Abstract

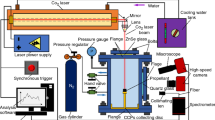

Composite propellants are tested using the quench particle collection bomb (QPCB) for the pressure ranging from 2 to 8 MPa to estimate the particle size distribution of aluminum agglomerates from quenched combustion residues emerged out from the burning surface. The major ingredients included in the propellants are ammonium perchlorate (AP), aluminum (Al), hydroxyl-terminated polybutadiene (HTPB), and toluene diisocyanate (TDI). Five propellant compositions are considered in this study; two of them are mixed with catalysts. Propellant formulation variables like the coarse AP/fine AP ratio, total solid loading, catalyst percentage, and aluminum content are varied to assess their effects on the aluminum agglomeration process at different pressures. Unburnt aluminum in agglomerates is continuously getting combusted as they move out from the propellant burning surface. Large agglomerates comprise both Al2O3 and unburnt aluminum. The majority of agglomerates are spherical in shape, and the sizes vary from 31 to 115 \(\mu\)m for non-catalyzed propellants and from 28 to 136 \(\mu\)m for catalyzed propellants over the tested pressure conditions. These results can give further insight into the aluminum agglomeration process of catalyzed and non-catalyzed propellants and also affect the choice of the propellant ingredient percentage aimed at reducing aluminum agglomeration, which causes two-phase flow losses of thrust and slag accumulation in full-scale solid rocket motors.

Similar content being viewed by others

REFERENCES

P. Bucher, L. Ernst, F. L. Dryer, et al., “Detailed Studies on the Flame Structure of Aluminum Particle Combustion," Prog. Astronaut. Aeronaut. 185. 689–722 (2000); https://doi.org/10.2514/5.9781600866562.0689. 0722.

E. W. Price, “Experimental Solid Rocket Combustion Instability," Symp. (Int.) on Combustion 10 (1), 1067–1082 (1965); https://doi.org/10.1016/s0082-0784(65)80247-8.

M. W. Beckstead, “A Summary of Aluminum Combustion," inRTO/VKI Special Course on Internal Aerodynamics in Solid Rocket Propulsion, RTO-EN-023-5 (2002), pp. 1–46.

E. W. Price and R. K. Sigman, “Combustion of Aluminized Solid Propellants," Prog. Astronaut. Aeronaut. 185, 663–687 (2000); https://doi.org/10.2514/5.9781600866562.0689.0722.

R. W. Hermsen, “Aluminum Oxide Particle Size for Solid Rocket Motor Performance Prediction," J. Spacecr. Rockets. 18(6), 483–490 (1981); https://doi.org/10.2514/3.57845.

T. R. Sippel, S. F. Son, and L. J. Groven, “Aluminum Agglomeration Reduction in a Composite Propellant using Tailored Al/PTFE Particles," Combust. Flame 161 (1), 311–321 (2014); https://doi.org/10.1016/ j.combustflame.2013.08.009.

H. Cheung and N. S. Cohen, “Performance of Solid Propellants Containing Metal Additives," AIAA J. 3 (2), 250–257 (1965); https://doi.org/10.2514/3.2838.

F. Maggi, A. Bandera, L. Galfetti, et al., “Efficient Solid Rocket Propulsion for Access to Space," Acta Astronaut. 66(11/12), 1563–1573 (2010); https://doi.org/10.1016/j.actaastro.2009.10.012.

R. A. Geisler, “Global View of the use of Aluminum Fuel in Solid Rocket Motors," in 38th AIAA/ASME/SAE/ASEE Jt. Propul. Conf. Exhib. (2002); https://doi.org/10.2514/6.2002-3748.

T. R. Sippel, S. F. Son, L. J. Groven, et al., “Exploring Mechanisms for Agglomerate Reduction in Composite Solid Propellants with Polyethylene Inclusion Modified Aluminum," Combust. Flame162 (3), 846–854 (2015); https://doi.org/10.1016/j.combustflame.2014.08.013.

L. A. Povinelli and R. A. Rosenstein, “Alumina Size Distributions from High-Pressure Composite Solid-Propellant Combustion," AIAA J. 2 (10), 1754–1760 (1964); https://doi/10.2514/3.2660.

E. W. Price, R. K. Sigman, J. R. Sambamurthi, and C. J. Park, “Behavior of Aluminum in Solid Propellant Combustion," AFOSR-TR-82-0964 (Georgia Inst. of Technology, 1982).

