Abstract

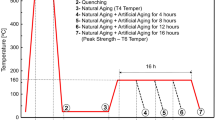

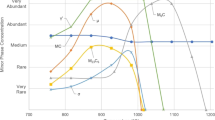

The explosive formability of common age-hardenable Al alloys (2024-T4, 2024-T6, 6061-T4, 6061-T6, 7075-T4, and 7075-T6) is investigated experimentally. Manufacturers utilize explosive forming to produce parts having large and complex geometries in a single operation. To investigate the explosive formability of the most common Al alloys used in the aerospace/aircraft industry, an experimental die design is constructed. Tensile tests are carried out to determine the mechanical behavior of the alloys at low strain rates. Charpy V-notch tests are used as input values to determine the fracture toughness and fracture energy. The strain rate considering the expansion angle is calculated through the analytical formula of the Gurney metal velocity. The strain rates obtained by explosive forming conducted in air are calculated roughly as \(1.1\cdot 10^5\) s\(^{-1}\), which is an extreme rate. The experimental results reveal that the 6061-T4 Al alloy could be explosively formed to the demanded geometry without any hollows, cracks, tearing, and fractured regions. It is clear that the T6 temper condition significantly improves the strength of the tested alloys, accompanied by reduction of ductility and crack initiation potential. Except for the 6061-T4 Al alloy, all of the tested alloys are fractured during explosive forming tests. Stereo microscopy and scanning electron microscopy investigations reveal transgranular fracture and cleavage facets resulting from brittle fracture initiated by high strain rates, which occurs in the peak-strength temper condition-T6 of the tested Al alloys.

Similar content being viewed by others

REFERENCES

M. E. Oakes and S. C. Slotterback, “Too Good to be True: Dose Insensitivity and Stereotypical Thinking of Foods’ Capacity to Promote Weight Gain," Food Quality Preference 16 (8), 675–681 (2005); DOI: 10.1016/j.foodqual.2005.03.010.

B. M. Dobratz and P. C. Crawford, LLNL Explosives Handbook—Properties of Chemical Explosives and Explosive Simulants (Lawrence Livermore Nat. Lab., Livermore, 1985).

R. D. McLeish, “The Application of Explosives to Metal Cutting, Rock Drilling and Controlled Earth Shifting," Int. J. Mech. Sci. 8 (5), 397–409 (1966); DOI: 10.1016/0020-7403(66)90010-5.

Hermetic Solutions Group. Explosive Metal Forming; https://www.hermeticsolutions.com/ wp-content/ uploads/2018/07/explosive-forming-presentation.pdf. (February 27, 2021).

J. R. Davis and S. L. Semiatin, ASM Metals Handbook, Vol. 14: Forming and Forging (ASM Int., 1989).

H. G. Baron and R. H. Henn, “Spring-Back and Metal Flow in Forming Shallow Dishes by Explosives," Int. J. Mech. Sci. 6 (6), 435–444 (1964); DOI: 10.1016/s0020-7403(64)80004-7.

M. Gerdooei, B. M. Dariani, and G. H. Liaghat, “Effect of Material Models on Formability of Sheet Metals in Explosive Forming," in Proc. World Congress Eng., Vol. II (2009), pp. 1741–1746.

A. G. Mamalis, A. Szalay, N. Göbl, et al., “Near Net-Shape Manufacturing of Metal Sheathed Superconductors by High Energy Rate Forming Techniques," Mater. Sci. Eng. B 53 (1/2), 119–124 (1998); DOI: 10.1016/S0921-5107(98)00114-7.

G. Daehn, M. Altynova, V. S. Balanethiram, et al., “High-Velocity Metal Forming—An Old Technology Addresses New Problems," J. Miner. Met. Mater. Soc. 47, 42–45 (1995); DOI: 10.1007/BF03221230.

S. Tanaka, I. Bataev, M. Nishi, et al., “Micropunching Large-Area Metal Sheets Using Underwater Shock Wave: Experimental Study and Numerical Simulation," Int. J. Mach. Tools Manuf. 147, 103457 (2019); DOI: 10.1016/j.ijmachtools.2019.103457.

D. Šunjić and S. Buljan, “Determining the Amount of Explosives in Metal Forming," in Proc. 30th DAAAM Int. Symp. on Intelligent Manufacturing and Automation, 2019, pp. 592–598; DOI: 10.2507/30th.daaam.proceedings.080.

V. Hadavi, J. Z. Ashani, and A. Mozaffari, “Theoretical Calculation of the Maximum Radial Seformation of a Cylindrical Shell under Explosive Forming by a New Energy Approach," J. Mech. Eng. Sci. 226 (3), 576–584 (2012); DOI: 10.1177/0954406211416190.

E. Kowsarinia, Y. Alizadeh, and H. Samareh Salavati Pour, “Theoretical and Experimental Study on the Effects of Explosive Forming Parameters on Plastic Wrinkling of Annular Plates," Int. J. Adv. Manuf. Technol. 67, 877–885 (2013); DOI: 10.1007/s00170-012-4532-2.

R. A. Yildiz, “Investigation of the Explosive Type on the High Strain Forming of OFHC Copper Tube," J. Strain Anal. Eng. Des. 57 (4), (2022); DOI: 10.1177/03093247211021240.

H. Iyama, Y. Higa, M. Nishi, and S. Itoh, “Numerical Simulation of Explosive Forming Using Detonating Fuse," Int. J. Multiphys. 11 (3), 233–244 (2017); DOI: 10.21152/1750-9548.11.3.233.

