Abstract

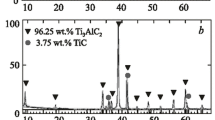

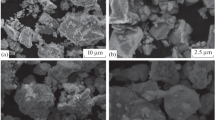

Synthesis products in mechanically activated powder mixtures of titanium and nickel of three compositions corresponding to double intermetallic compounds are studied. The mixtures are mechanically activated in a planetary mill at a rate of 40 g and a processing duration of 20 min. Synthesis is carried out by a thermal explosion: the mechanically activated mixtures are heated in a sealed reactor in an argon atmosphere at an average heating rate of 70°C /min. The phase composition of the powder products after synthesis and additional annealing is studied by X-ray diffraction analysis, and the results are discussed using the reference data on the temperature dependences of the Gibbs energy of intermetallic compounds. It is revealed that, regardless of the elemental composition of the mixtures, the TiNi3 intermetallic compound, which has the highest negative Gibbs energy, is predominantly formed during synthesis. Therefore, a single-phase target product can be obtained only from a TiNi3 mixture. Thermal explosion products in mixtures of the other two compositions are multiphase. Annealing causes no qualitative changes in the phase composition, and the quantitative changes in the phase content are negligible.

Similar content being viewed by others

REFERENCES

State Diagrams of Double Metal Systems, Ed. by N. P. Lyakishev (Mashinostroenie, Moscow, 1998) [in Russian].

Titanium Nickelide Alloys with Shape Memory. Part 1. Structure, Phase Transformations, and Properties, Ed. by V. G. Pushin (Ural Branch of the Russian Acad. of Sci., Yekaterinburg, 2006) [in Russian].

F. Gao and H.-M. Wang, “Abrasive Wear Property of Laser Melting/Deposited Ti2Ni/TiNi Intermetallic Alloy," Trans. Nonferrous Met. Soc. China 17 (6), 1358–1362 (2007); DOI: 10.1016/S1003-6326(07)60277-5.

F. Gao and H. M. Wang, “Effect of TiNi in Dry Sliding Wear of Laser Melt Deposited Ti2Ni/TiNi Alloys," Mater. Charact. 59 (9), 1349–1354 (2008); DOI: 10.1016/j.matchar.2008.05.007.

F. Gao and H. M. Wang, “Dry Sliding Wear Property of a Laser Melting/Deposited Ti2Ni/TiNi Intermetallic Alloy," Intermetallics 16 (2), 202–208 (2008); DOI: 10.1016/j.intermet.2007.09.008.

Y. Zhang, X. Cheng, and H. Cai, “Fabrication, Characterization and Tensile Property of a Novel Ti2Ni/TiNi Micro-Laminated Composite," Mater. Des. 92, 486–493 (2016); DOI: 10.1016/j.matdes.2015.12.014.

Y. Zhang, X. Cheng, H. Cai, et al., “The Effects of Thickness of Original Ti Foils on the Microstructures and Mechanical Properties of Ti2Ni/TiNi Laminated Composites," Mater. Sci. Eng. A. 684, 292–302 (2017); DOI: 10.1016/j.msea.2016.12.070.

C. Velmurugan, V. Senthilkumar, K. Biswas, and S. Yadav, “Densification and Microstructural Evolution of Spark Plasma Sintered NiTi Shape Memory Alloy," Adv. Powder Technol. 29 (10), 2456–2462 (2018); DOI: 10.1016/j.apt.2018.06.026.

L. Krone, E. Schüller, M. Bram, et al., “Mechanical Behaviour of NiTi Parts Prepared by Powder Metallurgical Methods," Mater. Sci. Eng. A 378 (1/2), 185–190 (2004); DOI: 10.1016/j.msea.2003.10.345.

K. Khanlari, Q. Shi, K. Hu, et al., “A Study on the Possibility to Process Dense 60NiTi from Elementally Blended Ni and Ti Powders," Vacuum 192, 110500 (2021); DOI: 10.1016/j.vacuum.2021.110500.

R. Rosa, L. Trombi, A. Casagrande, et al., “On the Versatility and Distinctiveness in the Use of Microwave Energy for the Ignition of Low Exothermic Ni–Ti Intermetallics Combustion Synthesis," Mater. Chem. Phys. 233, 220–229 (2019); DOI: 10.1016/j.matchemphys.2019.05.028.

N. Bertolino, M. Monagheddu, A. Tacca, et al., “Ignition Mechanism in Combustion Synthesis of Ti–Al and Ti–Ni Systems," Intermetallics 11 (1), 41–49 (2003); DOI: 10.1016/S0966-9795(02)00128-0.

P. Novák, L. Mejzlı́ková, A. Michalcová, et al., “Effect of SHS Conditions on Microstructure of NiTi Shape Memory Alloy," Intermetallics 42, 85–91 (2013); DOI: 10.1016/j.intermet.2013.05.015.

M. M. Verdian, K. Raeissi, and M. Salehi, “Electrochemical Impedance Spectroscopy of HVOF-Sprayed NiTi Intermetallic Coatings Deposited on AISI 1045 Steel," J. Alloys Compd. 507 (1), 42–46 (2010); DOI: 10.1016/j.jallcom.2010.07.132.