J. K. Sambamurthi, E. W. Price, and R. K. Sigman, “Aluminum Agglomeration in Solid-Propellant Combustion," AIAA J.22 (8), 1132–1138 (1984); https://doi.org/ 10.2514/3.48552.

D. Laredo and D. W. Netzer, “Application of Optical Diagnostics to Particle Measurements in Solid Propellant Rocket Motors and Exhaust Plumes," Part. Sci. Technol. 11 (3/4), 175–192 (1993); https://doi.org/ 10.1080/02726359308906633.

D. Laredo, J. D. McCrorie II, J. K. Vaughn, and D. W. Netzer, “Motor and Plume Particle Size Measurements in Solid Propellant Micromotors," J. Propul. Power 10 (3), 410–418 (1994); https://doi.org/10.2514/3.23750.

V. V. Karasev, A. A. Onischuk, O. G. Glotov, et al., “Formation of Charged Aggregates of Al2O3 Nanoparticles by Combustion of Aluminum Droplets in Air," Combust. Flame138 (1/2), 40–54 (2004); https:// doi.org/10.1016/j.combustflame.2004.04.001.

F. Cauty, C. J. Eradès, and J.-M. Desse, “Light Deviation Based Optical Techniques Applied to Solid Propellant Combustion," Prog. Propul. Phys. 2, 121–134 (2011); https://doi.org/10.1051/eucass/201102121.

J. P. Powers and D. W. Netzer, “Automatic Particle Sizing from Rocket Motor Holograms," Practical Holography VI. 136–145 (1992); https://doi.org/10.1117/12.59628.

J. D. Walker, “Holographic Investigation of Metallized Solid Propellant Combustion in Two-Dimensional and Three-Dimensional Rocket Motors," M. S. Thesis (Naval Postgraduate School, Monterey, 1987).

A. G. Butler, “Holographic Investigation of Solid Propellant Combustion," M. S. Thesis (Naval Postgraduate School, Monterey, 1988).

D. E. Faber, “Holographic Investigation of Solid Propellant Combustion Particulates," M. S. Thesis (Naval Postgraduate School, Monterey, 1983).

D. R. Guildenbecher, M. A. Cooper, W. Gill, et al., “Quantitative, Three-Dimensional Imaging of Aluminum Drop Combustion in Solid Propellant Plumes via Digital in-LOine Holography," Opt. Lett.39 (17), 5126–5129 (2014); https://doi.org/10.1364/ol.39.005126.

L. T. DeLuca, “Overview of Al-Based Nanoenergetic Ingredients for Solid Rocket Propulsion," Def. Technol. 14 (5), 357–364 (2018); https://doi:10.1016/j.dt.2018.06.005.

V. A. Babuk, N. L. Budnyi, A. N. Ivonenko, and A. A. Nizyaev, “Simulation of Characteristics of Condensed Products in a Combustion Chamber," Fiz. Goreniya Vzryva 54 (3), 55–63 (2018) [Combust., Expl., Shock Waves 54 (3), 301–308 (2018); https://doi.org/10.1134/s0010508218030061].

M. W. Tanner, “Multidimensional Modeling of Solid Propellant Burning Rates and Aluminum Agglomeration and One-Dimensional Modeling of RDX/GAP and AP/HTPB," Ph.D. Thesis (Brigham Young Univ., 2008).

L. T. DeLuca, F. Maggi, S. Dossi, et al., “High-Energy Metal Fuels for Rocket Propulsion: Characterization and Performance," Huozhayao Xuebao/Chin. J. Explos. Propell. 2013 (6), 1–14 (2013).

O. G. Glotov, “Condensed Combustion Products of Aluminized Propellants. II. Evolution of Particle Distance from the Burning Surface," Fiz. Foreniya Vzryva 36 (4), 66–78 (2000) [Combust., Expl., Shock Waves 36 (4), 476–487 (2000); https://doi.org.10.1007/BF02699478].

J. Yuan, J. Liu, Y. Zhou, et al., “Aluminum Agglomeration of AP/HTPB Composite Propellant," Acta Astronaut. 156, 14–22 (2018); https://doi.org/10.1016/j.actaastro.2018.11.009.

T.-K. Liu, H.-C. Perng, S.-P. Luh, and F. Liu, “Aluminum Agglomeration in Ammonium Perchlorate/Cyclotrimethylenetrinitramine/Aluminum/Hyd- roxy-Terminatedpolybutadiene Propellant Combustion," J. Propul. Power 8 (6), 1177–1184 (1992); https://doi.org/ 10.2514/3.11459.