H. Iyama, M. Nishi, Y. Higa, et al., “Numerical Simulation on Manufacturing of Pressure Vessel for Shock Food Processing Using Explosive Forming," in Proc. ASME 2016 Pressure Vessels and Piping Conf., Vol. 4: Fluid-Structure Interaction (2016); DOI: 10.1115/PVP2016-64020.

M. Nishi, H. Sakaguchi, S. Tanaka, et al. “Research on Explosive Forming of Magnesium Alloy Plate Using Numerical Simulation and Experimental Studies (I)," Sci. Technol. Energ. Mater. 79 (5), 156–159 (2018).

S. M. Ghalehbandi, A. Fallahi Arezoodar, and H. HosseiniToudeshky, “Influence of Aging on Mechanical Properties of Equal Channel Angular Pressed Aluminum Alloy 7075," J. Eng. Manuf. 231 (10), 1803–1811 (2017); DOI: 10.1177/0954405415612370.

H. R. Kim and K. Y. Lee, “Using the Orthogonal Array with Grey Relational Analysis to Optimize the Laser Hybrid Welding of a 6061-T6 Al Alloy Sheet," J. Eng. Manuf. 222 (8), 981–987 (2008); DOI: 10.1243/09544054JEM1070.

L. Zhang, X. Feng, Z. Li, and C. Liu, “FEM Simulation and Experimental Study on the Quenching Residual Stress of Aluminum Alloy 2024," J. Eng. Manuf. 227 (7), 954–964 (2013); DOI: 10.1177/0954405412465232.

J. Y. Cao, C. C. Zhang, Y. F. Xing, and M. Wang, “Pin Plunging Reinforced Refill Friction Stir Spot Welding of Alclad 2219 to 7075 Alloy," J. Mater. Process. Technol. 284, 116760 (2020); DOI: 10.1016/j.jmatprotec.2020.116760.

ASM International Handbook Committee. ASM Handbook, Vol. 04: Heat Treating (ASM Int., 1991).

J. Banhart, C. S. T. Chang, Z. Liang, et al., “Natural Aging in Al–Mg–Si Alloys—A Process of Unexpected Complexity," Adv. Eng. Mater. 12 (7), 559–571 (2010); DOI: 10.1002/adem.201000041.

ASTM E8/E8M. Standard Test Methods for Tension Testing of Metallic Materials (2009).

ASTM E23–18. Standard Test Methods for Notched Bar Impact Testing of Metallic Materials (2018); DOI: 10.1520/E0023-18.

E. Lucon, P. Langenberg, K. Wallin, and H. Pisarski, “The Use of Charpy/Fracture Toughness Correlations in the FITNET Procedure," in Proc. 24th Int. Conf. on Offshore Mechanics and Arctic Engineering (OMAE 2005), Halkidiki, Greece, June 12–17, 2005, pp. 365–368; DOI: 10.1115/OMAE2005-67569.

C. Feng and B. S. Kang, “Young’s Modulus Measurement Using a Simplified Transparent Indenter Measurement Technique," Exp. Mech. 48, 9–15 (2008); DOI: 10.1007/s11340-007-9074-4.

A. K. Hellier, P. P. Chaphalkar, and G. B. Prusty, “Fracture Toughness Measurement for Aluminium 6061-T6 Using Notched Round Bars," in Proc. 9th Australasian Congr. Appl. Mech., Sydney, November 27–29, 2017, pp. 332–339.

A. Hillerborg, M. Modéer, and P. E. Petersson, “Analysis of Crack Formation and Crack Growth in Concrete by Means of Fracture Mechanics and Finite Elements," Cem. Concr. Res. 6 (6), 773–781 (1976); DOI: 10.1016/0008-8846(76)90007-7.

J. E. Kennedy, “Gurney Energy of Explosives: Estimation of the Velocity and Impulse Imparted to Driven Metal," Report No. SC-RR-70-790 (Sandia Lab., 1970).

W. Kury, H. Hornig, E. Lee, et al., “Metal Acceleration by Chemical Explosives," in Proc. 4th Symp. on Detonation (Office of Naval Research ACR-126, 1965), pp. 3–13.

W. Hosford and R. Caddell, Metal Forming. Mechanics and Metallurgy (Cambridge Univ. Press, 2007).

A. Fahem, A. Kidane, and M. A. Sutton, “Mode-I Dynamic Fracture Initiation Toughness Using Torsion Load," Eng. Fract. Mech. 213, 53–71 (2019); 10.1016/j.engfracmech.2019.03.039.

M. Gattu and S. Aala, “Size-Effect Method to Determine Mode-I Fracture Toughness of Aluminium Alloys," Eng. Fract. Mech. 242, 107504 (2021); 10.1016/j.engfracmech.2020.107504.

Y. G. Wang, Z. X. Jiang, and L. L. Wang, “Dynamic Tensile Fracture Behaviours of Selected Aluminum Alloys under Various Loading Conditions," Strain 49 (4), 335–347 (2013); DOI: 10.1111/str.12040.

C. H. Gür and I. K. Yildiz, “Determining the Impact Toughness of Age-Hardened 2024 Al-Alloy by Nondestructive Measurements," in Proc. 16th World Conf. NDT, Montreal, Canada, August 30–September 3, 2004.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizika Goreniya i Vzryva, 2022, Vol. 58, No. 6, pp. 121-134. https://doi.org/10.15372/FGV20220611.

Rights and permissions

About this article

Cite this article

Yildiz, R.A. Explosive Forming of Precipitation-Hardened Aluminum Alloy Tubes. Combust Explos Shock Waves 58, 738–750 (2022). https://doi.org/10.1134/S0010508222060119

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0010508222060119