M. M. Verdian, K. Raeissi, and M. Salehi, “Corrosion Performance of HVOF and APS Thermally Sprayed NiTi Intermetallic Coatings in 3.5% NaCl Solution," Corros. Sci. 52 (3), 1052–1059 (2010); DOI: 10.1016/j.corsci.2009.11.034.

D. C. Ren, H. B. Zhang, Y. J. Liu, et al., “Microstructure and Properties of Equiatomic Ti–Ni Alloy Fabricated by Selective Laser Melting," Mater. Sci. Eng. A 771, 138586 (2020); DOI: 10.1016/j.msea.2019.138586.

Q. Shi, Y. Zhang, C. Tan, et al., “Preparation of Ni–Ti Composite Powder Using Radio Frequency Plasma Spheroidization and Its Laser Powder Bed Fusion Densification," Intermetallics 136, 107273 (2021); DOI: 10.1016/j.intermet.2021.107273.

B. Hosni, C. Khaldi, O. ElKedim, et al., “Electrochemical Properties of Ti2Ni Hydrogen Storage Alloy," Int. J. Hydrogen Energy 42 (2), 1420–1428 (2017); DOI: 10.1016/j.ijhydene.2016.04.032.

B. Hosni, X. Li, C. Khaldi, et al., “Structure and Electrochemical Hydrogen Storage Properties of Ti2Ni Alloy Synthesized by Ball Milling," J. Alloys Compd. 615, 119–125 (2014); DOI: 10.1016/j.jallcom.2014.06.152.

X. Zhao, L. Ma, Y. Ding, and X. Shen, “Structural Evolution and Electrochemical Hydrogenation Behavior of Ti2Ni Alloy," Intermetallics 18 (5), 1086–1090 (2010); DOI: 10.1016/j.intermet.2010.02.016.

M. Balcerzak, J. Jakubowicz, T. Kachlicki, and M. Jurczyk, “Hydrogenation Properties of Nanostructured Ti2Ni-Based Alloys and Nanocomposites," J. Power Sources 280, 435–445 (2015); DOI: 10.1016/j.jpowsour.2015.01.135.

H. T. Takeshita, H. Tanaka, T. Kiyobayashi, et al., “Hydrogenation Characteristics of Ti2Ni and Ti4Ni2X (X = +, N, C)," J. Alloys Compd. 330–332, 517–521 (2002); DOI: 10.1016/S0925-8388(01)01458-X.

H. T. Takeshita, H. Tanaka, N. Kuriyama, et al., “Hydrogenation Characteristics of Ternary Alloys Containing Ti4Ni2X (X = O, N, C)," J. Alloys Compdn. 311 (2), 188–193 (2000); DOI: 10.1016/S0925-8388(00)01118-X.

N. Z. Lyakov, T. L. Talako, and T. F. Grigor’eva, Influence of Mechanical Activation on the Processes of Phase and Structure Formation during Self-Propagating High-Temperature Synthesis (Parallel’, Novosibirsk, 2008) [in Russian].

M. A. Korchagin, “Thermal Explosion in Mechanically Activated Low-Calorific-Value Compositions," Fiz. Goreniya Vzryva 51 (5), 77–86 (2015) [Combust., Expl., Shock Waves 51 (5), 578–586 (2015); DOI: 10.1134/S0010508215050093.

T. F. Grigorieva, A. P. Barinova, and N. Z. Lyakhov, “Mechanochemical Synthesis of Intermetallic Compounds," Usp. Khim. 70 (1), 52–71 (2001) [Russ. Chem. Rev., 70, 45–63 (2001); DOI: 10.1070/RC2001v070n01ABEH000598].

N. V. Bukrina and A. V. Baranovskiy, “Synthesis of Composites Made of Powder Mixtures (Ti, C, and Al) in Controlled Heating," Prikl. Mekh. Tekh. Fiz. 60 (4), 165–173 (2019) [J. Appl. Mech. Tech. Phys. 60 (4), 732–739 (2019); DOI: 10.1134/S0021894419040187].

M. R. Akbarpour, S. Alipour, M. Najafi, et al., “Microstructural Characterization and Enhanced Hardness of Nanostructured Ni3Ti–NiTi (B2) Intermetallic Alloy Produced by Mechanical Alloying and Fast Microwave-Assisted Sintering Process," Intermetallics 131, 107119 (2021); DOI: 10.1016/j.intermet.2021.107119.

L. I. Mirkin, X-ray Diffraction Control of Engineering Materials: Manual (Mashinostroenie, Moscow, 1979) [in Russian].

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizika Goreniya i Vzryva, 2022, Vol. 58, No. 6, pp. 66-74. https://doi.org/10.15372/FGV20220606.

Rights and permissions

About this article

Cite this article

Pribytkov, G.A., Baranovskii, A.V., Korzhova, V.V. et al. Synthesis of Titanium–Nickel Intermetallic Compounds from Mechanically Activated Powder Mixtures. Combust Explos Shock Waves 58, 688–695 (2022). https://doi.org/10.1134/S0010508222060065

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0010508222060065