Abstract

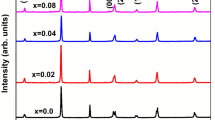

Barium titanate powders differing in particle size (110–740 nm) were prepared by calcining barium titanyl oxalate precipitated by the Merker method. The powders were sintered to produce PTCR ceramics with the composition 100(Ba0.89Ca0.08Pb0.03)TiO3 + 0.8TiO2 + 0.7Y + 0.1Mn + 2.5SiO2 and electrical properties of the ceramics were studied. The results demonstrate that improving the crystallinity of the barium titanate powder suppresses recrystallization of the ceramics and has a significant effect on their resistance ratio and electric strength. We found the optimal range of calcination temperatures (950–1000°C) for barium titanyl oxalate which ensures the highest electric strength of thermistors with a resistance of 31 Ω. The average crystallite size of the parent barium titanate powder is ∼250–320 nm.

Similar content being viewed by others

References

Chen, Y.L. and Yang, S.F., PTCR Effect in Donor Doped Barium Titanate: Review of Compositions, Microstructures, Processing and Properties, Adv. Appl. Ceram., 2011, vol. 110, no. 5, pp. 257–269.

Al-Allak, H.M., Anomalous Increase in the Resistivity of n-Doped BaTiO3-Based Ceramics with Pressure Observed at Room Temperature, J. Am. Ceram. Soc., 2011, vol. 94, no. 9, pp. 2757–2760.

Syrtsov, S.R., Shut, V.N., Kashevich, I.F., et al., Positive Temperature Coefficient of Resistivity in Thin Films of Barium Titanate, Mater. Sci. Semicond. Process., 2002, vol. 5, nos. 2–3, pp. 223–225.

Blamey, J.M. and Parry, T.V., The Effect of Processing Variables on the Mechanical and Electrical Properties of Barium-Titanate Positive-Temperature-Coefficient-Of-Resistance Ceramics: I. Additives and Processing Prior to Sintering, J. Mater. Sci., 1993, vol. 28, no. 16, pp. 4311–4316.

Park, K., Ha, J.-G., Kim, C.-W., and Kim, J.-G., PTCR Characteristics of Semiconducting Barium Titanate Ceramics Produced by High-Energy Ball-Milling, J. Mater. Sci., 2008, vol. 19, no. 4, pp. 357–362.

Pithan, C., Hennings, D., and Waser, R., Progress in the Synthesis of Nanocrystalline BaTiO3 Powders for MLCC, Int. J. Appl. Ceram. Technol., 2005, vol. 2, no. 1, pp. 1–14.

Clabaugh, W.S., Swiggard, E.M., and Gilchrist, R., Preparation of Barium Titanyl Oxalate Tetrahydrate for Conversion to Barium Titanate of High Purity, J. Res. Natl. Bur. Stand., 1956, vol. 56, no. 5, pp. 289–291.

Vakhmenina, O.N., Bokman, G.Yu., Kharash, M.Sh., et al., RF Patent 2 224 718, 2004.

Shut, V.N. and Kostomarov, S.V., Properties of Barium Titanate Powders in Relation to the Heat Treatment of the Barium Titanyl Oxalate Precursor, Inorg. Mater., 2012, vol. 48, no. 6, pp. 613–618.

Shut, V., Kostomarov, S., and Gavrilov, A., PTCR Barium Titanate Ceramics Obtained from Oxalate-Derived Powders with Varying Crystallinity, J. Mater. Sci., 2008, vol. 43, no. 15, pp. 5251–5257.

Shut, V.N., Kostomarov, S.V., and Gavrilov, A.V., PTCR Ceramics Produced from Oxalate-Derived Barium Titanate, Inorg. Mater., 2008, vol. 44, no. 8, pp. 905–910.

Shut, V.N. and Kostomarov, S.V., Semiconducting Ceramics Produced Using Nanocrystalline Barium Titanate Powder, Inorg. Mater., 2009, vol. 45, no. 12, pp. 1417–1422.

Huybrechts, B., Ishizaki, K., and Takata, M., The Positive Temperature Coefficient of Resistivity in Barium Titanate, J. Mater. Sci., 1995, vol. 30, no. 10, pp. 2463–2474.

Peng, C.J. and Lu, H.Y., Compensation Effect in Semiconducting Barium Titanate, J. Am. Ceram. Soc., 1988, vol. 71, no. 1, pp. 44–46.

Urek, S. and Drofenik, M., PTCR Behavior of Highly Donor Doped BaTiO3, J. Eur. Ceram. Soc., 1999, vol. 19, nos. 6–7, pp. 913–916.

Buscaglia, M.T., Viviani, M., Buscaglia, V., et al., Incorporation of Er3+ into BaTiO3, J. Am. Ceram. Soc., 2002, vol. 85, no. 6, pp. 1569–1575.

Wang, S.F. and Dayton, G.O., Dielectric Properties of Fine-Grained Barium Titanate Based X7R Materials, J. Am. Ceram. Soc., 1999, vol. 82, no. 10, pp. 2677–2682.

Yoon, S.H., Lee, J.-H., Kim, D.-Y., and Hwang, N.M., Effect of the Liquid-Phase Characteristic on the Microstructures and Dielectric Properties of Donor-(Niobium) and Acceptor-(Magnesium) Doped Barium Titanate, J. Am. Ceram. Soc., 2003, vol. 86, no. 1, pp. 88–92.

