Abstract—

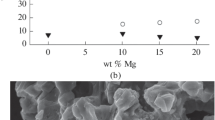

Technologically viable principles have been developed for the preparation of titanium and zirconium powders via reduction of metal oxides. We have studied the effect of synthesis conditions (starting-mixture composition and relationships between reactants) on the composition, structure, and particle size of the powders. The results demonstrate that the addition of excess magnesium to the starting mixture leads to the complete reduction of the oxides and that reducing the combustion temperature of the starting mixture leads to an increase in the percentage of zirconium oxide in the final product. The titanium and zirconium powders prepared in the combustion regime with a reduction stage consist of agglomerates of particles ranging widely in size: from large (several microns) to ultrafine and nanoscale particles. The use of magnesium perchlorate as a heating additive leads to the formation of a titanium–zirconium solid solution. The composition of the powders has been determined by chemical analysis, microstructural analysis, and X-ray diffraction.

Similar content being viewed by others

REFERENCES

Niinomi, M. and Nakai, M., Titanium-based biomaterials for preventing stress shielding between implant devices and bone, Int. J. Biomater., 2011, vol. 2011, paper 836 587. https://doi.org/10.1155/2011/836587

Rack, H.J. and Qazi, J.I., Titanium alloys for biomedical applications, Mater. Sci. Eng., 2006, vol. 26, pp. 1269–1277.

Karaja, A., Sermond, B., and Ilfing, H., RF Patent 2 507 034.

Hsu, H.-C., Wu, S.-C., Sung, Y.-C., and Ho, W.-F., The structure and mechanical properties of as-cast Zr–Ti alloys, J. Alloys Compd., 2009, vol. 488, pp. 279–283.

Ho, W.-F., Chen, W.-K., Wu, S.-C., and Hsu, H.-C., Structure, mechanical properties, and grindability of dental Ti–Zr alloys, J. Mater. Sci. Mater. Med., 2008, vol. 19, pp. 3179–3186.

Correa, D.R.N., Vicente, F.B., Donato, T.A.G., Arana-Chavez, V.E., Buzalaf, M.A.R., and Grandini, C.R., The effect of the solute on the structure, selected mechanical properties, and biocompatibility of Ti–Zr system alloys for dental applications, Mater. Sci. Eng., 2014, vol. 34, pp. 354–359.

Won-Gi Kim and Han-Cheol Choe, Nanostructure and corrosion behaviors of nanotube formed Ti–Zr alloy, Trans. Nonferrous Met. Soc. China, 2009, vol. 19, pp. 1005–1008.

Luz, T., Henriques, V., de Oliveira, J., and Diniz, E., Production of Ti–Zr alloy by powder metallurgy, SAE Technical Paper 2013-36-0388, 2013. https://doi.org/10.4271/2013-36-0388

Lee, D.-W., Baek, Y.-K., Lee, W.-J., and Wang, J.-P., Study on synthesis of Zr–Ti alloy powder using molten magnesium, J. Mater. Res. Innovations, 2013, vol. 17, no. 2, pp. 113–117.

Shulin Wang, Shengjuan Li, Bo Xua, Fangfei Cai, Laiqiang Li, and Junxiang Lei, Synthesis of binary nano-composite of Ti50Zr50 and its characterization, J. Alloys Compd., 2007, vol. 429, pp. 227–232.

Kuroda, D., Niinomib, M., Morinaga, M., Katod, Y., and Yashirod, T., Design and mechanical properties of new β type titanium alloys for implant materials, Mater. Sci. Eng., A, 1998, vol. 243, pp. 244–249. doi.org/ https://doi.org/10.1016/S0921-5093(97)00808-3

Farrar, P.A. and Adler, S., On the system titanium–zirconium, Trans. Metall. Soc. AIME, 1966, vol. 236, pp. 1061–1064.

ACKNOWLEDGMENTS

This work was supported by the Russian Foundation for Basic Research, project no. 16-29-01035ofi m.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by O. Tsarev

Rights and permissions

About this article

Cite this article

Vershinnikov, V.I., Kovalev, D.Y., Ignat’eva, T.I. et al. Feasibility of Producing a Ti–Zr Alloy via Combustion in the TiO2–ZrO2–Mg System. Inorg Mater 55, 185–190 (2019). https://doi.org/10.1134/S0020168519020146

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168519020146