Abstract

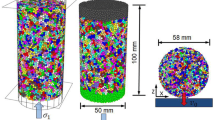

Natural fragmentation of steel cylinders with different charge sizes is investigated, and the correlation of different cylinders is proposed. The Mott fragment distribution has some obvious shortcomings, including the difficulty of accurately determining the number of fragments. Besides, there is no unified and convenient method to describe the fragmentation behavior of shells with different structures. The results show that the fragmentation behavior of the cylinder is self-similar statistically and can be characterized by a new integrated linear formula \(C_L = a + b (C / M)\). Due to the existence of the end face and the charge clearance, the fragmentation performance of the cylinder is reduced to a constant value, and the effect of the wall thickness is small. The influence of the end face and charge clearance on fragmentation is investigated by 3D simulations, and the numerical results ensure good validation of the experimental data.

Similar content being viewed by others

REFERENCES

O. Soto, J. Baum, and R. Löhner, “An Efficient Fluid—Solid Coupled Finite Element Scheme for Weapon Fragmentation Simulations," Eng. Fract. Mech. 77 (3), 549–564 (2010); https://doi.org/10.1016/j.engfracmech.2009.11. 003.

H. Y. Grisaro, D. Benamou, and A. N. Dancygiera, “Investigation of Blast and Fragmentation Loading Characteristics—Field Tests," Eng. Struct. 167, 363–375 (2018); https:/doi.org/10.1016/ j.engstruct.2018.04.013.

W. Arnold and E. Rottenkolber, “Fragment Mass Distribution of Metal Cased Explosive Charges," Int. J. Impact. Eng. 35(12), 1393–1398 (2008); https://doi.org/ 10.1016/j.ijimpeng.2008.07.049.

Z. X. Shen, H. Yang, Y. Z. Li, et al., “Influence of Localized Melting on Dynamic Fracture Behaviours of Metallic Shell," Propell., Explos., Pyrotech. 42 (8), 906–911 (2017). https://doi.org/10.1002/prep.201700051.

R. W. Gurnery, The Initial Velocities of Fragments from Bombs, Shells and Grenades (US Army Ballistic Research Lab. Aberdeen Proving Ground, 1943).

G. I. Taylor, Analysis of the Explosion of a Long Cylindrical Bomb Detonated at One End (Cambridge Univ. Press, Cambridge, 1963).

R. H. Hoggatt and R. F. Recht, “Fracture behavior of Tubular Bombs," J. Appl. Phys. 39 (3), 1856–1862 (1968); https://doi.org/ 10.1063/1.1656442.

N. F. Mott, “Fragmentation of Shell Cases," Proc. Roy. Soc. London, A 189, 300–308 (1947); https://doi.org/10.1098/rspa.1947.0042.

D. E. Grady and M. M. Hightower, Natural Fragmentation of Exploding Cylinders (Sandia Nat. Lab., Albuquerque, 1990).

T. Hiroe, K. Fujiwara, H. Hata, and H. Takahashi, “Deformation and Fragmentation behavior of Exploded Metal Cylinders and the Effects of Wall Materials, Configuration, Explosive Energy and Initiated Locations," Int. J. Impact. Eng. 35 (12), 1578–1586 (2008); https://doi.org/10.1016/j.ijimpeng.2008.07.002.

G. Tanapornraweekit and W. Kulsirikasem, “Effects of Material Properties of Warhead Casing on Natural Fragmentation Performance of High Explosive (HE) Warhead," World Acad. Sci., Eng. Technol.66, 411–415 (2012); https://doi.org/10.5281/zenodo.1063194.

X. S. Kong, W. G. Wu, J. Li, et al., “A Numerical Investigation on Explosive Fragmentation of Metal Casing Smoothed Particle Hydrodynamic Method," Mater. Des. 51, 729–741 (2013); https://doi.org/10.1016/j.matdes.2013.04.041.

I. G. Cullis et al., “Numerical Simulation of the Natural Fragmentation of Explosively Loaded Thick Walled Cylinders," Def. Technol. 10, 198–210 (2014); https://doi.org/ 10.1016/j.dt.2014.06.003.

