Abstract

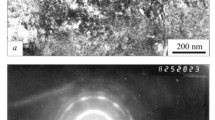

Al-Ni-Cr foils prepared by rapid quenching from the liquid state are studied. The surface of the foils is found to have a cellular morphology, with a microcrystalline, large-block structure and (111) texture. The effect of annealing on the microhardness of the foils is analyzed. The aging behavior of the microhardness is shown to depend on the Ni/Cr ratio.

Similar content being viewed by others

References

Dobatkin, V.I. and Elagin, V.I., Granuliruemye alyuminievye splavy (Granular Aluminum Alloys), Moscow: Metallurgiya, 1981.

Vasil’ev, V.A., Mitin, B.S., and Pashkov, I.N., et al., Vysokoskorostnoe zatverdevanie rasplava (teoriya, tekhnologiya i materialy) (Rapid Melt Solidification: Theory, Technology, and Materials), Mitin, B.S., Ed., Moscow: INTERMET INZhINIRING, 1998.

Mondol’fo, L.F., Struktura i svoistva alyuminievykh splavov (Structure and Properties of Aluminum Alloys), Moscow: Metallurgiya, 1979.

Neumerzhitskaya, E.Yu., Gusakova, S.V., and Shepelevich, V.G., Structure and Properties of Rapidly Solidified Aluminum-Chromium and Aluminum-Nickel Foils, Mashinostroenie, 2004, no. 20, pp. 345–350.

Vasilevich, E.Yu. and Shepelevich, V.G., Structure and Properties of Rapidly Solidified Aluminum-Nickel Foils, Mashinostroenie, 2001, no. 17, p. 256.

Sivtsova, P.A. and Shepelevich, V.G., Structure and Mechanical Properties of Aluminum-Rich Al-Ni-Cr Alloys, Mashinostroenië, 2003, no. 19, pp. 717–720.

Sivtsova, P.A., Structure and Properties of Rapidly Solidified Al-Ni-Cr Foils, Sb. Tr. Molodykh Uch. Nats. Akad. Nauk Resp. Belarus, 2004, vol. 4, pp. 59–63.

García-Escorial, A., Sánchez, B., Cristina, M.C., et al., Rapidly Solidified Al-3Cr-X (Ni, Mo) Ribbons: Structure and Decomposition Behaviour, Mater. Sci. Eng., A, 1991, vol. 134, p. 1204.

Miroshnichenko, I.S., Zakalka iz zhidkogo sostoyaniya (Quenching from the Liquid State), Moscow: Metallurgiya, 1982.

Wassermann, G. and Grewen, J., Texturen metallischer Werkstoffe, Berlin: Springer, 1962, 2nd ed. Translated under the title Tekstury metallicheskikh materialov, Moscow: Metallurgiya, 1969.

Gorelik, S.S., Rastorguev, L.N., and Skakov, Yu.A., Rentgenovskii i electronograficheskii analiz metallov (X-ray and Electron Diffraction Analysis of Metals), Moscow: Metallurgizdat, 1963.

Kalinichenko, A.S. and Bergmann, G.V., Upravlyaemoe napravlennoe zatverdevanie i lazernaya obrabotka: teoriya i praktika (Controlled Directional Solidification and Laser Processing: Theory and Practice), Minsk: Tekhnoprint, 2001.

Li, D.Y. and Szpunar, I.A., A Possible Role for Surface Packing Density in the Formation of {111} Texture in Solidified FCC Metals, Mater. Sci. Lett., 1994, vol. 13, no. 21, pp. 1521–1523.

Sivtsova, P.A. and Shepelevich, V.G., Structure and Mechanical Properties of Al-Ni-Cr Alloys Produced by Rapid Quenching from the Liquid State, Vestn. Beloruss. Gos. Univ., Ser. 1, 2005, no. 1, pp. 47–51.

Author information

Authors and Affiliations

Additional information

Original Russian Text © P.A. Sivtsova, V.G. Shepelevich, 2006, published in Neorganicheskie Materialy, 2006, Vol. 42, No. 3, pp. 307–311.

Rights and permissions

About this article

Cite this article

Sivtsova, P.A., Shepelevich, V.G. Structure and microhardness of rapidly solidified Al-Ni-Cr alloys. Inorg Mater 42, 264–268 (2006). https://doi.org/10.1134/S0020168506030101

Received:

Issue Date:

DOI: https://doi.org/10.1134/S0020168506030101