Brzozowski, E. and Castro, M.S., Influence of Nb5+ and Sb3+ Dopants on the Defect Profile, PTCR Effect and GBBL Characteristics of BaTiO3 Ceramics, J. Eur. Ceram. Soc., 2004, vol. 24, no. 8, pp. 2499–2507.

Mitic, V.V., Nikolic, Z.S., Pavlovic, V.B., et al., Influence of Rare-Earth Dopants on Barium Titanate Ceramics Microstructure and Corresponding Electrical Properties, J. Am. Ceram. Soc., 2010, vol. 93, no. 1, pp. 132–137.

Desu, S.B. and Payne, D.A., Interfacial Segregation in Perovskites. II. Experimental Evidence, J. Am. Ceram. Soc., 1990, vol. 73, no. 11, pp. 3398–3406.

Boltaks, B.I., Diffuziya i tochechnye defekty v poluprovodnikakh (Diffusion and Point Defects in Semiconductors), Leningrad: Nauka, 1972.

Liu, G., Wang, X., Lin, Y., et al., Growth Kinetics of Core-Shell-Structured Grains and Dielectric Constant in Rare-Earth-Doped BaTiO3 Ceramics, J. Appl. Phys., 2005, vol. 98, no. 4, pp. 044 105–044 111.

Glinchuk, M.D., Bykov, I.P., Kornienko, S.M., et al., Influence of Impurities on the Properties of Rare-Earth-Doped Barium-Titanate Ceramics, J. Mater. Chem., 2000, vol. 10, no. 4, pp. 941–947.

Hari, N.S., Padmini, P., and Kutty, T.R.N., Complex Impedance Analyses of n-BaTiO3 Ceramics Showing Positive Temperature Coefficient of Resistance, J. Mater. Sci.: Mater. Electron., 1997, vol. 8, no. 1, pp. 15–22.

Morrison, F.D., Sinclair, D.C., and West, A.R., Characterization of Lanthanum-Doped Barium Titanate Ceramics Using Impedance Spectroscopy, J. Am. Ceram. Soc., 2001, vol. 84, no. 3, pp. 531–538.

Kirstein, K., Reichmann, K., Preis, W., and Mitsche, S., Effect of Commercial Anatase-TiO2 Raw Materials on the Electrical Characteristics of Ceramics with Positive Temperature Coefficient of Resistivity, J. Eur. Ceram. Soc., 2011, vol. 31, no. 13, pp. 2339–2349.

Koschek, G. and Kubalek, E., Grain-Boundary Characteristics and Their Influence on the Electrical Resistance of Barium Titanate Ceramics, J. Am. Ceram. Soc., 1985, vol. 68, no. 11, pp. 582–586.

Pavlov, A.N. and Raevskii, I.P., Varistor Effect in Semiconducting Ferroelectric Ceramics, Zh. Tekh. Fiz., 1997, vol. 67, no. 12, pp. 21–25.

Shut, V.N. and Gavrilov, A.V., Thermal Stresses in Layered Barium Titanate-Based Semiconductor Ceramics, Tech. Phys., 2008, vol. 53, no. 11, pp. 1508–1512.

Roseman, R.D. and Mukherjee, N., PTCR Effect in BaTiO3: Structural Aspects and Grain Boundary Potentials, J. Electroceram., 2003, vol. 10, no. 2, pp. 117–135.

Miki, T., Fujimoto, A., and Jida, S., An Evidence of Trap Activation for Positive Temperature Coefficient of Resistivity in BaTiO3 Ceramics with Substitutional Nb and Mn As Impurities, J. Appl. Phys., 1998, vol. 83, no. 3, pp. 1592–1603.

Chiang, Y.-M. and Takagi, T., Grain-Boundary Chemistry of Barium Titanate and Strontium Titanate: I. High-Temperature Equilibrium Space Charge, J. Am. Ceram. Soc., 1990, vol. 73, no. 11, pp. 3278–3285.

Yoon, S.H., Lee, K.H., and Kim, H., Effect of Acceptors on the Segregation of Donors in Niobium-Doped Barium Titanate Positive Temperature Coefficient Resistors, J. Am. Ceram. Soc., 2000, vol. 83, no. 10, pp. 2463–2472.

V’yunov, O.I., Kovalenco, L.L., and Belous, A.G., The Effect of Isovalent Substitutions and Dopants of 3d-Metals on the Properties of Ferroelectrics-Semiconductors, Condens. Matter Phys., 2003, vol. 6, no. 2, pp. 213–220.

Gallego, M.M. and West, A.R., Effect of Annealing Treatments on Positive Temperature Coefficient of Resistance Properties of Barium Titanate Ceramics and a New Model for the Positive Temperature Coefficient of Resistance Effect, J. Appl. Phys., 2001, vol. 90, no. 1, pp. 394–403.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.N. Shut, S.V. Kostomarov, V.L. Trublovsky, 2012, published in Neorganicheskie Materialy, 2012, Vol. 48, No. 6, pp. 746–752.

Rights and permissions

About this article

Cite this article

Shut, V.N., Kostomarov, S.V. & Trublovsky, V.L. Effect of the crystallinity of BaTiO3 powders prepared using the merker method on the properties of PTCR ceramics. Inorg Mater 48, 648–654 (2012). https://doi.org/10.1134/S0020168512060179

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0020168512060179