J. F.Moxnes, A. K. Prytz, O. Froyland, et al., “Strain Rate Dependency and Fragmentation Pattern of Expanding Warheads," Def. Technol. 11, 1–9 (2015); https://doi.org/10.1016/j.dt.2014.08.006.

B. Zecevic, J. Terzic, A. Catovic, and S. K. Sabina, “Influence Parameters on HE Projectiles with Natural Fragmentation," New Trends Res. Energ. Mater. 780–795 (2006).

V. M. Gold and E. L. Baker, “A Model for Fracture of Explosively Driven Metal Shells," Eng. Fract. Mech. 75 (2), 275–289 (2008); https://doi.org/10.1016/j.engfracmech.2007.02. 025.

P. Elek and S. Jaramaz, “Modeling of Fragmentation of Rapidly Expanding Cylinders," Theor. Appl. Mech. 32 (2), 113–130 (2005); https://doi.org/10.2298/TAM0502113E.

D. E. Grady, “Length Scales and Size Distributions in Dynamic Fragmentation," Int. J. Fract. 163, 85–99 (2010); https://doi.org/ 10.1007/s10704-009-9418-4.

N. F. Mott, “Fragmentation of H.E. Shells: A Theoretical Formula for the Distribution of Weights of Fragments," Fragm. Rings Shells, 227–241 (2006); https://doi.org/ 10.1007/978-3-540-27145-1_10.

B. E. Walsh, Comparison of Natural Fragmentation Scaling behavior of HF-1 and AISI 1045 Steel Cylinders Using Normalized Payman Parameters (DSTO Mater. Res. Lab., Ascot Vale, Vic., Australia, 1984).

W. D. Reid and B. E. Walsh, “Dynamic Fracture Properties of a Tungsten, 3.5% Ni, 1.5% Fe Alloy under Explosive Loading Conditions," J. Phys. IV France 1 (C3), 597–604 (1991); https://doi.org/10.1051/jp4:1991384.

A. V. Gerasimov, “Explosive Deformation and Fracture of Thick-Wall Cylinders," Strength Mater. 35, 162–167 (2003); https://doi.org/10.1023/A:1023714612432.

H. Grisaro and A. N. Dancygier, “Numerical Study of Velocity Distribution of Fragments Caused by Explosion of a Cylindrical Cased Charge," Int. J. Impact. Eng. 86, 1–12 (2015); https://doi.org/10.1016/j.ijimpeng.2015.06.024.

Z. B. Zhang, F. L. Huang, Y. Cao, and C. Yan, “A Fragments Mass Distribution Scaling Relations for Fragmenting Shells with Variable Thickness Subjected to Internal Explosive Loading," Int. J. Impact. Eng. 120, 79–94 (2018); https://doi.org/10.1016/j.ijimpeng.2018.05.013.

Z. W. Guo, G. Y. Huang, W. Zhu, et al., “Mechanism and Suppression of the Effect of Axial Rarefaction Waves on the Eccentric Initiation Effect," Int. J. Impact. Eng. 124, 37–47 (2019); https://doi.org/ 10.1016/j.ijimpeng.2018.10.009.

G. Y. Huang, W. Li, and S. S. Feng, “Axial Distribution of Fragment Velocities from Cylindrical Casing under Explosive Loading," Int. J. Impact. Eng. 76, 20–27 (2015); https://doi.org/10.1016/j.ijimpeng.2014.08.007.

ANSYS Fluent User’s Guide, Release 15.0(Canonsburg, 2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizika Goreniya i Vzryva, 2021, Vol. 57, No. 2, pp. 132–142.https://doi.org/10.15372/FGV20210214.

Rights and permissions

About this article

Cite this article

Shen, ZX., Huang, HD., Cen, ZB. et al. Natural Fragmentation Behavior of Steel Cylinders with Variable Charge Geometries under Detonation Loading. Combust Explos Shock Waves 57, 246–255 (2021). https://doi.org/10.1134/S0010508221020143

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0010508221020143