Abstract

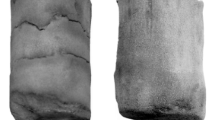

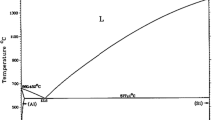

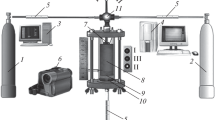

It has been shown that Ti–Al–N ternary compounds, belonging to MAX phases (ceramic materials that can be processed as metals) can be produced by combustion of a granular powder of T65Yu35 (TiAl) alloy in nitrogen flow at a pressure close to atmospheric pressure. Combustion is accompanied by transfer of part of the aluminum through the gas phase. The propagation velocity of the combustion zone and the maximum temperature increase with increasing flow rate.

Similar content being viewed by others

References

M. W. Barsoum and T. El-Raghy, “The MAX Phases: Unique New Carbide and Nitride Materials,” Amer. Scient. 89 (4), 334–343 (2001).

A. T. Procopio, M. W. Barsoum, and T. El-Raghy, “Characterization of Ti4AlN3,” Metallurg. Mater. Trans. A 31 (2), 333–337 (2000).

A. T. Procopio, T. El-Raghy, and M. W. Barsoum, “Synthesis of Ti4AlN3 and Phase Equilibria in the Ti–Al–N System,” Metallurg. Mater. Trans. A 31 (2), 373–378 (2000).

Ming Yan, Bingchu Mei, Jiaoqun Zhu, Chenguang Tian, and Ping Wang, “Synthesis of High-Purity Bulk Ti2AlN by Spark Plasma Sintering (SPS),” Ceram. Int. 34, 1439–1442 (2008).

Ming Yan, Yan-lin Chen, Bing-chu Mei, and Jiao-qun Zhu, “Synthesis of High-Purity Ti2AlN Ceramic by Hot Pressing,” Trans. Nonferrous Metals Soc. China 18, 82–85 (2008).

Z. J. Lin, M. J. Zhuo, M. S. Li, J. Y. Wang, and Y. C. Zhou, “Synthesis and Microstructure of Layered- Ternary Ti2AlN Ceramic,” Scripta Mater. 56, 1115–1118 (2007).

H. Mabuchi, H. Tsuda, Y. Nakayama, and E. Sukedai, “Processing of TiAl–Ti2AlN Composites and Their Compressive Properties,” J. Mater. Res. 7, 894–900 (1992).

A. A. Kondakov and V. V. Grachev, “Combustion Modes of Ternary System Titanium–Aluminum–Nitrogen,” in Book of Abstracts of XII Int. Symp. on Self-Propagating High-Temperature Synthesis, South Padre Island, Oct. 2013, pp. 27–28.

L. Chlubny, J. Lis, and M. M. Bucko, “Influence of Precursors Stoichiometry on SHS Synthesis of Powders of Multilayered Materials in the Ti–Al–C–N System,” in Book of Abstracts of XII Int. Symp. on Self- Propagating High-Temperature Synthesis, South Padre Island, Oct. 2013, pp. 201–202.

A. A. Kondakov and V. V. Grachev, “Filtration Combustion Modes of the Titanium–Aluminum–Nitrogen System,” in Proc. of the Third Conf. on Filtration Combustion, Chernogolovka, 18–21 June, 2013, pp. 35–38.

J. Lis, L. Chlubny, M. Łopacinski, L. Stobierski, and M. Bucko, “Ceramic Nanolaminates—Processing and Application,” J. Europ. Ceram. Soc. 28 (5), 1009–1014 (2008).

K. Y. Wang, “Thermal Behaviours of Mechanically Alloyed Ti50Al50 in a Nitrogen Atmosphere,” J. Mater. Sci. 30, 5427–5432 (1995).

S. A. Firstov, V. P. Gorban, I. I. Ivanova, and E. P. Pechkovskii, “Mechanical Properties of Ti3SiC2/TiC, Ti3AlC2/TiC and Ti4AlN3/TiN Porous Composite Nanolaminates in the Temperature Range of 20–1300°C,” Poroshk. Metallurgiya, No. 7/8, 56–68 (2010).

Zhou Yi, Sun ong-Li, Jiang De-Peng, Han Xiu-Li, Qing Wang, and Wu Gao-Hui, “Microstructural Characteristics and Evolution of Ti2AlN/TiAl Composites with a Network Reinforcement Architecture during Reaction Hot Pressing Process,” Mater. Characterization 80, 28–35 (2013).

J. Magnan, G. C. Weatherly, and M.-C. Cheynet, “The Nitriding Behavior of Ti–Al Alloys at 1000 °C,” Metallurg. Mater. Trans. A 30 (1), 19–29 (1999).

A. P. Aldushin and A. G. Merzhanov, “Theory of Filtration Combustion: General Concepts and State of Research,” in Propagation of Heat Waves in Heterogeneous Media, Ed. by Yu. Sh. Matros (Nauka, Novosibirsk. 1988) [in Russian].

B. S. Seplyarskii, A. G. Tarasov, and P. A. Kochetkov, “Experimental Investigation of Combustion of a Gasless Pelletized Mixture of Ti + 0.5C in Argon and Nitrogen Coflows,” Fiz. Goreniya Vzryva 49 (5), 55–63 (2013)

B. S. Seplyarskii, A. G. Tarasov, and P. A. Kochetkov, Combust., Expl., Shock Waves 49 (5), 555–562 (2013).

B. Sh. Braverman, Yu. M. Maksimov, and Yu. V. Tsybulnik, “Possibility of Nitriding Industrial Ferroalloys in a Nitrogen-Containing Gas Flow,” Fiz. Goreniya Vzryva 48 (6), 87–88 (2012)

B. Sh. Braverman, Yu. M. Maksimov, and Yu. V. Tsybulnik, Combust., Expl., Shock Waves 48 (6), 734–735 (2012).

B. Sh. Braverman and Yu. V. Tsybulnik, “Combustion of Chromium–Aluminum Alloys in Nitrogen,” in Proc. VII All-Russian Sci. Conf., Tomsk, 2011, pp. 74–75.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © B.Sh. Braverman, O.K. Lepakova, Yu.M. Maksimov, Yu.V. Tsybul’nik, V.D. Kitler.

Published in Fizika Goreniya i Vzryva, Vol. 51, No. 4, pp. 66–71, July–August, 2015.

Rights and permissions

About this article

Cite this article

Braverman, B.S., Lepakova, O.K., Maksimov, Y.M. et al. Combustion of TiAl alloy in nitrogen. Combust Explos Shock Waves 51, 457–461 (2015). https://doi.org/10.1134/S0010508215040085

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0010508215040085