Abstract—

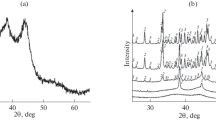

Using a variety of characterization techniques (differential scanning calorimetry, X-ray diffraction, high-resolution transmission electron microscopy, resistivity measurements, nanoindentation, and uniaxial tension testing), we have studied structural changes produced in the amorphous phase of the Fe77B7Nb2.1Si13Cu0.9 alloy by heating in vacuum to 750°C and lamp processing (LP) with the use of pulsed xenon lamps to a fluence F = 120 J/cm2 on the sample surface. Increasing the temperature or fluence leads to three stages of structural transformations: structural relaxation of the amorphous phase below 450°C and two stages of crystallization, which show up as nonmonotonic behavior of the hardness and local plasticity of the samples. With a common character of the structural changes, the effect of LP shows up as an increase in crystallization rate (the processing time is 200 times shorter). In both cases, the fraction of plastic strain in indentation work in amorphous and crystallized samples is 25% larger than that in amorphous–crystalline composites. It has been shown that irreversible deformation of amorphous samples by uniaxial tension leads to structural relaxation and an increase in the size of the relaxation zone.

Similar content being viewed by others

Notes

We are grateful to G.V. Afonin (Voronezh State Pedagogical University) for his assistance with this study.

REFERENCES

Greer, A.L., Metallic glasses, Physical Metallurgy, Laughlin, D.E. and Hono, K, Eds., Amlsterdam: Elsevier, 2015, 5th ed., pp. 305–385.

Skryshevskii, A.F., Strukturnyi analiz zhidkostei i amorfnykh tel (Structural Analysis of Liquids and Amorphous Materials), Moscow: Vysshaya Shkola, 1980.

Bataronov, I.L., Bondarev, A.V., Urazov, D.V., and Barmin, Yu.V., Analysis of the atomic structure of amorphous alloys in terms of percolation theory, Izv. Akad. Nauk, Ser. Fiz., 2005, vol. 69, no. 8, pp. 1162–1167.

Suzuki K., Fuzimori, H., and Hashimoto, K., Amorfnye metally (Amorphous Metals), Moscow: Metallurgiya, 1987.

Schuh, C.A., Hufnagel, T.C., and Ramamurty, U., Mechanical behavior of amorphous alloys, Acta Mater., 2007, vol. 55, no. 12, pp. 4067–4109.

Glezer, A.M., Potekaev, A.I., and Cheretaeva, A.O., Temperaturno-vremennaya stabil’nost' amorfnykh splavov (Thermal and Temporal Stability of Amorphous Alloys), Tomsk: NTL, 2015.

Glezer, A.M. and Shurygina, N.A., Amorfno-nanokristallicheskie splavy (Amorphous–Nanocrystalline Alloys), Moscow: Fizmatlit, 2013.

Kissinger, H.E., Reaction kinetics in differential thermal analysis, Anal. Chem., 1957, vol. 29, pp. 1702–1706.

Huang, S., Structure and Structure Analysis of Amorphous Materials, Oxford: Clarendon, 1984, p. 48.

Abrosimova, G.E., Aronin, A.S., and Kholstin, N.N., On the determination of the volume fraction of the crystalline phase in amorphous–crystalline alloys, Phys. Solid State, 2010, vol. 52, no. 3, pp. 445–451.

Le Bail, A., Duroy, H., and Fourquet, J.L., Ab initio structure determination of LiSbWO6 by X-ray powder diffraction, Mater. Res. Bull., 1988, vol. 23, no. 3, pp. 447–452.

Petricek, V., Dusek, M., and Palatinus, L., Crystallographic computing system JANA 2006: general features, Z. Kristallogr., 2014, vol. 229, no. 5, pp. 345–352.

Wojdir, M., Fityk: a general-purpose peak fitting program, J. Appl. Crystallogr., 2010, vol. 43, pp. 1126–1128.

Oliver, W.C., An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments, J. Mater. Res., 1992, vol. 7, no. 6, pp. 1564–1583.

Antonova, M.S., Belonogov, E.K., Boryak, A.V., Vavilova, V.V., Ievlev, V.M., Kannykin, S.V., and Palii, N.A., Photoactivated nanocrystallization and hardness of Fe78P20Si2 alloy, Inorg. Mater., 2015, vol. 51, no. 3, pp. 283–287.

Diagrammy sostoyaniya dvoinykh metallicheskikh sistem. Spravochnik (Phase Diagrams of Binary Metallic Systems: A Handbook), Lyakishev, N.P., Ed., Moscow: Mashinostroenie, 1997, vol. 2.

Tomida, T., Crystallization of Fe–Si–B–Ga–Nb alloy, Mater. Sci. Eng., 1994, vol. 180, pp. 521–525.

Serebryakov, A.V., Role of niobium in the formation of nanocrystals in amorphous Fe73.5Si13.5B9Nb3Cu1 alloy, Kompoz. Nanostrukt., 2009, no. 4, pp. 42–46.

Schuh, C.A., Lund, A.C., and Nieh, T.G., New regime of homogeneous flow in the deformation map of metallic glasses, Acta Mater., 2004, vol. 52, pp. 5879–5891.

Golovin, Yu.I., Nanoindentirovanie i ego vozmozhnosti (Nanoindentation and Its Potentialities), Moscow: Mashinostroenie, 2009.

FUNDING

This work was supported by the Russian Foundation for Basic Research, grant no. 17-03-01140-a.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Ievlev, V.M., Kannykin, S.V., Il’inova, T.N. et al. Heat Treatment- and Lamp Processing-Induced Structural Transformations of an Amorphous Fe77B7Nb2.1Si13Cu0.9 Alloy and Nonmonotonic Behavior of Its Mechanical Properties. Inorg Mater 55, 659–668 (2019). https://doi.org/10.1134/S0020168519070070

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168519070070