Abstract

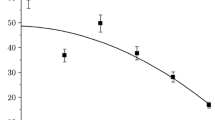

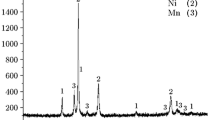

This paper describes the effect of preliminary mechanical activation (MA) and Ti content on maximum temperature, maximum burning rate, composite particle size, mixture yield after MA, sample elongation during combustion, and the phase composition and morphology of combustion products in the Ni–Ti–Al system. The preliminary MA of a Ni + Al + Ti mixture expands the limit of titanium content at which samples can burn without preheating, from 17 to 59% (by weight). Mechanical activation is followed by a drop in the number of phases in the products and an increase in the burning rate, while the maximum synthesis temperature decreases. The augmentation of the Ti content in the Ni + Al + Ti mixture reduces the burning rate and maximum combustion temperature of both initial and mechanically activated mixtures. Moreover, as the titanium content increases, the average size of composite particles decreases and the yield of the activated mixture becomes larger. In the combustion of mechanically activated mixtures with a high (24–52%) titanium content, the Ti2Ni phase and the Ni2TiAl Heusler phase predominate in the products, while the traces of melting are visually observed. In the activated Ni + Al + Ti mixture, the Ti content at which the Heusler phase content in the combustion products becomes maximum is revealed. Most of the observed dependences are explained.

Similar content being viewed by others

REFERENCES

Y. Kopit, “The Ability of Systems Based on Ni, Al and Ti to Be Synthesized by Self-Propagating High-Temperature Synthesis (SHS)," Intermetallics 9 (5), 387–393 (2001); DOI: 10.1016/S0966-9795(01)00013-9.

K. Sidnov and D. S. Belov, “Heusler Phases Ni2AlM (M = Ti, Zr, Hf, Nb) by SHS Method," Int. J. Self-Propag. High-Temp. Synth. 28 (4), 279–280 (2019); DOI: 10.3103/S1061386219040125.

J. Shi, A. Zheng, Z. Lin, et al., “Effect of Process Control Agent on Alloying and Mechanical Behavior of L21 Phase Ni–Ti–Al Alloys," Mater. Sci. Eng. A 740–741, 130–136 (2019); DOI: 10.1016/J.MSEA.2018.10.097.

V. N. Sanin, D. M. Ikornikov, D. E. Andreev, et al., “Cast NiAl/Ni20Al3B6 Composites by Centrifugal SHS," Int. J. Self-Propag. High-Temp. Synth. 23 (4), 232–239 (2014); DOI: 10.3103/S1061386214040098.

V. E. Gyunter, V. I. Itin, L. A. Monasevich, et al., Shape Memory Effects and Their Application in Medicine (Nauka, Novosibirsk, 1992) [in Russian].

J. Banhart, “Manufacture, Characterization and Application of Cellular Metals and Metal Foam," Prog. Mater. Sci. 46 (6), 559–632 (2001); DOI: 10.1016/S0079-6425(00)00002-5.

R. Przeliorz, M. Goral, G. Moskal, and L. Swadzba, “The Relationship Between Specific Heat Capacity and Oxidation Resistance of TiAl Alloys," J. Achiev. Mater. Manuf. Eng. 21 (1), 48–50 (2007).

T. Novoselova, S. Celotto, R. Morgan, et al., “Formation of TiAl Intermetallics by Heat Treatment of Cold-Sprayed Precursor Deposits," J. Alloys Compd. 436 (1/2), 69–77 (2007); DOI: 10.1016/j.jallcom.2006.06.101.

T. Graf, C. Felser, and S. S. P. Parkin, “Simple Rules for the Understanding of Heusler Compounds," Prog. Solid State Chem. 39 (1), 1–50 (2011); DOI: 10.1016/j.progsolidstchem.2011.02.001.

W. Lin and A. J. Freeman, “Cohesive Properties and Electronic Structure of Heusler L21-Phase Compounds Ni2XAl (X = Ti, V, Zr, Nb, Hf, and Ta)," Phys. Rev. B. Condens. Matter. 45 (1), 61–68 (1992); DOI: 10.1103/physrevb.45.61.

P. V. Sreenivasa Reddy and V. Kanchana, “Ab Initio Study of Fermi Surface and Dynamical Properties of Ni2XAl (X = Ti, V, Zr, Nb, Hf and Ta)," J. Alloys Compd. 616, 527–534 (2014); DOI: 10.1016/j.jallcom.2014.07.020.

M. A. Korchagin, T. F. Grigor’eva, B. B. Bokhonov, et al., “Solid-State Combustion in Mechanically Activated SHS Systems. I. Effect of Activation Time on Process Parameters and Combustion Product Composition," Fiz. Goreniya Vzryva 39 (1), 51–59 (2003) [Combust., Expl., Shock Waves 39 (1), 43–50 (2003)].

M. A. Korchagin, “Thermal Explosion in Mechanically Activated Low-Calorific-Value Compositions," Fiz. Goreniya Vzryva 51 (5), 77–86 (2015) [Combust., Expl., Shock Waves 51 (5), 578–586 (2015); DOI: 10.1134/S0010508215050093].

M. A. Korchagin, V. Yu. Filimonov, E. V. Smirnov, and N. Z. Lyakhov, “Thermal Explosion of a Mechanically Activated 3Ni–Al Mixture," Fiz. Goreniya Vzryva 46 (1), 48–53 (2010) [Combust., Expl., Shock Waves 46 (1), 41–46 (2010)].