T.-K. Liu, “Experimental and Model Study of Agglomeration of Burning Aluminized Propellants," J. Propul. Power.21 (5), 797–806 (2005); https://doi.org/10.2514/1.11988.

V. A. Babuk, A. N. Ivonenko, and A. A. Nizyaev, “Calculation of the Characteristics of Agglomerates during Combustion of High-Energy Composite Solid Propellants," Fiz. Goreniya Vzryva51 (5), 44–56 (2015) [Combust., Expl., Shock Waves51 (5), 549–559 (2015); https://doi.org.10.1134/s0010508215050056].

O. G. Glotov, “Condensed Combustion Products of Aluminized Propellants. IV. Effect of the Nature of Nitramines on Aluminum Agglomeration anc Combustion Efficiency," Fiz. Goreniya Vzryva42 (4), 78–92 (2006) [Combust., Expl., Shock Waves42 (4), 436–449 (2006); https://doi.org/10.1007/s10573-006-0073-z].

K. V. Anand, A. Roy, T. Mulla, et al., “Experimental Data and Model Predictions of Aluminium Agglomeration in Ammonium Perchlorate-Based Composite Propellants Including Plateau-Burning Formulations," Proc. Combust. Inst. 34 (2), 2139–2146 (2013); https://doi.org/10.1016/j.proci.2012.07.024.

S.-T. Lee, E. W. Price, and R. K. Signan, “Effect of Multidimensional Flamelets in Composite Propellant Combustion," J. Propul. Power 10 (6), 761–768 (1994); https://doi.org/10.2514/3.23813.

K. Jayaraman, S. R. Chakravarthy, and R. Sarathi, “Quench Collection of Nano-Aluminium Agglomerates from Combustion of Sandwiches and Propellants," Proc. Combust. Inst. 33(2), 1941–1947 (2011); https:// doi.org/10.1016/j.proci.2010.06.047.

S. Isert, C. D. Lane, I. E. Gunduz, and S. F. Son, “Tailoring Burning Rates Using Reactive Wires in Composite Solid Rocket Propellants," Proc. Combust. Inst. 36 (2), 2283–2290 (2017); https://doi.org/10.1016/ j.proci.2016.06.141.

F. Maggi, S. Dossi, and L. T. DeLuca, “Combustion of Metal Agglomerates in a Solid Rocket Core Flow," Acta Astronaut.92 (2), 163–171 (2013); https://doi.org/10.1016/j.actaastro.2012.04.036.

J. C. Mullen and M. Q. Brewster, “Reduced Agglomeration of Aluminum in Wide-Distribution Composite Propellants," J. Propul. Power27 (3), 650–661 (2011); https://doi.org/10.2514/1.50127.

F. Maggi, A. Bandera, and L. T. DeLuca, “Approaching Solid Propellant Heterogeneity for Agglomerate Zize Prediction," in46th AIAA/ASME/SAE/ASEE Jt. Propul. Conf. Exhibit., (2010), pp. 1–11; https://doi.org/ 10.2514/6.2010-6751.

X. Liu, W. Ao, H. Liu, and P. Liu, “Aluminum Agglomeration on Burning Surface of NEPE Propellants at 3–5 MPa," Propell., Explos., Pyrotech. 42 (3), 260–268 (2016); https://doi.org/10.1002/prep.201600131.

K. Kishore, V. R. P. Verneker, and M. R. Sunitha, “Effect of Catalyst Concentration on Burning Rate of Composite Solid Propellants," AIAA J. 15 (11), 1649–1651 (1977); https://doi.org/10.2514/3.7466.

V. Weiser, A. Franzin, V. Gettwert, and L. T. DeLuca, “Combustion of Metallised ADN/GAP Solid Rocket Propellants with Focus on Agglomeration Effects," in 5th Eur. Conf. for Aeronautics and Space Sciences (EUCASS), 2013).

L. Xiao, J. Liu, G. Hao, et al., “Preparation and Study of Ultrafine Flake-Aluminum with High Reactivity," Def. Technol.13 (4), 234–238 (2017); https://doi.org/10.1016/j.dt.2017.05.008.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizika Goreniya i Vzryva, 2021, Vol. 57, No. 2, pp. 82–95.https://doi.org/10.15372/FGV20210209.

Rights and permissions

About this article

Cite this article

Tejasvi, K., Venkateshwara Rao, V., PydiSetty, Y. et al. Studies on Aluminum Agglomeration and Combustion in Catalyzed Composite Propellants. Combust Explos Shock Waves 57, 203–214 (2021). https://doi.org/10.1134/S001050822102009X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S001050822102009X