and Zhou, W.-C., Preparation and dielectric properties of porous silicon nitride ceramics, Trans. Nonferrous Met. Soc. China, 2006, vol. 16, pp. 487–489.

Jiang, G.-P., Yang, J.-F., and Gao, J.-Q., Porous silicon nitride ceramics prepared by extrusion using starch as binder, J. Am. Ceram. Soc., 2008, vol. 91, no. 11, pp. 3510–3516. https://doi.org/10.1111/j.1551-2916.2008.02701.x

Fukasawa, T., Deng, Z.-Y., and Ando, M., Synthesis of porous silicon nitride with unidirectionally aligned channels using freeze-drying process, J. Am. Ceram. Soc., 2002, vol. 85, no. 9, pp. 2151–2155. https://doi.org/10.1111/j.1151-2916.2002.tb00426.x

Gonzenbach, U.T., Studart, A.R., Tervoort, E., and Gauckler, L.J., Macroporous ceramics from particle-stabilized wet foams, J. Am. Ceram. Soc., 2007, vol. 90, no. 1, pp. 16–22. https://doi.org/10.1111/j.1551-2916.2006.01328.x

Li, X., Wub, P., and Zhu, D., Effect of foaming pressure on the properties of porous Si3N4 ceramic fabricated by a technique combining foaming and pressureless sintering, Scr. Mater., 2013, vol. 68, no. 11, pp. 877–880. https://doi.org/10.1016/j.scriptamat.2013.02.033

Yu, J., Yang, J., Li, H., Xi, X., and Huang, Y., Study on particle-stabilized Si3N4 ceramic foams, Mater. Lett., 2011, vol. 65, no. 12, pp. 1801–1804. https://doi.org/10.1016/j.matlet.2011.03.082

Kandi, K.K. Thallapalli, N., et al., Development of silicon nitride-based ceramic radomes, Int. J. Appl. Ceram. Technol., 2015, vol. 12, no. 5, pp. 909–920. https://doi.org/10.1111/ijac.12305

Li, B., Jiang, P., Yan, M.-W., Li, Y., Hou, X.-M., and Chen, J.-H., Characterization and properties of rapid fabrication of network porous Si3N4 ceramics, J. Alloys Compd., 2017, vol. 709, pp. 717–723. https://doi.org/10.1016/j.jallcom.2017.03.223

Walton, J.D., Proc. 2nd Int. Conf. on Electromagnetic Windows, Paris, 1971, vol. 2, pp. 8–10.

Sillapasa, K., Danchaivijit, S., and Sujirote, K., Effects of silicon powder size on the processing of reaction-bonded silicon nitride, J. Met.,Mater. Miner., 2005, vol. 15, no. 2, pp. 97–102.

Kawai, C. and Yamakawa, A., Effect of porosity and microstructure on the strength of Si3N4: designed microstructure for high strength, high thermal shock resistance, and facile machining, J. Am. Ceram. Soc., 1997, vol. 80, no. 10, pp. 2705–2708.

Danforth, S.C., Jennings, H.M., and Richman, M.H., The influence of microstructure on the strength of reaction bonded silicon nitride (RBSN), Acta Metall., 1979, vol. 27, no. 1, pp. 123–130.

Zhou, J., Fan, J.-P., Sun, G.-L., Zhang, J.-Y., et al., Preparation and properties of porous silicon nitride ceramics with uniform spherical pores by improved pore-forming agent method, J. Alloys Compd., 2015, vol. 632, pp. 655–660. https://doi.org/10.1016/j.jallcom.2015.01.305

Park, D.-S., Lee, M.-W., Kim, H.-D., Park, Y.-J., and Jung, Y.-G., Fabrication and properties of porous RBSN, Key Eng. Mater., 2005, vol. 287, pp. 277–281. https://doi.org/10.4028/www.scientific.net/KEM.287.277

Moulson, A.J., Reaction-bonded silicon nitride: its formation and properties, J. Mater. Sci., 1979, vol. 14, no. 5, pp. 1017–1051. https://doi.org/10.1007/BF00561287

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Georgiu, N.K., Georgiu, I.F., Klemazov, K.V. et al. Porous Reaction-Bonded Silicon Nitride Ceramics: Fabrication Using Hollow Polymer Microspheres and Properties. Inorg Mater 55, 1290–1296 (2019). https://doi.org/10.1134/S0020168519120057

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168519120057