N. A. Kochetov and S. G. Vadchenko, “Effect of the Time of Mechanical Activation of a Ti + 2B Mixture on Combustion of Cylindrical Samples and Thin Foils," Fiz. Goreniya Vzryva 51 (4), 77–81 (2015) [Combust., Expl., Shock Waves 51 (4), 467–471 (2015); DOI: 10.1134/S0010508215040103].

N. A. Kochetov, “Combustion and Characteristics of Mechanically Activated Ni + Al Mixture: Effects of the Weight and Size of the Milling Balls," Khim. Fiz. 35 (7), 49–54 (2016); DOI: 10.7868/S0207401X16070049 [Russian J. Phys. Chem. B 10, 639–643 (2016)].

S. G. Vadchenko, “Gas Emission During Combustion of Mechanically Activated Ni + Al Mixtures," Int. J. Self-Propag. High-Temp. Synth. 25 (4), 210–214 (2016); DOI: 10.3103/S1061386216040105.

S. G. Vadchenko, “Gas Release during Combustion of Ti + 2B Films: Influence of Mechanical Alloying," Int. J. Self-Propag. High-Temp. Synth. 24 (2), 89–92 (2015); DOI: 10.3103/S1061386215020107.

N. A. Kochetov and B. S. Seplyarskii, “Effect of Initial Temperature and Mechanical Activation on Synthesis in a Ti + Al System," Fiz. Goreniya Vzryva 56 (3), 69–77 (2020) [Combust., Expl., Shock Waves 56 (3), 308–316 (2020); DOI: 10.1134/S0010508220030077].

N. A. Kochetov, B. S. Seplyarskii, and A. S. Shchukin, “Dependences of the Burning Rate and Phase Composition of Condensed Products of a Ti + Ni Mixture on the Mechanical Activation Time," Fiz. Goreniya Vzryva 55 (3), 63–70 (2019) [Combust., Expl., Shock Waves 55 (3), 300–307 (2019); DOI: 10.1134/S0010508219030080].

N. A. Kochetov and B. S. Seplyarsky, “Dependence of Combustion Rates and Maximum Synthesis Temperatures on the Initial Sample Temperature for Initial and Activated Ti + Ni Mixtures," Khim. Fiz. 39 (9), 39–44 (2020); DOI: 10.31857/S0207401X20090058 [Russian J. Phys. Chem. B 14, 791–796 (2020)].

N. A. Kochetov and A. E. Sytschev, “Effects of Magnesium on Initial Temperature and Mechanical Activation on Combustion Synthesis in Ti–Al–Mg System," Mater. Chem. Phys. 257, 123727 (2021); DOI: 10.1016/j.matchemphys.2020.123727.

C. E. Wen et al., “Synthesis of Nanocrystallite by Mechanical Alloying and in situ Observation of Their Combustion Phase Transformation in Al3Ti," J. Mater. Sci. 35, 2099–2105 (2000); DOI: 10.1023/A:1004763713031.

A. S. Rogachev and A. S. Mukasyan, “Combustion of Heterogeneous Nanostructural Systems (Review)," Fiz. Goreniya Vzryva 46 (3), 3–30 (2010) [Combust., Expl., Shock Waves 46 (3), 243–266 (2010)].

I. B. Zel’dovich, G. I. Barenblatt, V. B. Librovich, and G. M. Makhviladze, The Mathematical Theory of Combustion and Explosions (Nauka, Moscow, 1980; Consultants Bureau, 1985).

P. B. Budberg, “Al–Ni–Ti Ternary Phase Diagram Evaluation. Phase Diagrams, Crystallographic and Thermodynamic Data," in MSI Materials Science International Services GmbH (1993); https://materials.springer.com/msi/docs/sm_msi_r_10_ 013824_01.

N. A. Kochetov and B. S. Seplyarskii, “Effect of the Duration of the Mechanical Activation of Granulated Mixtures of 5Ti + 3Si on the Rate of Combustion Wave Propagation and the Elongation of Samples after Synthesis," Zh. Fiz. Khim. 92 (1), 56–61 (2018); DOI: 10.7868/S0044453718010119 [Russian J. Phys. Chem. A 92 (1), 47–52 (2018)].

N. A. Kochetov and B. S. Seplyarskii, “Effect of Mechanical Activation of Granulated and Powdered Ni + Al Mixtures on Flame-Propagation Rates and Sample Elongation in Combustion," Khim. Fiz. 37 (10), 44–50 (2018); DOI: 10.1134/S0207401X18100059 [Russian J. Phys. Chem. B 12, 883–889 (2018)].

N. A. Kochetov and A. E. Sychev, “Effect of Content and Mechanical Activation on the Combustion of a Ni–Al–C System," Fiz. Goreniya Vzryva 55 (6), 58–64 (2019) [Combust., Expl., Shock Waves 55 (6), 686–691 (2019); DOI: 10.1134/S001050821906008X].

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizika Goreniya i Vzryva, 2021, Vol. 57, No. 6, pp. 32-41.https://doi.org/10.15372/FGV20210604.

Rights and permissions

About this article

Cite this article

Kochetov, N.A. Effect of Titanium Content and Mechanical Activation on Ni–Al–Ti Combustion. Combust Explos Shock Waves 57, 663–671 (2021). https://doi.org/10.1134/S0010508221060046

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0010508221060046