Abstract

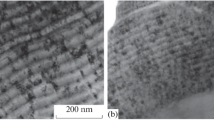

We have studied structure and phase formation processes in the Ti-N-Ni system during the growth of coatings by cathodic arc physical vapor deposition (PVD). The incorporation of nickel has been shown to reduce the crystallite size of TiN from 100–120 to 15–18 nm. This is accompanied by a transition from a columnar microstructure, typical of PVD TiN coatings, to an equiaxed one. In the concentration range 0 to 12–13 at %, the nickel in the coatings is X-ray amorphous. Further increasing the nickel content leads to the formation of the intermetallic phase TiNi, which is in turn accompanied by the generation of pores in the structure of the coating. We have determined optimal nickel concentrations in the composite coatings (8–12 at %) that ensure hardness, Young’s modulus, H 3/E 2, and H/E of 52 GPa, 516 GPa, 0.57 GPa, and 0.104, respectively. We have demonstrated that the nanostructured TiN-Ni (2.8 to 12 at % Ni) coatings undergo failure by a cohesion mechanism. Complete wear of the coatings only occurred starting at a load of 90 N, attesting to high adhesion/cohesion strength of the system.

Similar content being viewed by others

References

Belous, V.A., Vasil’ev, V.V., Luchaninov, A.A., et al., Hard Ti-Al-N coatings grown from a filtered vacuum arc plasma, Fiz. Inzh. Poverkhn., 2009, vol. 7, no. 3, pp. 216–222.

Pelletier, J. and Anders, A., Plasma based ion implantation and deposition: a review of physics, technology and application, TEEE Trans. Plasma Sci., 2005, vol. 33, no. 6, pp. 1944–1959.

Singh, K., Lymaye, P.K., Soni, N.L., Grover, A.K., Agrawal, R.G., and Suri, A.K., Wear studies of (Ti-Al)N coatings deposited by reactive magnetron sputtering, Wear, 2005, vol. 258, nos. 11–12, pp. 1813–1824.

Harris, S.G., Doyle, E.D., and Vlasveld, A.C., A study of the wear mechanisms of Ti1 − x AlxN and Ti1 − x − y AlxCryN coated high-speed steel twist drills under dry machining conditions, Wear, 2003, vol. 254, pp. 723–734.

Veprek, S. and Veprek-Heijman, M.J.G., Industrial applications of superhard nanocomposite coatings, Surf. Coat. Technol., 2008, vol. 202, pp. 5063–5073.

Li, Z.G., Miyake, S., Kumagai, M., et al., Hard nanocomposite Ti-Cu-N films prepared by d. c. reactive magnetron co-sputtering, Surf. Coat. Technol., 2004, vol. 183, pp. 62–68.

Elyutin, A.V., Blinkov, I.V., Volkhonsky, A.O., and Belov, D.S., Properties of nanocrystalline arc PVD TiN-Cu coatings, Inorg. Mater., 2013, vol. 49, no. 11, pp. 1106–1112.

Akbari, A., Riviere, J.P., Templier, C., and Bourhis, E.L., Structural and mechanical properties of IBAD deposited nanocomposite Ti-Ni-N coatings, Surf. Coat. Technol., 2006, vol. 200, pp. 6298–6302.

Akbari, A., Templier, C., and Beaufort, M., Ion beam assisted deposition of TiN-Ni nanocomposite coatings, Surf. Coat. Technol., 2011, vol. 206, pp. 972–975.

Kumar, M., Mishra, S., and Mitra, R., Effect of Ar: N2 ratio on structure and properties of Ni-TiN nanocomposite thin films processed by reactive rf/dc magnetron sputtering, Surf. Coat. Technol., 2013, vol. 228, pp. 100–114.

Andrievskii, R.A., Nanomaterials: concept and current issues, Ross. Khim. Zh., 2002, vol. 19, no. 5, pp. 50–56.

Gutkin, M.Yu. and Ovid’ko, I.A., Fizicheskaya mekhanika deformiruemykh nanostruktur (Physical Mechanics of Deformed Nanostructures), vol. 1: Nanokristallicheskie Materialy (Nanocrystalline Materials), St. Petersburg: Yanus, 2003, p. 194.

Shelekhov, E.V. and Sviridova, T.A., Programs for X-ray analysis of polycrystals, Metalloved. Term. Obrab. Met., 2000, no. 8, pp. 16–19.

Ivanov, A.N., Shelekhov, E.V., and Kuz’mina, E.N., Voigt fitting procedure for assessing parameters of nanostructures from X-ray diffraction line profiles, Zavod. Lab., Diagn. Mater., 2004, vol. 70, no. 11, pp. 29–33.

Golovin, Yu.I., Vvedenie v nanotekhniku (Introduction to Nanoengineering), Moscow: Mashinostroenie, 2007, p. 496.

ISO/FDIS 14577-1:2002 Standard: Metallic Materials-Instrumental Indentation Test for Hardness and Materials Parameters, Geneva: ISO Central Secretariat, 2002.

Kislyi, P.S., Bodnaruk, N.I., Borovikova, M.S., et al., Kermety (Cermets), Kiev: Naukova Dumka, 1985, p. 272.

Leyland, A. and Matthews, A., On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behavior, Wear, 2000, vol. 246, no. 1, pp. 1–11.

Tsui, T.Y., Phar, G.H., Oliver, W.C., White, W.C., et al., Nanoindentation and nanoscratching of hard carbon coatings for magnetic disks, Mater. Res. Soc. Symp. Proc., 1995, vol. 383, pp. 447–452.

Yaomin Zhou, Reo Asaki, We-Hyo Soe, Ryoichi Yamamoto, Rong Chen, and Akira Iwabuchi, Hardness anomaly, plastic deformation work and fretting wear properties of polycrystalline TiN/CrN multilayers, Wear, 1999, vol. 236, pp. 159–164.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © I.V. Blinkov, A.O. Volkhonsky, D.S. Belov, V.I. Blinkov, E.A. Skryleva, N.V. Shvyndina, 2015, published in Neorganicheskie Materialy, 2015, Vol. 51, No. 2, pp. 163–170.

Rights and permissions

About this article

Cite this article

Blinkov, I.V., Volkhonsky, A.O., Belov, D.S. et al. Nanostructuring and property modification of arc PVD TiN coatings by nickel. Inorg Mater 51, 122–128 (2015). https://doi.org/10.1134/S002016851502003X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S002016851502003X